-

- EV Motor Manufacturing Assembly Line

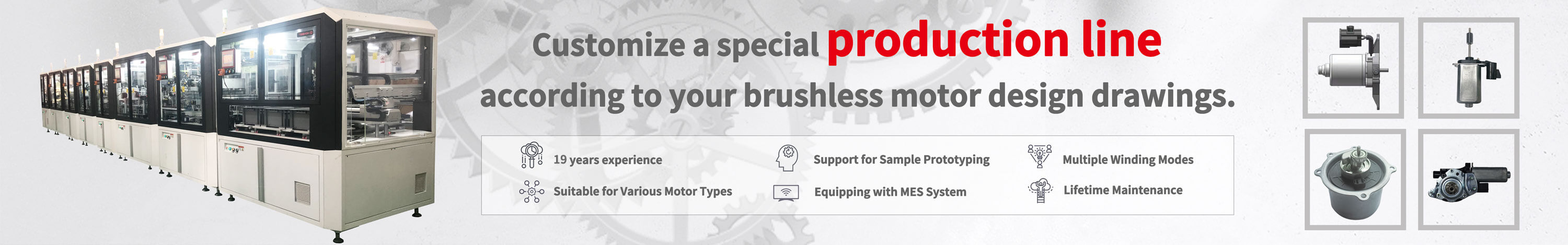

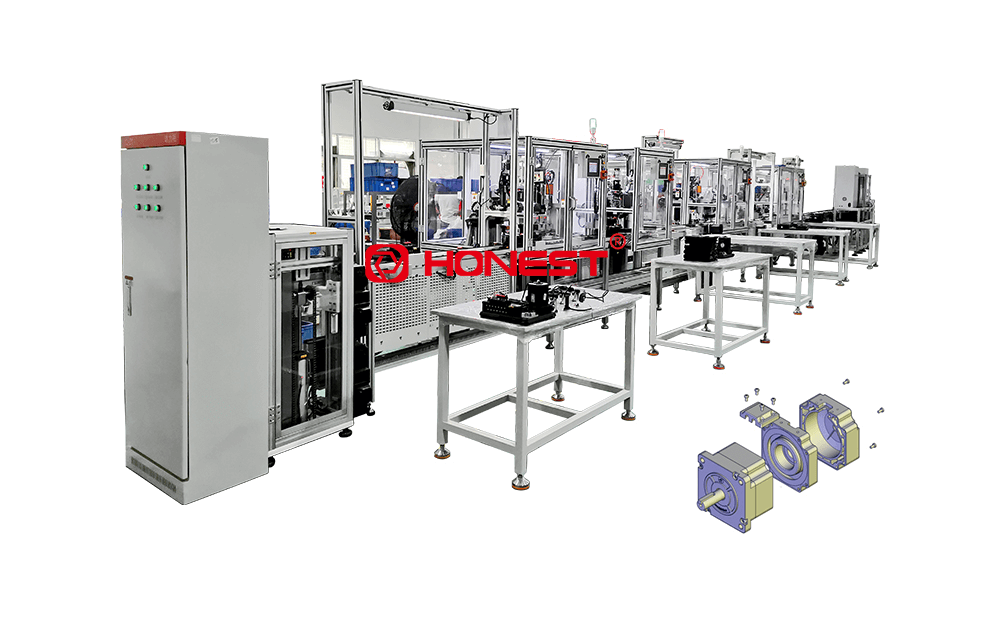

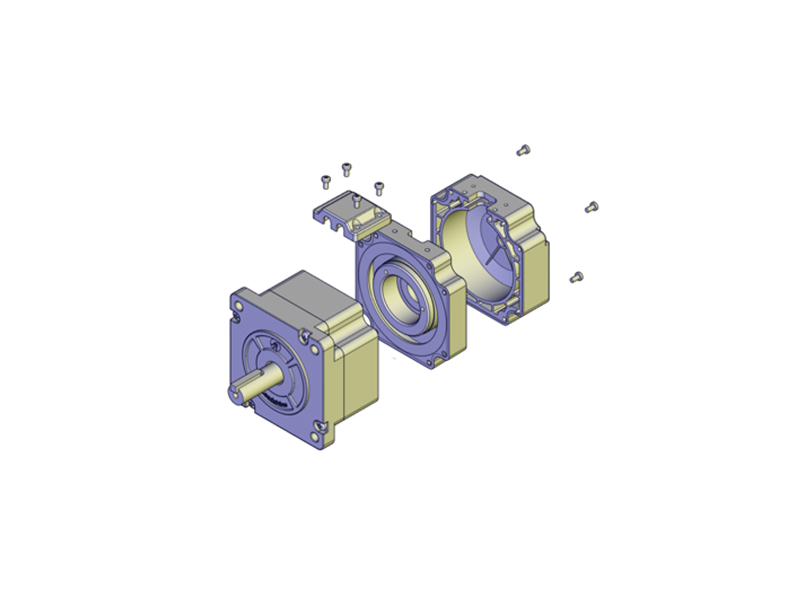

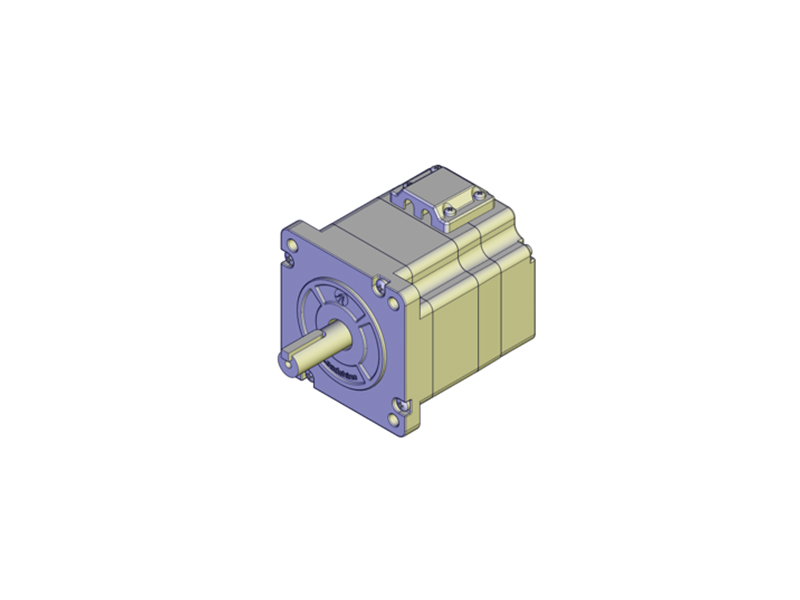

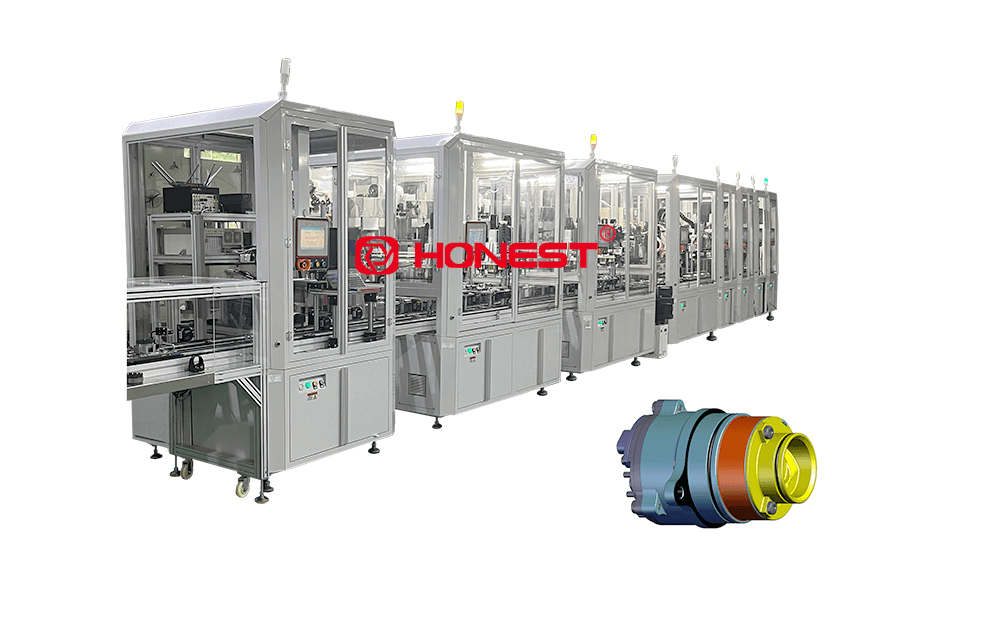

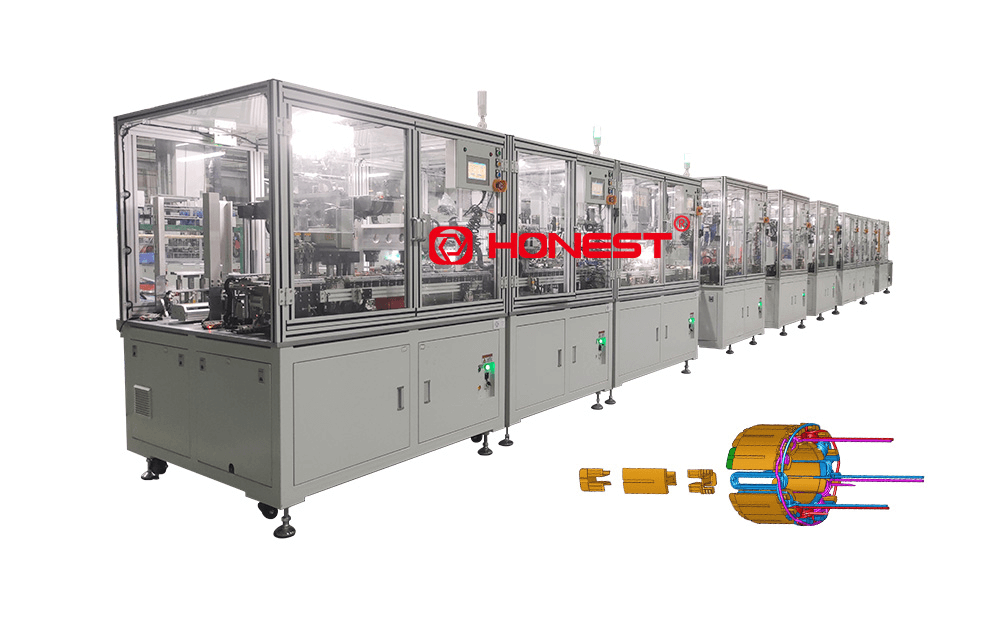

- BLDC Motor Assembly Line

- Stator Assembly Line

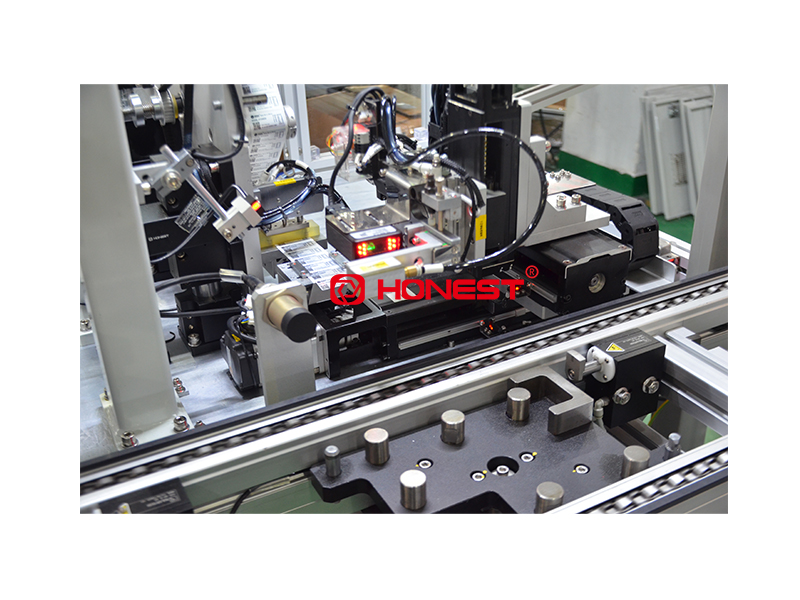

- Rotor Magnet Inserting Machine

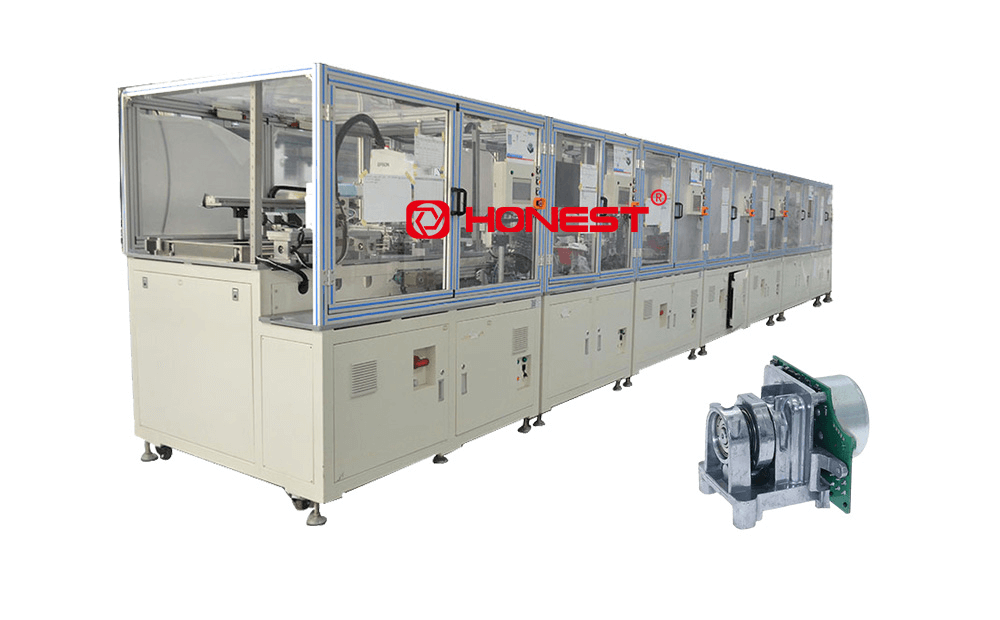

