-

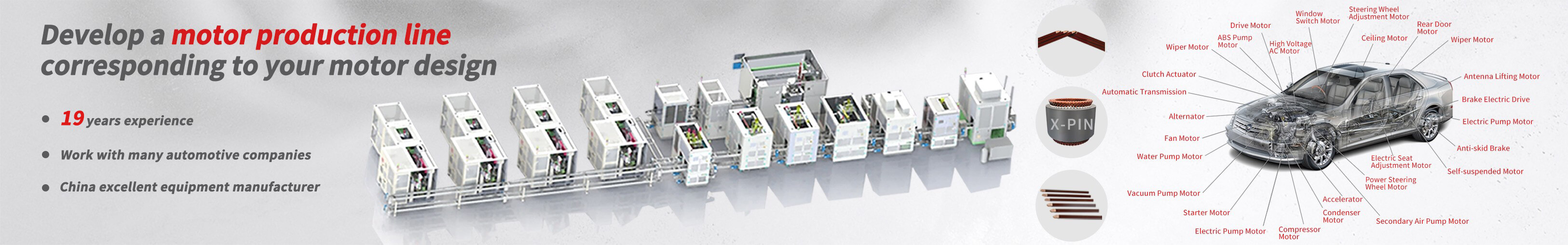

- EV Motor Manufacturing Assembly Line

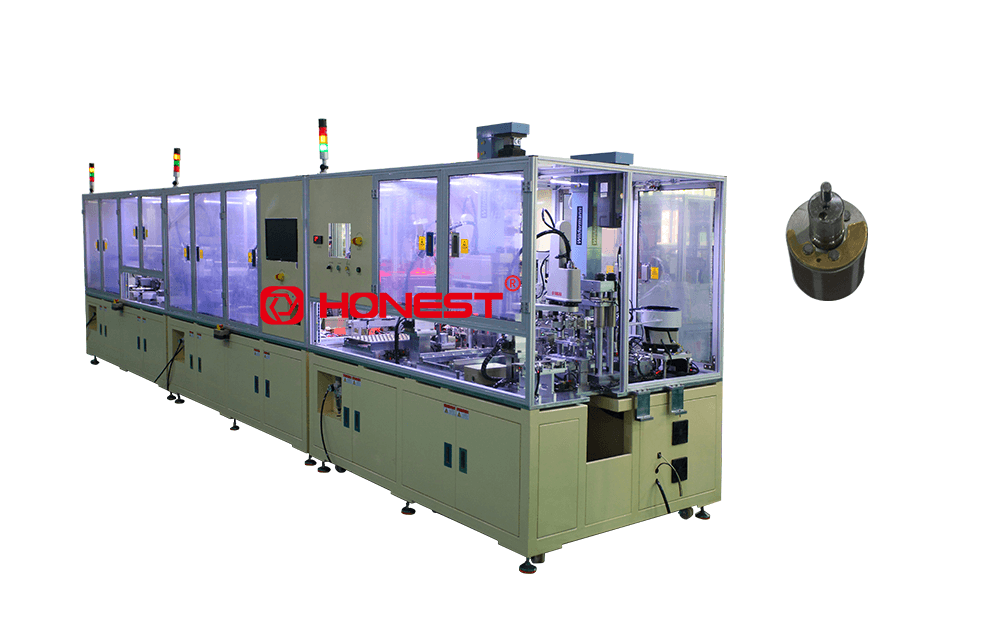

- BLDC Motor Assembly Line

- Stator Assembly Line

- Rotor Magnet Inserting Machine

- Brush Motor Assembly Line

- Inductor Winding Machine

- Motor Winding Machine

- Non-Cutting Hairpin Stator Twisting Machine

- Drive Motor Stator Production Line

- Hairpin Stator Assembly Line

- X-pin Motor Stator Production Line

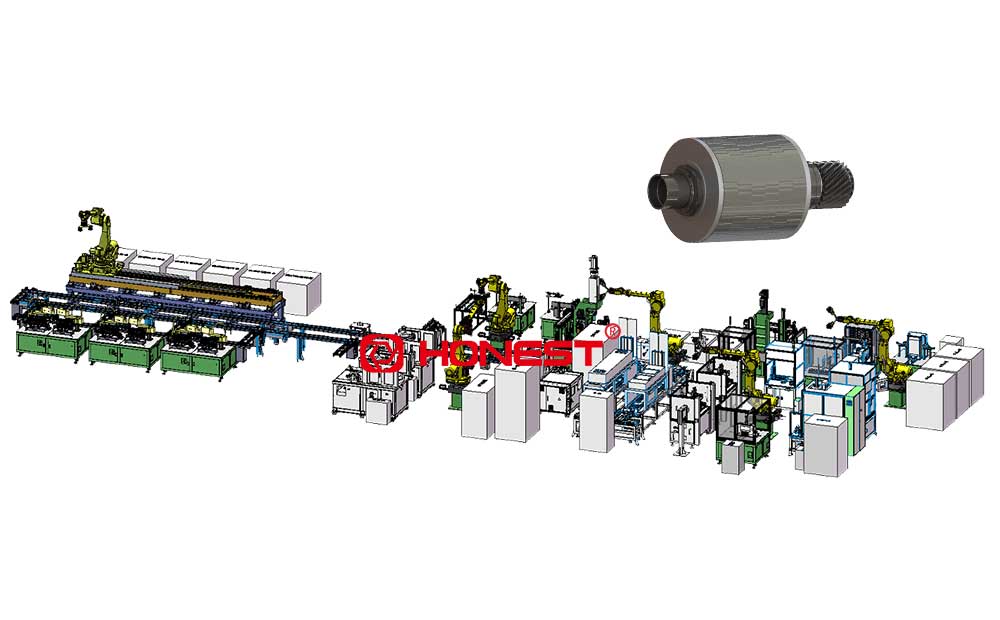

- Drive Traction Motor Assembly Line

- Hairpin Motor Stator Winding & Assembly Line

- Hairpin Motor Automatic Production Line

- Automobile Generator 48V BSG Motor Stator Assembly Line

- Humanoid Robot Motor Production Line

