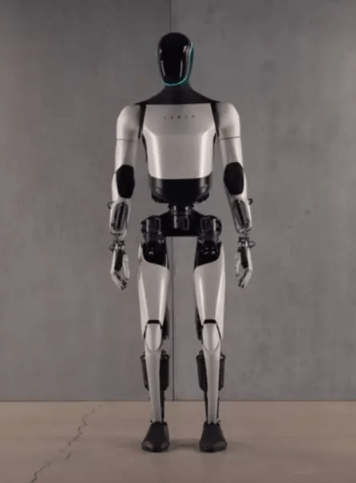

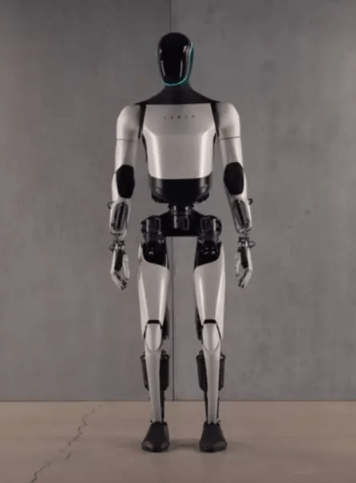

Tesla unveiled its Optimus Gen 2 humanoid robot, which can walk 30 percent faster and has improved balance and body control.

According to the current design of Tesla humanoid robots, 28 frameless motors are required for all joints of the body. If 1 million Tesla humanoid robots are produced, there will be a demand for 28 million frameless motors. Compared with collaborative robots, the demand for frameless motor for humanoid robots may be magnified 28 times. The launch of Tesla's new humanoid robot is expected to bring a broad market space for the frameless motor market.

Frameless Torque Motor Industry Overview

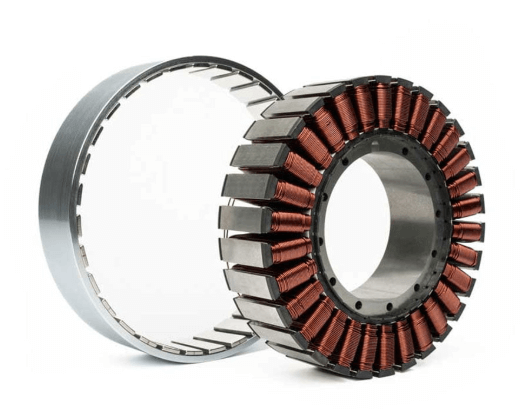

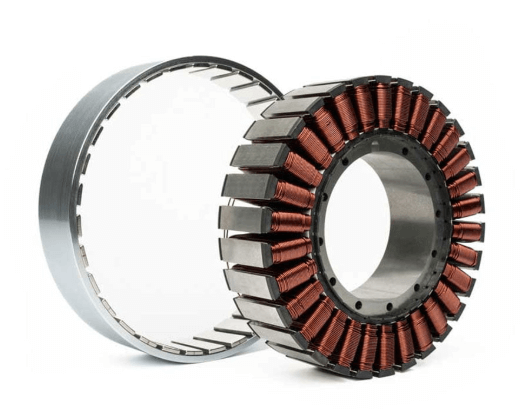

Torque motor are unique brushless permanent magnet synchronous motors that are characterized by the load being directly connected to the rotor without any transmission components, which classifies them as direct drive motors.

Similar to linear motor, torque motor are also "frameless" motors, meaning they have no shaft, bearings, housing, feedback, or end caps, and consist only of a stator and a rotor, where the rotor has a hollow structure to facilitate internal wiring of the joint.

Frameless torque motor were first invented in 1949 by the Inland Motor Company of the United States (which merged with Kollmorgen Optics in 1960 to form Kollmorgen), and were primarily used in transmission universal joints in inertial guidance systems for missiles and space vehicles in the early days.

Today, the application range of frameless motors has been greatly expanded, including robots and robot joints, universal joints for sensors, aiming systems, drone propulsion and navigation, and factory automation equipment.

Due to the high efficiency, small size, and high torque per unit volume of frameless motors, they are particularly suitable for rotary joint applications in humanoid robots.

Frameless motor are usually combined with other components to form robot joint modules:

As a power source, frameless torque motor are similar in function to traditional servo motors, but they show significant advantages in specific applications. Frameless motor are more customizable than standard products such as servo motors.

Frameless torque motor belong to the category of low-voltage servo motors, and their operating voltage can meet the needs of humanoid robots, so a 48v motor system can be used throughout the body.

