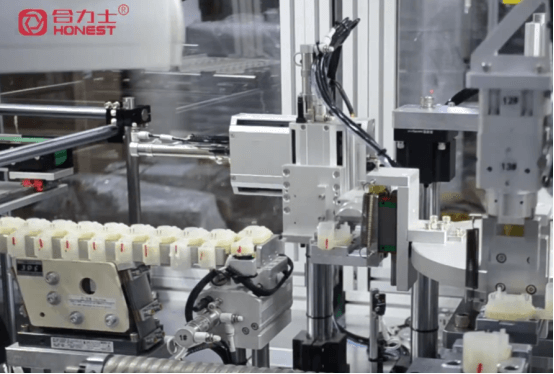

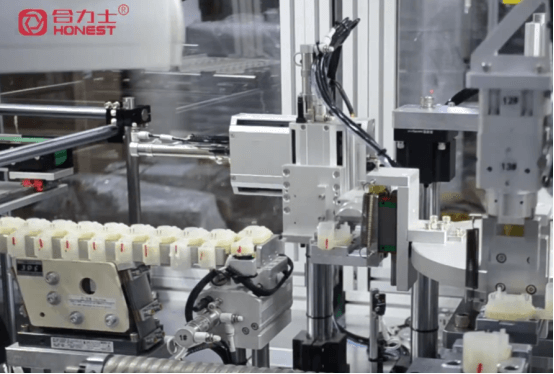

Case Study: Motor End Cap Assembly Line Delivered to the Customer's Factory

Customer Profile

This company specializes in motors for automotive power windows, including sliding door motors, window regulator motors, and tailgate motors. It holds over 30% market share in China and is actively expanding into overseas markets. Its customers are located worldwide, including Volkswagen, Volvo, Buick, BYD, GAC Group, SAIC Motor, Changan Automobile, and Geely Automobile.

Project Background & Challenges

The project focuses on the automated assembly of motor end caps, which are mainly used in automotive window lift motors and sunroof motors. With increasing order volumes, the customer aimed to achieve stable mass production, higher efficiency, and consistent product quality through automation.

The main challenge lies in the high complexity and tight tolerance requirements of the end-cap precision assembly process. Key difficulties include:

Precise insertion of brush arms

Terminal cutting and forming

Clip welding of thermal protectors and varistors

Multiple assembly and welding processes require post-assembly quality verification

These processes place high demands on assembly accuracy, welding stability, inspection reliability, and error-proofing capability, making manual or semi-automatic production insufficient for long-term, high-quality mass production.

Solution Provided by Honest Automation

Honest Automation delivered a customized motor end-cap assembly automation line, providing a one-stop solution covering component feeding, assembly, welding, and inspection.

The production line integrates multiple automated stations and advanced process controls, including visual inspection, displacement and depth detection, pressure monitoring, welding inspection, and comprehensive poka-yoke mechanisms. From the design stage, the line also reserves space and interfaces for future product upgrades and capacity expansion, ensuring long-term adaptability.

Key Equipment Features

Multi-Level Inspection and Error-Proofing

Equipped with high-precision sensors and vision systems to prevent missing, incorrect, or insufficient assembly, with post-assembly quality inspection.

Stable Execution of Complex Processes

Dedicated mechanisms and optimized control logic ensure reliable performance for challenging operations such as brush arm insertion, terminal cutting, and clip welding.

Ergonomic and Safety-Oriented Design

User-friendly operation with safety door locks, air pressure protection, and real-time fault alarms to ensure operator safety.

Fast Changeover Capability

Single-station changeover time of ≤10 minutes, enabling quick adaptation to different product variants.

Performance & Results

Production cycle time: ≤3 seconds per piece

Yield rate: ≥98%

Overall line utilization rate: ≥90%

Operator requirement: 1 person (component preparation)

Long-term stable operation in the customer’s factory

High product consistency, significantly reducing rework and quality risks

The line has been successfully running in mass production, effectively supporting the customer’s delivery schedules.

Why Honest Automation

Proven track record with multiple successful motor end-cap assembly projects

After the first line was delivered and operated stably, the customer repurchased several similar lines to support capacity expansion

Strong non-standard customization capability, meeting required output targets within the agreed timeline

Consistent product quality and stable operation, helping the customer fulfill delivery commitments to OEM clients

Reliable equipment performance, reducing long-term operational risks

Application & Scalability

Honest Automation’s motor end cap assembly line demonstrates excellent scalability and replicability. This customer has placed multiple orders for identical production lines, reflecting their strong trust in the performance, reliability, and quality of our equipment. New lines can be quickly deployed with minimal adjustments, while upgrades and expansions can be accommodated within existing factory layouts, minimizing additional space requirements and investment. Our customized retrofit solutions further reduce the need for entirely new lines, lowering long-term ownership costs and enhancing operational flexibility.