- Condenser Fan Motor Assembly Line

- Automotive EPS Motor Production Line

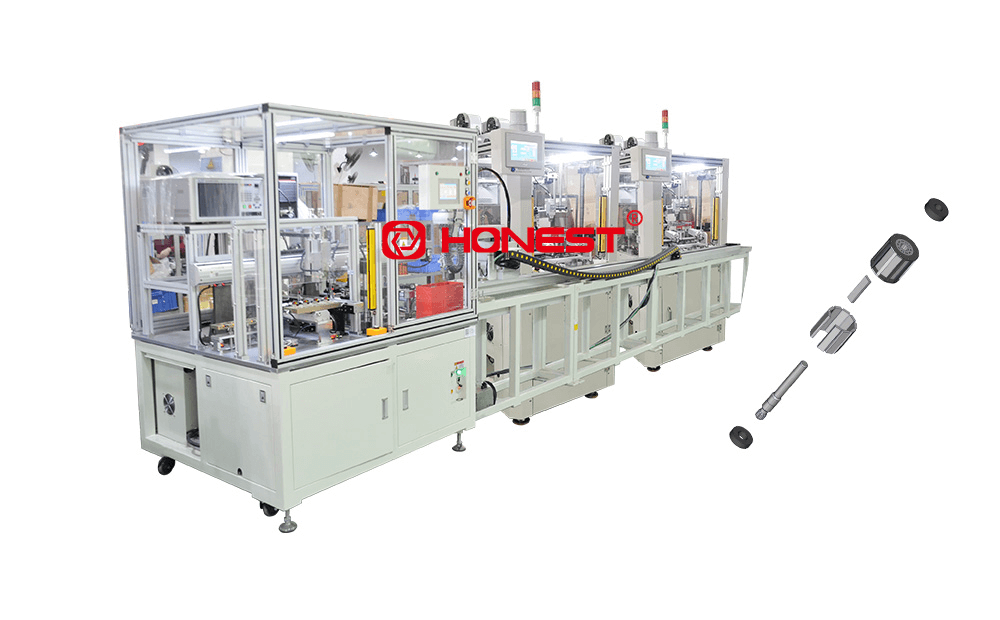

- Urea Pump Motor Assembly Line

- Electronic Oil Pump Motor Assembly Line

- Automotive EPS Motor Assembly Line

- Automotive Electronic Oil Pump Production Line

- EHPS System Motor Assembly Line

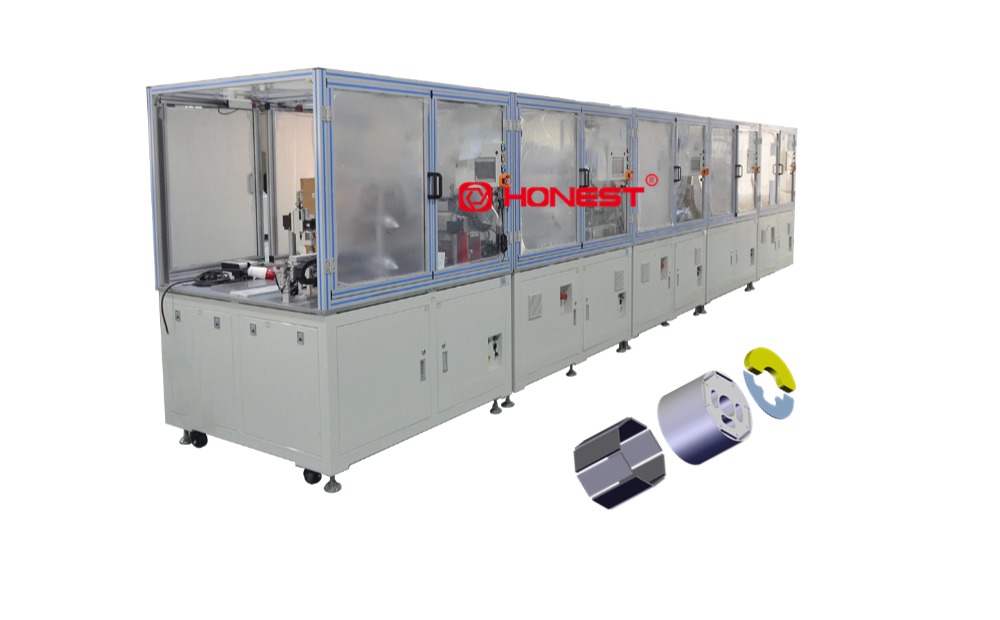

- Segmented Stator Production Line

- Automobile SBW Motor Stator Assembly Line

- Automotive Compressor Motor Assembly Line

- Commercial Vehicle Water Pump Stator Assembly Line

- EPS Motor Stator Production Line

- Split Motor Compressor Stator Assembly Line

- Automobile Air Pump Brushless Motor Stator Production Line

- Automotive Water Pump Brushless Motor Stator Assembly Line

