Solving the Core Control Challenges in Motor Manufacturing

In the motor automation industry, electrical control systems are often the most complex and risk-sensitive part of a production line.

With increasing customization demands and shrinking delivery timelines, traditional PLC-based solutions are facing growing limitations.

Industry Challenges in Motor Automation

1. High Customization & Frequent Bugs

Motor production lines are typically non-standard automation systems. Each project differs in structure, process flow, and control logic.

Due to the high customization ratio, software development becomes complex, and bugs are difficult to eliminate.

2. Diverse PLC Brands & Programming Complexity

Customers often specify different PLC brands.

Different brands require different programming languages and software tools.

This creates:

Higher engineering workload

Increased risk of programming errors

Difficult cross-project standardization

3. Complex System Integration

Modern motor assembly lines integrate:

Multi-axis motion systems.

Servo motors.

Sensors.

Testing instruments.

Data acquisition systems.

These systems demand:

High precision.

High speed.

High stability.

This significantly raises the technical threshold.

4. Tight Delivery Schedule

Customers expect faster delivery in a competitive market.

However, complex electrical system design conflicts with short development cycles, resulting in:

Heavy debugging pressure

Resource constraints

Increased project risk

5. Difficult After-Sales Support

When unexpected issues occur onsite:

Program modifications may require remote access

Travel limitations slow response

Language barriers create communication gaps

This often affects customer satisfaction and equipment uptime.

6. Debugging & Talent Challenges

Highly integrated systems require strict logical control.

Debugging is complex.

Skilled multi-disciplinary engineers are rare.

Training cycles are long and labor costs are high.

Our Solution: HONEST Automation Universal Software Platform

To address these challenges, HONEST Automation has independently developed a Universal Software Platform specifically optimized for motor winding and motor assembly lines.

The platform has already been successfully applied in:

16 motor assembly lines.

3 motor winding machines.

186 pieces of equipment in total.

Including overseas motor production lines.

Key Advantages

1. Compact Yet Powerful Motion Control

One control unit supports multi-axis control.

Supports EtherCAT protocol.

High-speed data transmission.

Precise and synchronized motion control.

High-speed & high-accuracy performance.

2. Visual Programming – No PLC Software Required

No traditional PLC programming software required.

Visual programming interface.

Lower learning barrier.

Faster onboarding for operators and engineers.

Even non-specialized personnel can quickly understand and use the system.

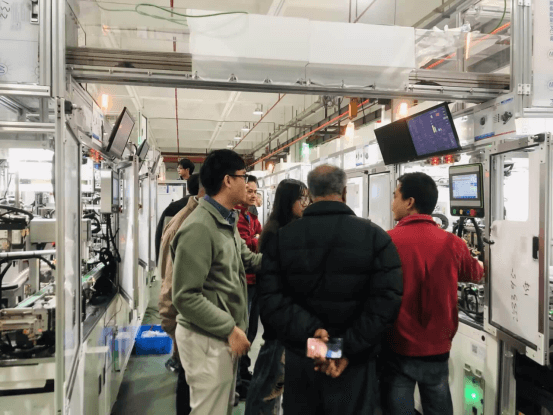

3. Faster On-Site Debugging

Programming and debugging can be performed directly against physical equipment.

Engineers can modify parameters or logic immediately on-site.

Faster issue resolution.

Reduced downtime.

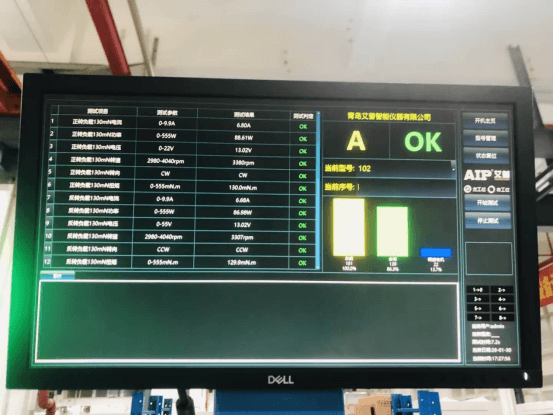

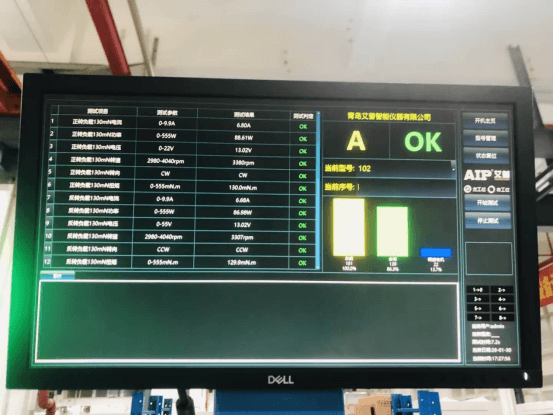

4. Real-Time Equipment Monitoring

Real-time production status monitoring.

Fast fault diagnosis guidance.

Improved machine utilization rate.

Enhanced OEE performance.

5. Shorter Delivery Time

Standardized software architecture reduces repetitive development work, enabling:

Faster project deployment.

Lower development risk.

More predictable delivery schedule.

6. Long-Term Platform Consistency

Customers benefit from:

Easier expansion for future projects.

Unified control architecture.

Reduced learning curve for new equipment.

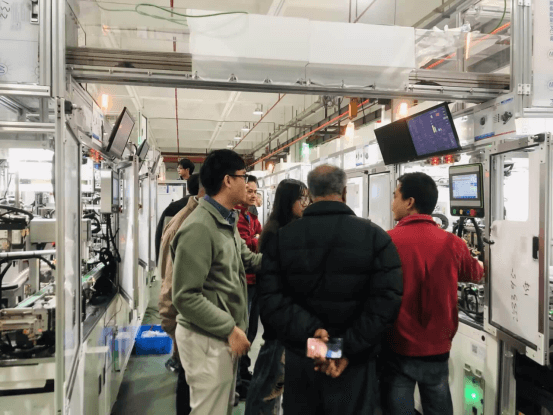

Proven in Real Motor Production Lines

Our Universal Software Platform represents a leading level of domestic control technology and is deeply integrated with motor automation equipment.

It performs especially well in:

Automotive motors

Humanoid robot motors

Power tool motors

Medical equipment motors

Let's Solve Your Control Challenges

If you need motor prototyping, motor stator and rotor winding, motor mass production, or a new factory to increase motor production,

We welcome you to contact us or visit our factory for a technical exchange.

HONEST Automation is committed to delivering more stable, efficient, and intelligent motor production solutions.