Case Study: Humanoid Robot Joint Motor Frameless Stator Welding Machine

Customer Profile

The company is a Sino-German-Swiss joint venture specializing in the manufacturing of a full range of servo motors, frameless motors, joint modules, brushless motors, and stepper motors, as well as related drive systems.

Its products are widely applied in robotics, automotive, industrial automation, medical devices, intelligent logistics, telecommunications, and home appliances, and are exported to the United States, Germany, Switzerland, Italy, France, and many other countries and regions worldwide.

Project Background & Challenges

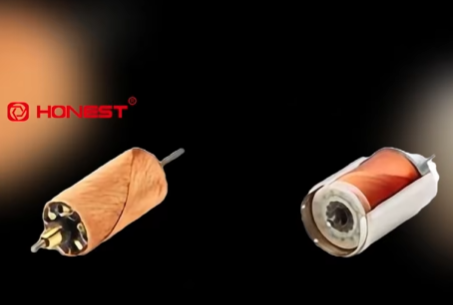

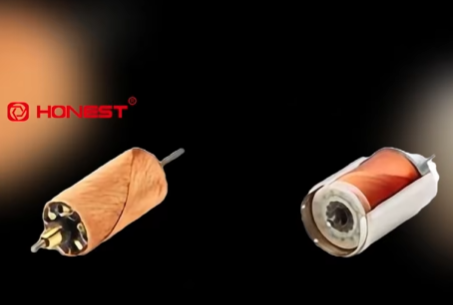

The client needed to mass-produce its frameless modular stator when developing a new humanoid robot articulated motor project. The project's challenges lie in the stator's small size and complex structure. During the welding process, it was crucial to ensure that the modular stator was assembled neatly, with uniform and defect-free welds. Furthermore, the welding precision directly affected the motor's performance and lifespan.

Solution Provided by Honest Automation

Honest Automation provides its customers with a frameless stator panel laser welding system. This semi-automated, modular design ensures compatibility with various product models. The system supports rapid program switching and fixture replacement, enabling efficient mass production. Precise laser welding technology and a servo drive mechanism ensure that each stator core panel is welded smoothly, with uniform and defect-free welds. Furthermore, the system is scalable and upgradeable to accommodate future production needs for more stator models.

Key Equipment Features

Each iron core is equipped with a floating pressure head to ensure the non-leading end of the core is flush.

The laser welding fixture is rationally designed to avoid laser damage caused by hitting the fixture.

Dual-path symmetrical pulse welding disperses heat input through skip welding, reducing welding deformation.

The starting and ending points of the weld are 2-3 laminations away from the end face of the iron core, preventing weld penetration of the frame and enameled wire.

The laser welding gun angle can tilt up and down by 60 degrees and finely adjust left and right by 6mm, with graduation markings to ensure welding flexibility.

Equipped with a shift inspection function and a servo rotary indexing mechanism to achieve uniform circumferential welding.

Performance & Results

Personnel required: 1 operator can handle 2–3 machines

Changeover time: 2 hours (including winding tooling, pressing head, and winding parameters)

Compatible wire diameter: 0.3–1.0 mm

Slot fill rate: 75%–85%

Wire placement accuracy: ±0.05 mm

Workstations: Three-station winding

Yield rate: ≥99%

Utilization rate: ≥90%

Why Honest Automation

The main reasons customers choose Honest Automation:

We possess mature, market-proven, and low-risk frameless stator welding technology.

Our core technical team is highly experienced and stable, capable of providing professional equipment design and process support.

Our strong after-sales service team can provide timely remote online support or rapid on-site problem-solving.

Our semi-automated equipment design balances production efficiency and flexibility, meeting diverse customer needs.

Application & Scalability

This equipment is suitable for the frameless modular stator production of articulated motors for humanoid robots. Its modular design allows for rapid compatibility with various stator models. The equipment is compact, durable, and provides stable operation for long-term use. In the future, if customers need to expand production capacity, accommodate more models, or upgrade, Honest Automation's technical team can provide timely and targeted solutions, avoiding the need for customers to repeatedly purchase new equipment and reducing long-term operating and maintenance costs.

In addition to this laser welding equipment, we also provided the client with a frameless motor assembly line and a robot joint stator winding machine, among other related equipment.