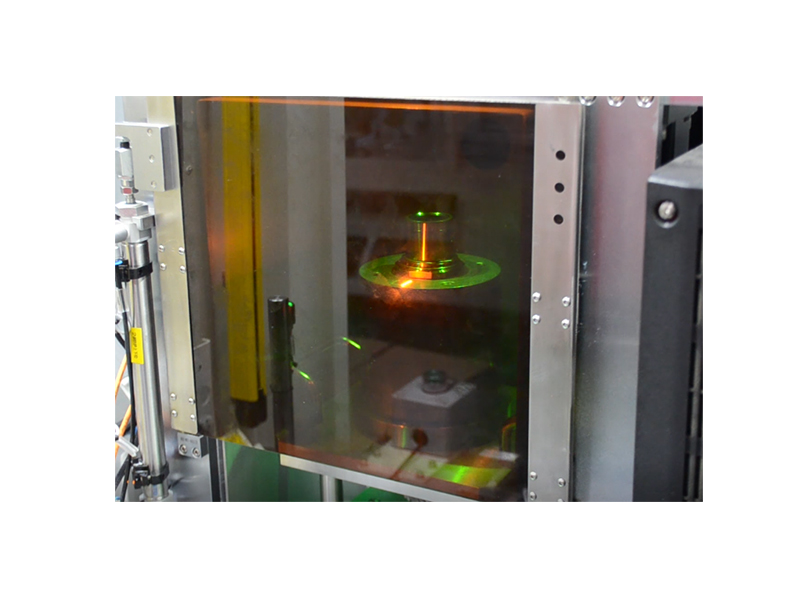

- Rotor Magnet Insert Magnetization Equipment

- BLDC Rotor Magnet Insertion Assembly Line

- Motor Rotor Magnet Insertion Machine

- Rotor Magnet Assembly Machine

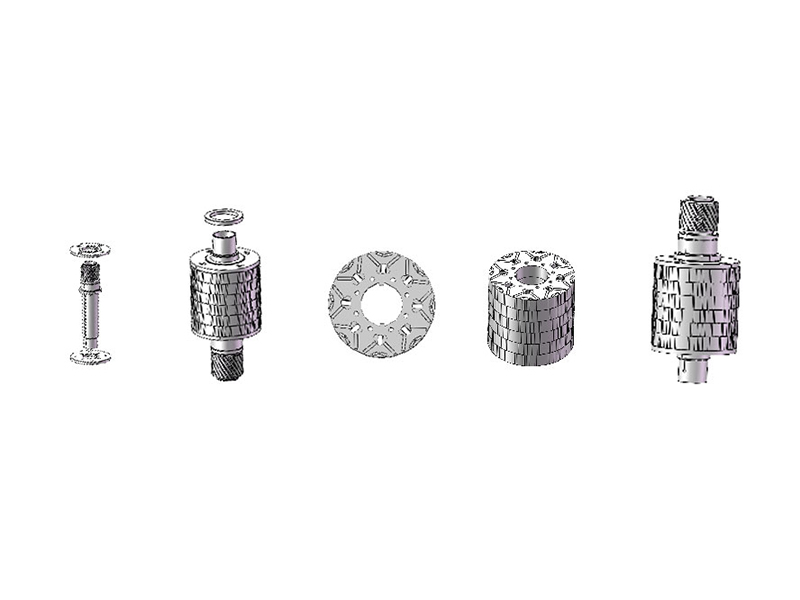

- Brushless Motor Rotor Assembly Line

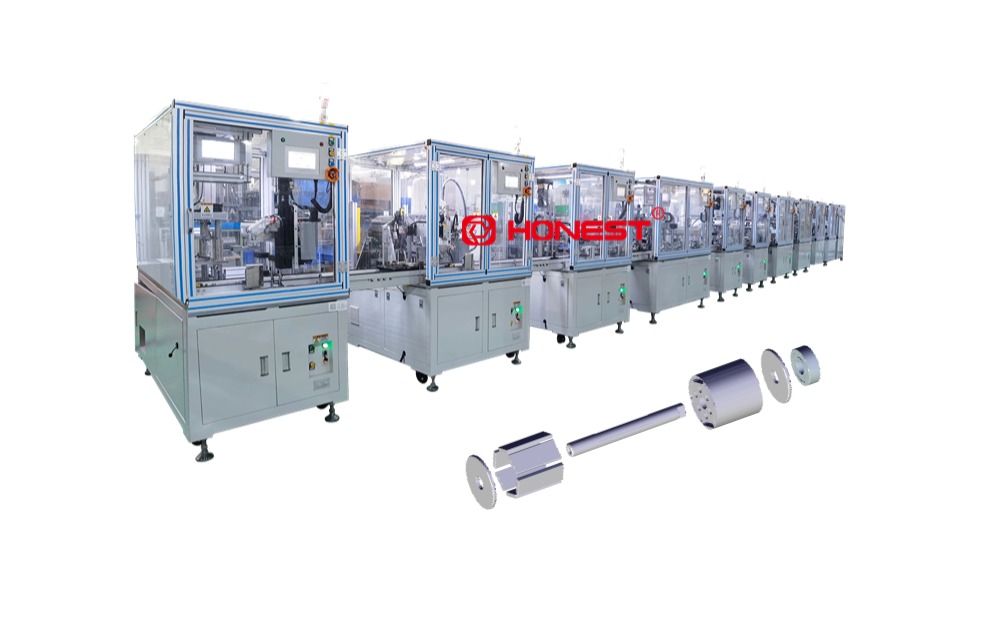

- Drive Motor Rotor Production Line

- Electric Vehicle Motor Rotor Assembly Line

- Automotive Air Suspension Motor Production Line

- Automotive Seat Motor Production Line

- Automobile Electric Sunroof Motor Assembly Line

- Automobile Water Pump Motor Assembly Line

- Automobile Power Tailgate Motor Assembly Line

- Air Conditioning Motor Assembly Line

- Automobile Door Lock Motor Assembly Line

- Power Window Motor Production Line

- Network Transformer Automatic Winding Machine

- Common Mode Inductor Winding Equipment

- Tcore Integrated Inductor Winding Machine

- NR SMD Inductor Fully Automatic Winding Machine

- Common Mode Choke Four-Axis Winding Machine

- NR Inductor Dispensing Machine

- Inductor SMD Test Packaging Machine

- Wheel Hub Motor Winding Machine

- Automatic Flyer Armature Winding Machine

- Air Conditioning Compressor Motor Winding Machine

- Stator Heating Assembly Winding Equipment

- EPS Motor Segmented Stator Winding Machine

- Hub Motor Stator Winding Machine

- Stator High Precision Wire Winding Machine

- Dual Station Segmented Stator Winding Machine