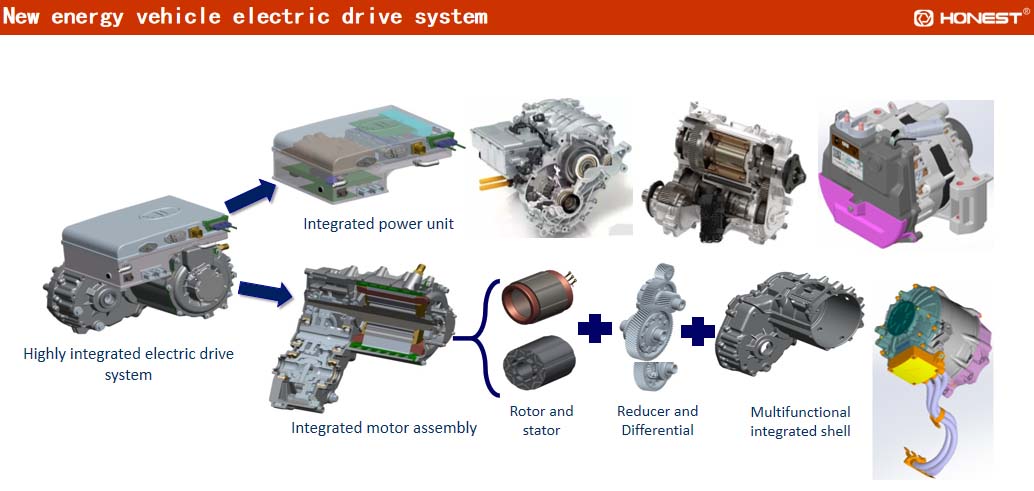

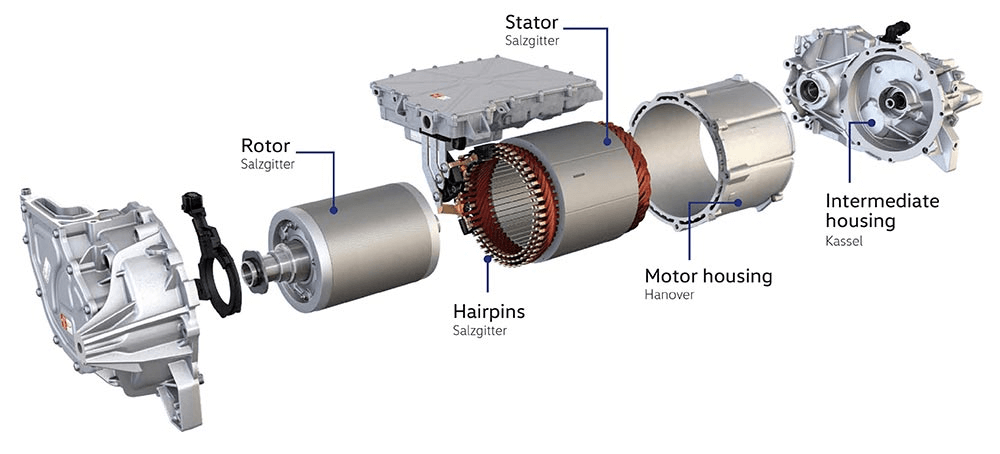

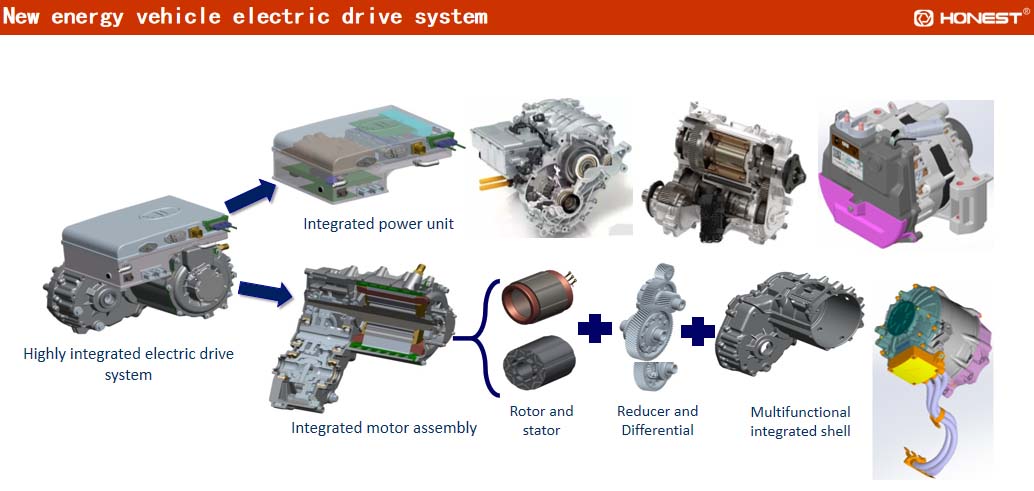

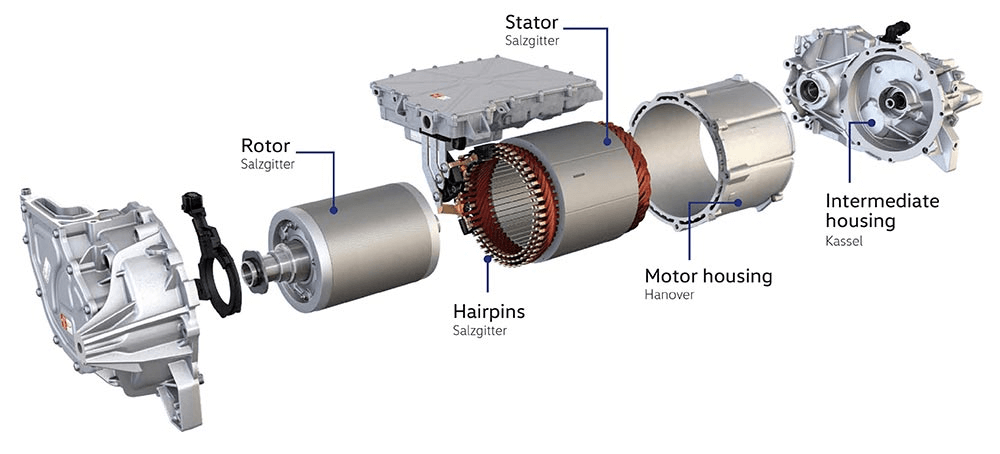

HONEST Intelligent Equipments covers the field of automotive component assembly, including motors, electronic controls, and gearboxes. With the acceleration of the development of new energy vehicles and the intensification of industry competition, integration, economy, and layout flexibility have become the focus of development for related enterprises. Gradually, the "two in one" electric drive, which integrates an electric motor and a gearbox, was introduced, saving a lot of space for the front cabin of cars. Later, in order to further reduce volume and weight, many enterprises invested in the development of "three in one" products. Compared to the "two in one" approach, the "three in one" approach further simplifies the external wiring between components. In addition to achieving lightweight, space saving, and extending range, it also makes the layout of various vehicle systems more flexible.

Nowadays, traditional car companies are pushing towards the high-end market, and in the new energy vehicle market, brand advancement is a major tool for achieving market breakthroughs. New forces, on the other hand, opened up the high-end market with their first mover advantage and began to sink in search of popular models. In the process of accelerating the transition to electrification, traditional car companies actively layout high-end intelligent electric vehicles based on their advantages in vehicle manufacturing, supply chain, capital chain, and other aspects. The project of HONEST is dedicated to the R&D and customization of the two in one (motor+gearbox) assembly production line for new energy vehicles, in response to industry development trends and national calls, to help production enterprises solve the problems of difficult recruitment and lack of guaranteed product quality.