Compared with high-voltage servos, low-voltage servos can achieve higher performance. Many low-voltage servo systems use Mosfet technology, which has a higher switching frequency and better drive performance.

Frameless torque motor have the ability to run at low speeds for a long time (even shut down), while servo motors mainly rely on pulses for positioning and form an automatic control system so that the output control quantity can be adjusted arbitrarily as the input target (or given value) changes.

Frameless Torque Motor have Obvious Advantages Over Servo Motor:

|

Motor Features

|

Frameless Torque Motor

|

Servo Motor

|

|

Motor Principle

|

Allows frameless torque motor to run at low speed for long periods of time (even stopped), with higher temperatures, usually requiring cooling by external blowers

|

An automatic control system that allows the output control quantity, such as the corresponding position, direction, state, etc., to change arbitrarily with the input target (or given value). It mainly relies on pulse positioning. Once a pulse is received, it will rotate to an angle that matches the pulse to move.

|

|

Motor Performance

|

A special motor with a large amount of polarization that allows it to continue running at low speeds without damaging the motor even when the motor is locked (the rotor cannot turn). In this operating mode, the motor can provide a stable torque to the load.

|

The speed and position can be precisely controlled, and the voltage signal is converted into torque and speed for driving. The rotor speed is controlled by the input signal and has a sensitive response. The actuator of the automatic control system has the characteristics of small electromechanical time constant, high linearity and high starting voltage.

|

|

Stiffness

|

Extremely high stiffness, no belts, pulleys, screws or gearboxes required to directly drive the load.

|

It is positively correlated with the response speed, but adjusting it too high can easily cause mechanical resonance.

|

|

Efficiency

|

Directly integrated into the structure of the machine, reducing wind friction losses and thus high efficiency.

|

Higher, usually up to 90%.

|

|

Noise

|

Directly integrated into the structure of the machine, it changes the transmission mode (even without a reducer), bringing a significant quiet effect.

|

There are many mechanical transmission structures, and the noise is obvious.

|

|

Stability & Maintainability

|

High stability and low maintenance. Since the frameless torque motor is directly integrated into the structure of the machine, the number of parts used is reduced, so the machine is easier to work stably.

|

It runs smoothly at low speed but tends to fluctuate at high speed, and its accuracy is average.

|

Frameless torque motor products are mainly used in robotics, medicine, aerospace, optics and other fields with high technical requirements.

At present, frameless torque motors have been used in some quadrupedal and bipedal robots, such as the Cheetah quadrupedal robot developed by the Massachusetts Institute of Technology MIT and the WALK-MAN bipedal robot funded and designed by the European Union.

In terms of technical barriers, frameless torque motors have technical barriers in magnetic circuits and process design. Magnetic circuit and process design have an important impact on the torque density and power density of the motor, and these two indicators are directly related to the performance of the robot. Since frameless torque motors need to output large power in a low-voltage power supply environment, there are certain technical requirements in magnetic circuits and process design.

From the perspective of the industrial chain, the upstream of frameless torque motors includes raw material supply such as steel, copper, aluminum, etc. Parts manufacturing includes stators, rotors, bearings, end covers, etc. Midstream motor manufacturing assembles and debugs parts to produce finished frameless torque motors. Downstream manufacturers sell frameless torque motors to distributors or end users, and distributors then sell the products to more customers. The industrial chain of frameless torque motors also includes R&D, design, quality control, etc.

Frameless Torque Motor Competition Landscape and Key Companies

In terms of market pattern, frameless torque motors have long been mainly supplied by foreign manufacturers, but in recent years, the localization process is being actively promoted.

Globally, the leading manufacturers in the frameless torque motor market include Kollmorgen, TQ-RoboDrive, Aerctech, Parher, Allied Motion, TECNOTIO, Parker, etc.

Kollmorgen, as a brand of Danaher Motion, is a global leading motion control system provider and a leading company in the international frameless torque motor market.

As the humanoid robot industry is still in its early stages and has not yet achieved mass production, there is no obvious magnitude difference in the production capacity of frameless torque motors among major manufacturers. In addition, due to the relatively low technical barriers, the first-mover advantage of frameless torque motors is less sustainable. Therefore, it is particularly important for frameless torque motor manufacturers to be the first to enter the humanoid robot supply chain.

HONEST Automation can provide humanoid robot frameless motor, frameless torque motor and joint motor winding assembly equipment. At present, we have provided corresponding motor equipment to world-renowned humanoid robot companies. Welcome to consult for customized automation equipment solutions.