We all know that developing new energy vehicles is a strategic method for tackling climate change and striving for green development. With the vigorous development of a new round of global technological revolution and industrial transformation, the accelerated integration of automobiles with related technologies in the fields of energy, transportation, information and communication, electrification, internet connectivity and intelligence has become the development trend of the automobile industry. Thus, the requirements for drive motors are also getting higher and higher, requiring them to be more efficient, longer-lasting, lighter and more energy-saving and so on, in which hairpin wire motors play a significant role in improving motor power density and efficiency.

The drive motor system, as one of the core components of new energy vehicles, which is the main execution structure of new energy vehicles during driving. It is mainly composed of electric motors, power converters, control machines and other parts. The hairpin motors are more widely used in new energy vehicles because of their advantages of low consumption, higher efficiency and reliability.

What is a hairpin motor:

A hairpin motor is an electric motor whose stator winding is done with hairpins instead of round wires. It is mainly composed of stators, rotors, bearings, end caps and other parts.

Corresponding to the hairpin motor is the circular motor, which adopts a ring coil structure. The coil usually consists of multiple wingdings that are fixed to the iron core of the motor. The structure enables the circular motor to have higher magnetic field strength and larger torque output capability, making it more suitable for some applications requiring high torque.

The Applicable scenes of the hairpin motors and circular motors:

About the hairpin motors:

1. New energy vehicles: hairpin motors can increase the recharge mileage of new energy vehicles and reduce battery costs.

2. Industrial motors: hairpin motors can improve the efficiency and reliability of industrial motors and extend their service life.

About the circular motors:

1. Household appliances: circular motors are commonly used types of motors, for example, washing machines, air conditioners, fans, and so on.

2. Industrial equipment: circular motors are also widely used in industrial equipment, such as machine tools, lifting equipment, pumps and so on.

Both the hairpin motors and the circular motors can also be used in aerospace medical equipment and other fields.

Compared with the circular motors, the advantages of hairpin motors are:

1. Smaller size. At the same power, compared to traditional circular motors, hairpin motors are smaller and use less materials, which can reduce costs;

2. Good heat dissipation performance. The interior of the hairpin motors is more compact, the gaps are smaller, the contact area between the wires is larger, and the heat dissipation and heat transfer performance is good, which can reduce the temperature of the motors and thereby improve the reliability of the motors;

3. Less noise. The wingding of hairpin motors can reduce vibration and thereby reducing the sound of equipment operation.

4. High efficiency. The winding of the hairpin motors can reduce power loss, thereby increasing efficiency. There are no gaps at the ends of the wires of hairpin motors, which can reduce power loss.

While hairpin motors have many advantages, they also have their drawbacks.

The drawbacks of the hairpin motors:

1. High loss. Hairpin motors will inevitably encounter the "skin effect" - when there is alternating current or alternating electromagnetic field in the conductor, the current distribution inside the conductor will be uneven, and the current will tend to concentrate on the "skin" part of the conductor surface.

2. Higher requirements for copper wires. Hairpin motors have higher requirements for copper wires than circular motors. It is required to have a certain degree of elasticity and a certain degree of rebound after bending. This requirement makes the design more difficult. At the same time, the insulation layer of the wire will become more susceptible to damage due to bending and rebound, resulting in gaps.

3. High production equipment requirements. Due to the complex process and high precision requirements of hairpins, it is impossible to achieve large-scale mass production through manual manufacturing. It must rely on professional high-end equipment, and the production cost is also high.

However, as a company that has been deeply engaged in the solutions for intelligent motor equipment, HONEST Automation has mature technology research and development teams and complete and mature hairpin motors production lines. We have a variety of means to solve the above problems and difficulties.

The advantages of HONEST Automation:

1. HONEST Automation has been established for a long time and has rich experience in manufacturing hairpin motors.

HONEST Automation was established in 2007. We have been deeply involved in the motor industry for more than ten years and have cooperated with leading companies in the motors or vehicles industries in Japan, South Korea, France, Mexico, Iran, India and other countries and regions. We can not only provide standardized equipment but also specialize it according to customer needs. custom made. And we have complete and professional hairpin motor production lines.