- Brush Motor Assembly Line

- Inductor Winding Machine

- Motor Winding Machine

- Non-Cutting Hairpin Stator Twisting Machine

- Drive Motor Stator Production Line

- Hairpin Stator Assembly Line

- X-pin Motor Stator Production Line

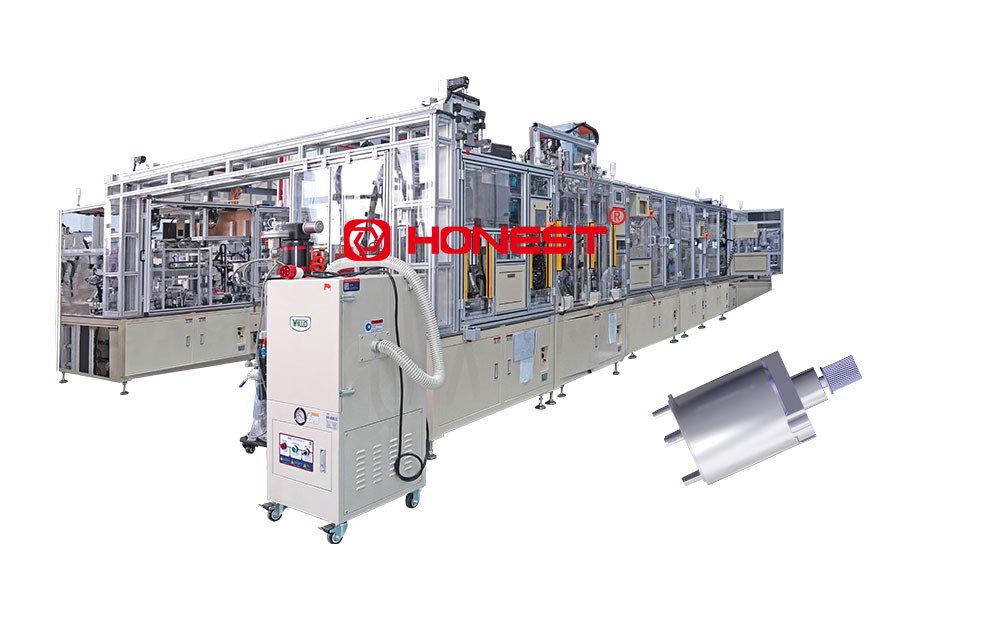

- Drive Traction Motor Assembly Line

- Hairpin Motor Stator Winding & Assembly Line

- Hairpin Motor Automatic Production Line

- Automobile Generator 48V BSG Motor Stator Assembly Line

