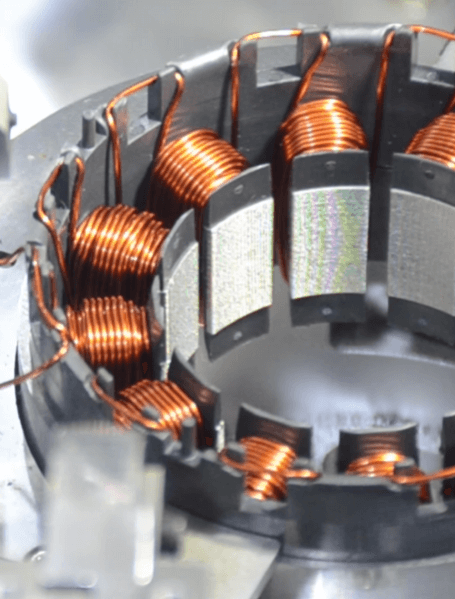

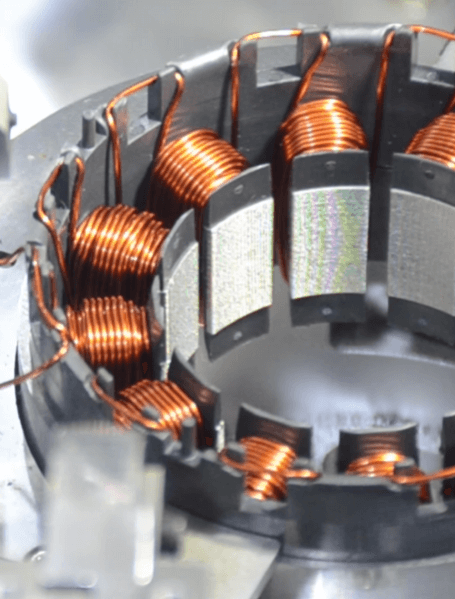

Case Study: Commercial Vehicle Water Pump Motor Stator Assembly Line Delivered to a Customer Factory

Customer Profile

The customer is a group company headquartered in Michigan, USA, specializing in the development, manufacturing, and service of rotating electrical products for heavy-duty vehicles, with a strong international presence in the industry. The company operates a central R&D base in the United States, manufacturing facilities across North America, Europe, and China, and distribution centers in the U.S., Mexico, and Brazil.

Its core products, including alternators and starters, are widely applied in buses, light-, medium-, and heavy-duty trucks, construction machinery, diesel engines, as well as marine and generator set applications.

Project Background & Challenges

As reliability and durability requirements in the commercial vehicle market continue to rise, the customer sought to introduce automated equipment in a new project to increase production capacity and process consistency, meeting the demands of high-volume water pump stator manufacturing.

The core challenges of the project were concentrated in the post-winding segment stator round-forming and welding processes. These operations impose stringent requirements on welding consistency, structural integrity, and the pass rate of subsequent air-leak (airtightness) testing, making them one of the most critical and technically demanding stages of the entire production process. In addition, the customer maintains strict quality standards for product yield and long-term operational stability.

Solution Provided by Honest Automation

In response to the customer’s requirements, Honest Automation delivered an automated segment stator production solution for this project, covering key manufacturing processes including winding, round-forming and welding, assembly, and performance testing.

The entire production line is designed with a modular architecture, in which multiple functional stations operate collaboratively to complete the manufacturing process. An integrated industrial control system enables centralized production data management and full traceability. While ensuring stable and reliable process performance, the solution also provides the flexibility required for future product variants and production line upgrades.

Key Equipment Features

Stable and reliable segment stator winding and round-forming solution

The equipment is specifically optimized for the structural characteristics of segment stators, ensuring stable and consistent winding and round-forming processes. This provides a solid and reliable foundation for subsequent welding quality.

High-consistency welding and inspection assurance

By integrating multi-dimensional monitoring and inspection systems, critical processes are continuously controlled and verified, effectively ensuring product consistency and airtightness performance.

Comprehensive poka-yoke and safety design

Multiple sensor-based monitoring systems, program interlocks, and alarm mechanisms are implemented throughout the entire production process, minimizing the risk of human error and significantly enhancing operational safety.

Modular and flexible design

The production line features a compact layout and supports multiple product specifications. Rapid changeover can be achieved through system-based switching, reducing adjustment time and improving overall production flexibility.

Performance & Results

Production cycle time meets the customer’s planned capacity requirements.

Product yield remains consistently above 99%.

Overall line utilization exceeds 90%.

Production process data is fully traceable, facilitating quality analysis and continuous improvement.

After project delivery, the production line operates stably and successfully passes the customer’s internal quality verification, providing a reliable foundation for subsequent mass production.

Why Honest Automation

The customer ultimately chose Honest Automation based on the following factors:

Mature technical expertise in segment stator winding, round-forming, and welding processes.

Stable equipment performance, capable of meeting high consistency and quality requirements.

A core technical team with long-term experience in motor manufacturing and automation equipment, possessing extensive hands-on project expertise.

Provision of comprehensive process support for the customer’s products; the customer base primarily includes leading multinational companies and renowned brands, representing advanced market-level technologies.

Proven technology and successful project track record in the market, minimizing the risk of failure.

Application & Scalability

This solution is suitable for applications such as commercial vehicle water pump stators, where high reliability and sealing performance are critical. Thanks to its modular and standardized design, the production line offers excellent replicability and can be quickly adapted to different power ratings and product specifications, supporting the customer’s ongoing expansion and capacity upgrades in future projects.

After successfully delivering our equipment to the customer’s factory in China and achieving stable production with full customer approval, we were granted the opportunity to become one of the approved suppliers for their U.S. headquarters.