2. Our hairpin motor product lines:

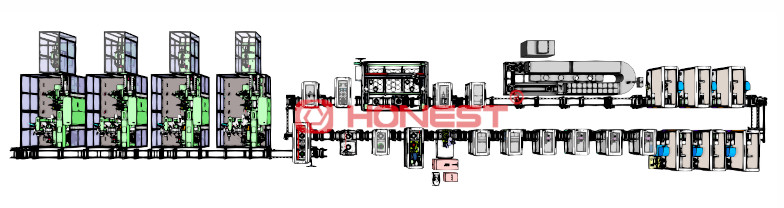

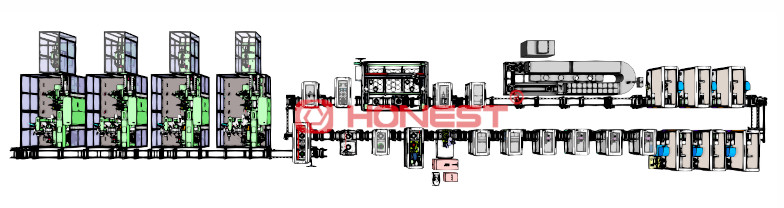

One is the hairpin motor automated production line

The hairpin motor automated production line is used in BSG motors, automotive generators, new energy drive motors, and so on. The entire line has high output. The servo motor adopts bus control, the key parts are processed independently with precision equipment, and the standard parts are all from international brands.

Intelligent functions: life management of key components, face recognition, real-time traceability, uploading and distribution of production data, and docking with MES systems.

The advantages of the equipment:

(1)High stability, mobility rate can reach more than 95%.

(2)High-speed production, reaching 48s/pcs

(3)High compatibility, and you can just switch the program formula when changing the model.

(4)High reliability and the servo motor is controlled by M3 bus control

(5)Key parts life management, face recognition, real-time tracing of production data, uploading and issuing are all connected to the MES system;

(6)Standard parts are all from international brands, and the quality can be guaranteed.

Some parameters of this equipment:

(1) Production efficiency: 48s/pcs

(2) Voltage: AC three-phase 380V

(3) Air pressure: 0.4-0.6MPa

(4) Pass rate: more than 99%

(5) Power: 30KW

(6) Full-day time utilization: more than 95%

(7) Control mode: PLC bus control

(8) Overall dimension:12000(L)*9000(W)*2500(H)mm

PS: Specific parameters can be adjusted according to customer requirements and product design.