- Humanoid Robot Actuator Frameless Torque Motor Assembly Line

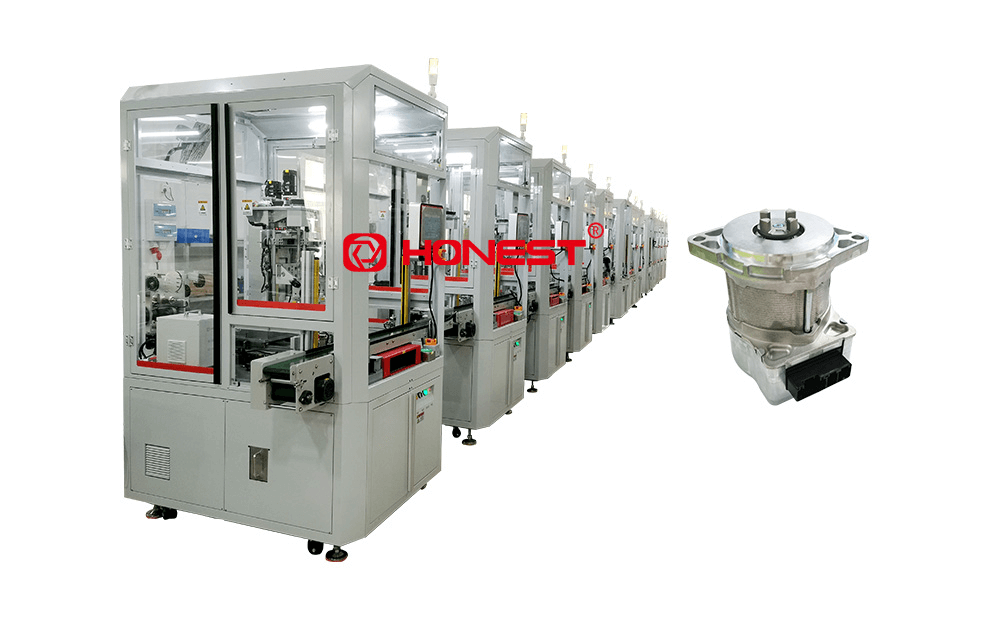

- Automotive EPS Motor Production Line

- Urea Pump Motor Assembly Line

- Electronic Oil Pump Motor Assembly Line

- Automotive EPS Motor Assembly Line

- Automotive Electronic Oil Pump Production Line

- EHPS System Motor Assembly Line

- Automobile Fan Motor Assembly Line

- Segmented Stator Production Line

- Automobile SBW Motor Stator Assembly Line

- Automotive Compressor Motor Assembly Line

- Commercial Vehicle Water Pump Stator Assembly Line

- EPS Motor Stator Production Line

- Split Motor Compressor Stator Assembly Line

- Automobile Air Pump Brushless Motor Stator Production Line

- Automotive Water Pump Brushless Motor Stator Assembly Line

- Rotor Magnet Insert Magnetization Equipment

- BLDC Rotor Magnet Insertion Assembly Line

- Motor Rotor Magnet Insertion Machine

- Rotor Magnet Assembly Machine

- Brushless Motor Rotor Assembly Line

- Electric Vehicle Motor Rotor Assembly Line

- Seat Recliner Motor Assembly Line

- Automotive Air Suspension Motor Production Line

- Automotive Seat Motor Production Line

- Automobile Electric Sunroof Motor Assembly Line

- Automobile Water Pump Motor Assembly Line

- Power Window Motor Production Line

- 370 Motor Assembly Line

- Power Seat Recliner Motor Production Line