Case Study: Multiple Automotive Motor Assembly Lines Delivered in Ongoing Collaboration with the Customer

Customer Profile

The customer is a global leading industrial technology company, specializing in the development and manufacturing of drive products, control systems, and motion subsystems. It has operations and manufacturing facilities in over 20 countries and regions. Its core business includes micro motors, actuators, and motion systems, with applications across automotive, industrial, home appliances, medical devices, and humanoid robotics.

In the automotive sector, the customer provides customized drive motors, actuators, and system solutions for OEMs and Tier‑1 suppliers, with products applied in Electric Power Steering (EPS), chassis control, electric closure devices, and other key automotive components. The company also possesses advanced technologies and solutions in high-precision motion control for robotic joint motors.

Project Background & Challenges

The customer had new projects requiring automated production equipment to increase output and improve production efficiency. Their existing production lines were unable to meet the required capacity, especially in winding and welding processes.

Although the customer had worked with other motor automation equipment suppliers, they faced challenges, including equipment stability, delayed response from after-sales support, and the inability of existing systems to consistently meet production standards. The customer needed a partner capable of responding quickly to issues on-site, with experienced technicians who could troubleshoot and ensure stable operation without impacting production schedules.

Solution Provided by Honest Automation

Honest Automation provided over 20 automated production lines and standalone machines tailored to the customer’s diverse motor production needs. These included lines for motor end caps, oil pump motor rotors, trunk motors, dual-flyer rotor winding, water pump motors, sunroof motors, automotive door lock motors, and electric tool motors.

Our solutions focused on achieving high efficiency, stable operation, and traceable production data while reducing manual intervention. The systems were designed to be modular and scalable to accommodate future upgrades.

Key Equipment Features

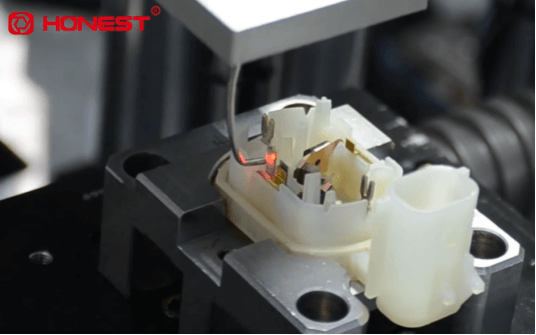

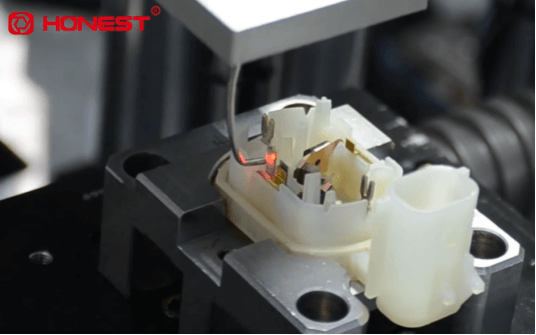

One example of the equipment delivered is the Oil Pump Motor Assembly Line, which demonstrates the approach and standards applied across all our equipment:

Application: Automotive oil pump motor rotor production.

Configuration: A linear layout of multiple automated machines integrated with conveyor systems, PLC+HMI control, and traceable data collection.

Advantages:

High production efficiency (CT=16s, TT=20s) and reliable quality (yield ≥98%, Utilization rate ≥90%).

Error-proofing and traceability, including scanning, data collection, and MES system integration.

Minimal labor required: key processes need only 1–2 operators.

Modular and flexible design, suitable for multiple motor types and future expansion.

Other production lines for different motor types share similar features, emphasizing stable operation, automation, and traceable quality, while maintaining ease of maintenance and user-friendly operation.

Performance & Results

Production efficiency improved significantly, meeting the customer’s capacity targets.

High product quality and traceability are ensured, reducing defects and errors.

The automated lines required minimal operator intervention, lowering labor dependency and operational risk.

The modular design allows rapid changeovers between different motor types and supports future upgrades.

Why Honest Automation

The customer chose Honest Automation for several reasons:

Technical Leadership: Our expertise in stator and rotor winding allows us to solve complex issues such as winding, rotor assembly, and welding with high reliability.

Stable and Responsive Equipment: Our machines operate consistently, and our large, experienced after-sales team responds quickly to any production issues.

Dedicated Project Team: Key technical personnel remained consistent throughout the project, ensuring smooth communication and avoiding delays caused by frequent staff changes.

Commitment and Responsibility: We take full responsibility for our equipment. Even when facing difficult problems, our technicians have worked onsite late into the night to resolve issues, ensuring no project is left incomplete. We provide timely support for upgrades and modifications as needed.

Application & Scalability

Honest Automation has provided the customer with multiple specialized production lines tailored to different automotive motor types, including EPS motors, water pump motors, sunroof motors, oil pump motors, door lock motors, and more. The repeated collaboration reflects the customer’s trust in our ability to deliver high-quality equipment and reliable service. Each production line is designed for stability, efficiency, and traceable quality, and our modular approach allows for future upgrades and expansion as the customer’s production needs evolve.