The clutch actuator is a key component in the transmission of a vehicle, primarily responsible for controlling the engagement and disengagement of the clutch. In automatic and semi-automatic transmissions, the clutch actuator is usually motor-driven and operates the clutch via a hydraulic system or electronic signals to achieve smooth gear shifts and vehicle starts.

1. The Role of Clutch Actuator in the Transmission of Automobiles

Control of Clutch Engagement and Disengagement: The main function of the clutch actuator is to control the engagement and disengagement of the clutch, allowing or interrupting the power transmission between the engine and the transmission.

Smooth Gear Shifts: In automatic or semi-automatic transmissions, the clutch actuator helps achieve smooth gear shifts by precisely controlling the engagement and disengagement of the clutch, reducing shocks and jerks during driving.

Transmission of Engine Torque: In dual-clutch transmissions, the clutch actuator controls different clutches to transmit the engine's torque to different output shafts, driving different gears.

Improved Driving Comfort: By precisely controlling the engagement of the clutch, the clutch actuator contributes to improved driving comfort, especially in urban driving and frequent stop-start traffic conditions.

Support for Start and Stop: At vehicle start, the clutch actuator controls the gradual engagement of the clutch to prevent stalling or vehicle shuddering due to sudden engagement. When parking, it controls the disengagement of the clutch to interrupt power transmission.

Coordination with Transmission Control Unit (TCU): The clutch actuator works closely with the TCU, receiving instructions from the TCU based on driving conditions and driver input to perform precise operations of the clutch.

Fault Diagnosis and Feedback: Some clutch actuators are equipped with sensors that provide feedback to the TCU regarding the position and status of the clutch, aiding in fault diagnosis and health management of the transmission.

Adaptation to Different Driving Modes: In some advanced transmission systems, the clutch actuator can adjust its working characteristics according to different driving modes (such as sport mode, economy mode, and so on.) to suit the driver's driving style.

Improved Fuel Efficiency: By precisely controlling the engagement and disengagement of the clutch, the clutch actuator helps improve the vehicle's fuel efficiency, especially in city driving with frequent gear shifts.

Enhanced Driving Safety: In emergencies where rapid gear shifting or interruption of power transmission is required, the clutch actuator can respond quickly, thus enhancing driving safety.

Crucial Functions: These functions of the clutch actuator are crucial for the transmission efficiency, driving experience, and overall performance of the vehicle.

2. Working Principle of the Clutch Actuator

Clutch actuators typically operate using either an electric motor drive or a hydraulic drive, with different designs leading to different working principles.

A. Electric Motor-Driven Clutch Actuator

a. Control Signal: When the Transmission Control Unit (TCU) issues a gear shift command, it sends an electronic signal to the clutch actuator.

b. Motor Rotation: Upon receiving the signal, the internal motor of the actuator starts to rotate.

c. Gear Mechanism: The motor uses a gear mechanism to convert rotary motion into linear motion.

d. Operation of the Actuating Rod: The linear motion is transmitted through an actuating rod or lever system to push or pull the clutch fork.

e. Clutch Engagement or Disengagement: The action of the actuating rod allows the clutch disc to engage or disengage from the engine's flywheel, controlling the transmission of power.

B. Hydraulically Driven Clutch Actuator

a. Control Signal: Similarly, the TCU issues a gear shift command that is conveyed to the hydraulic actuator.

b. Solenoid Valve Control: The solenoid valve in the actuator receives the electronic signal and controls the flow of hydraulic fluid.

c. Hydraulic Cylinder Action: Hydraulic fluid flows into the hydraulic cylinder, pushing the internal piston.

d. Piston Linear Motion: The movement of the piston is linear, either directly or through a lever system, pushing the clutch actuating rod.

e. Clutch Operation: Similar to the motor-driven actuator, the action of the actuating rod results in the engagement or disengagement of the clutch disc from the flywheel.

3. Key Components and Design Considerations of the Clutch Actuator

Key Components:

Motor: The motor-driven actuator uses a motor to generate power. The selection of the motor needs to consider its torque characteristics, efficiency, and response speed.

Gear Mechanism: The gear mechanism converts the motor's rotary motion into linear motion, and the design must consider the strength and wear resistance of the gears.

Hydraulic Cylinder: In a hydraulically driven system, the hydraulic cylinder is the core component, and its design must ensure sufficient force and precise control.

Solenoid Valve: Controls the flow of hydraulic fluid to achieve rapid response and precise control.

Sensors: Used to monitor the position, speed, pressure, etc., of the actuator, providing feedback signals to the control unit.