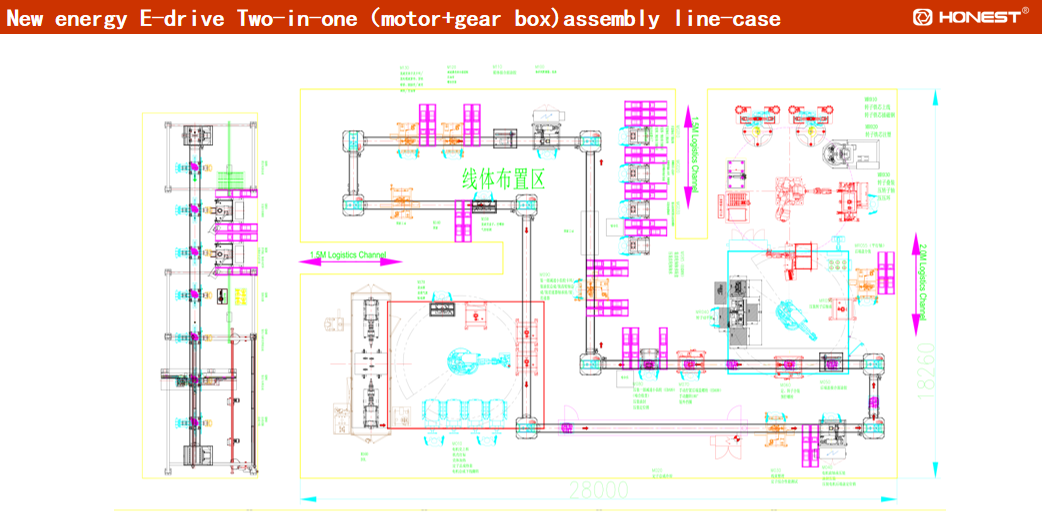

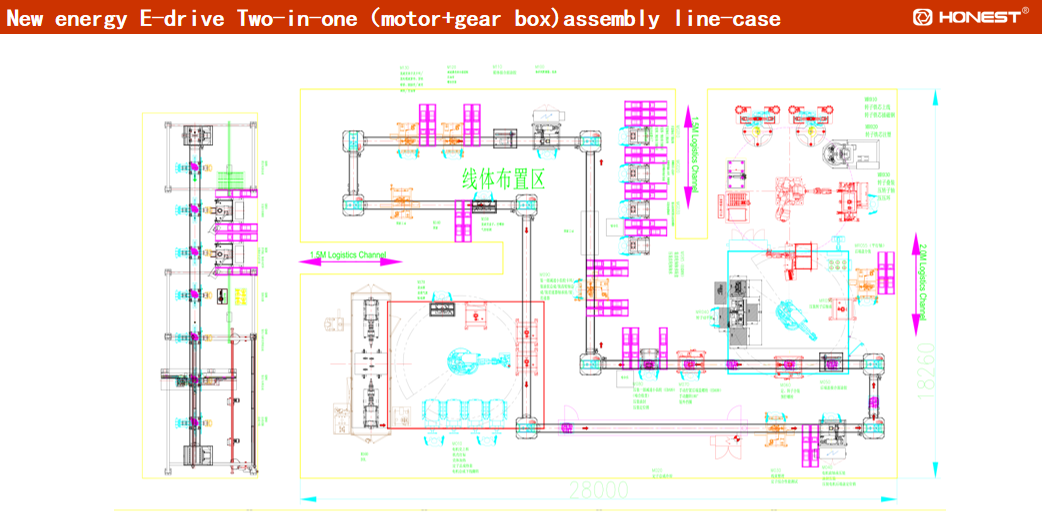

The automobile assembly production line of the 2-in-1 electric drive system of HONEST is compatible with the assembly and production of three products, with a replacement time of no more than 30 minutes, and the overall efficiency of the equipment can reach over 1 minute to produce a finished product. Configure multiple 6-axis robots for flexible production, with reasonable robot allocation to maximize the efficiency of robot use; Automatically connect between lines; Equipped with automated shafting meshing testing and shafting transfer equipment, with high accuracy and good reliability; Configure precision gluing equipment to ensure gluing quantity, gluing trajectory, and gluing width; Precision servo press ensures the precision of each pressing station, while monitoring the pressure change curve during the pressing process; Digitally manage production lines and bind process data.