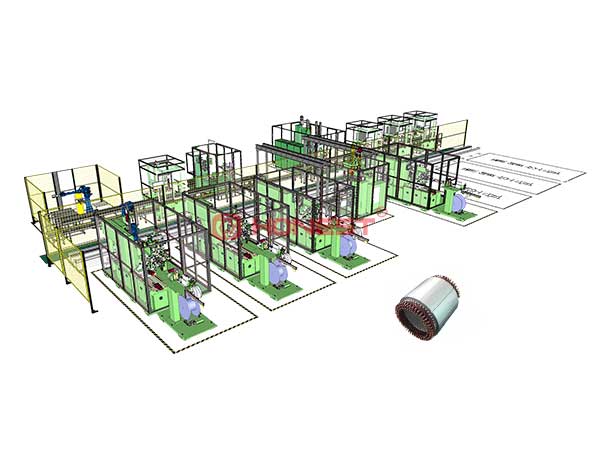

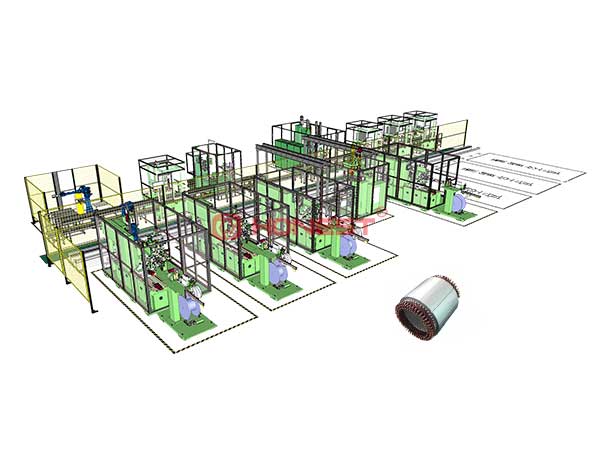

The other is the new energy hairpin motor stator assembly production line

The new energy drive motor stator assembly production line can be used in new energy vehicle drive motors, generators and other fields. The standard parts used across the entire line are from internationally renowned brands. The servo motor is controlled by bus, and the key components are processed independently using precision equipment. This production line can achieve fully automatic production of 3-wire 6-layer, 4-wire 8-layer, 5-wire 10-layer and 6-wire 12-layer.

Intelligent functions: the production data can be traced in real-time, uploaded and distributed, and connected with the EMS; it has a recognition system.

Advantages of this equipment:

1. The insulating paper is reliably formed and inserted into the stator core, and the insertion and cutting length of the insulating paper is stable;

2. After the expansion, the circumferential consistency of the thread ends of each turn is ensured, which facilitates the positioning of the thread ends in the subsequent thread twisting process;

3. After cutting the copper wire flat, polish the cutting head to obtain better laser welding quality;

4. Laser is used to weld the wire ends, which has high welding quality, high efficiency and good reliability.

5. The BUSBAR automatically aligns and is positioned and assembled with the same fixture as the stator to ensure the stability of the assembly.

Some parameters of this device:

1. Production efficiency: 30-50 units/hour

2. Voltage: AC three-phase 380V

3. Air pressure: 0.4-0.6MPa

4. Pass rate: above 99%

5. Power: 450KW

6. Full-day time utilization: more than 95%

7. Control Method: PLC bus control

8.Overall dimension:35000(L)*15000(W)*2500(H)mm

PS: Specific parameters can also be adjusted according to customer requirements and product design.

3. Advantages of specific equipment of HONEST Automation:

(1)In cutting insulating papers aspect

We can ensure the insulating papers will not deform when cutting. And the blade for cutting insulating paper can be used and replaced repeatedly, so it can save money.

(2) Broken paper detector: detects whether the insulation paper is damaged according to the set range. If it is damaged, it will automatically be regarded as a defective product and be discharged. And there is a QR Code on the equipment, you can scan it to confirm the product status anytime.

(3) Straighten: accuracy can reach 0.01 and the machine is highly compatible, can be adjusted according to the distance of the line used, no need to replace components.

(4)Paper shaping: Shezhen HONEST uses 2D folding and 3D moulding wire-making method, and one wire-making machine can complete the production of all the wire shapes of the stator.

The 2D folding step is responsible for twisting the wire, we can make the wire twisted in two directions so that we can make the ipins and a bulge on the head. The bulge design of the head can avoid it from touching the wire near it, to achieve the result of insulation;

And our equipment can detect 100% testing of voltage resistance, and automatically reject defective products, in the configuration of the line storage area, after rejecting the defective products, can be automatically identified to replenish the corresponding hairpin plug line into the wire cup, reduce downtime waiting time.

And our equipment can detect 100% pressure resistance online and automatically remove defective products. In the configuration line storage area, after rejecting defective products, can be automatically identified to replenish the corresponding hairpin plug line into the wire cup, reducing downtime and waiting time.

4. The advantages of technologies of HONEST Automation:

(1)We have strong R&D strength and can provide manual, semi-automatic and fully automatic production lines, you can choose which is your need.

(2)We can provide a complete set of overall solutions for drive motor A samples, B samples, small batch processing, mass production processing, and mass production line equipment delivery.

You can try the sample at a lower price first, and then put it into production lines if you are satisfied, which can greatly save you money.

(3)We have a complete internal processing and outsourcing processing system, which can greatly shorten the delivery time and control it within 6 months.

(4)We can provide customized services according to your product design and needs until you meet your requirements.

If you have any needs or questions, please feel free to contact us:

Tel/Wechat/WhatsApp: +8618923732990

E-mail: sales@honest-hls.com