Control Unit: Receives sensor signals and instructions from the transmission control unit to control the operation of the motor or solenoid valve.

Actuating Rod: Connected to the actuator, it directly pushes or pulls the clutch fork to achieve the engagement and disengagement of the clutch.

Housing: It protects internal components while providing structural support, requiring sufficient strength and sealing.

Lines and Connections: In hydraulic systems, it is used to connect the hydraulic cylinder and solenoid valve, ensuring sealing and corrosion resistance.

Design Considerations:

Response Speed: It is a primary consideration for the clutch actuator, with rapid response to control signals to achieve quick gear shifts.

Precise Control: The design must ensure that the clutch actuator can precisely control the operation of the clutch to enhance the smoothness of gear shifts.

Durability: As a high-load component in vehicles, the clutch actuator's design should consider its long-term reliability and durability.

Maintenance Convenience and Cost-Effectiveness: To save costs, the design should consider the convenience and cost of maintenance and replacement while meeting performance requirements.

Integration: Modern vehicles tend towards high integration, and the design of the clutch actuator should consider adapting to limited space, requiring a more compact design.

Compatibility: The clutch actuator should be compatible with different models of transmissions to meet the needs of different vehicle models.

Safety: The design should focus on safety performance, ensuring normal operation under various conditions and avoiding safety issues due to its failure.

Environmental Adaptability: Due to the richness of vehicle usage scenarios, the clutch actuator should also be able to adapt to various environments and work normally under various humidity and temperature conditions.

Diagnostic Functions: The design can consider integrating diagnostic functions to facilitate fault detection and repair.

4. The future development trends of clutch actuators

Electrification and Hybrid: With the rise of hybrid and electric vehicles, clutch actuators will need to be designed to work efficiently with electric motors and energy recovery systems.

Increased Precision and Responsiveness: The advancements in control algorithms and sensor technology will lead to clutch actuators with higher precision and faster response times, enhancing the driving experience.

Energy Efficiency: It will focus on designing energy-efficient clutch actuators that consume less power, contributing to the overall energy efficiency of the vehicle.

Durability and Longevity: With vehicles becoming more and more complex, there will be a greater emphasis on the durability and longevity of clutch actuators to ensure they can withstand the rigors of long-term use.

Environmentally Friendly: In response to environmental-protecting policies, there will be a push towards using more environmentally friendly materials and manufacturing processes to reduce the ecological pollution of clutch actuators.

...

5. Why Choose HONEST Automation

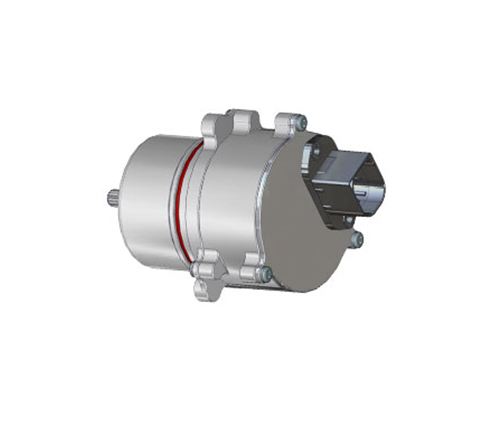

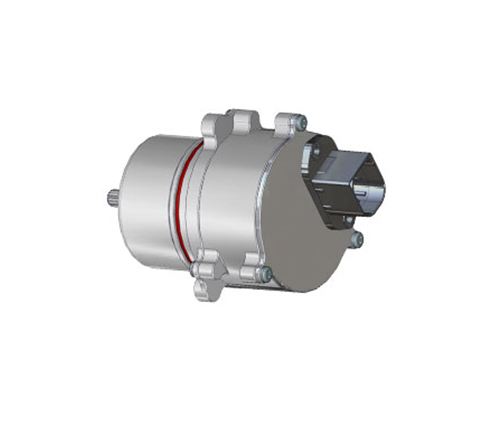

The picture shows our Automatic Assembly Line for Automobile Shift Motors, which can produce a product in less than 12 seconds and has the characteristics of high efficiency, matching, reliability, and safety.

As a leading motor winding machine manufacturer, HONEST Automation’s products satisfied a lot of customers, we won the Best Delivery Award, Quality Supplier Award, Outstanding Supplier Award, and Technical Breakthrough Supplier Award which were awarded by customers. And our products all passed the ISO09001 Quality Management System Certification.

If you have any requirements, don’t hesitate to contact us at your convenience.