Honest Automation has recently achieved a significant milestone: through the implementation of 6S management practices, the company successfully secured an order from a globally renowned automaker. This accomplishment not only demonstrates our commitment to excellence but also marks Honest Automation’s growing capability to deliver internationally competitive products and services.

Comprehensive 6S Training Led by Manager Luo

To further enhance overall management standards and build a safer, more efficient, and standardized workplace, Manager Luo from Honest Automation’s HR & Administration Department recently delivered a comprehensive 6S management training session for managers and frontline employees. The training deepened employees’ understanding of 6S principles and provided practical guidance on integrating them into daily operations.

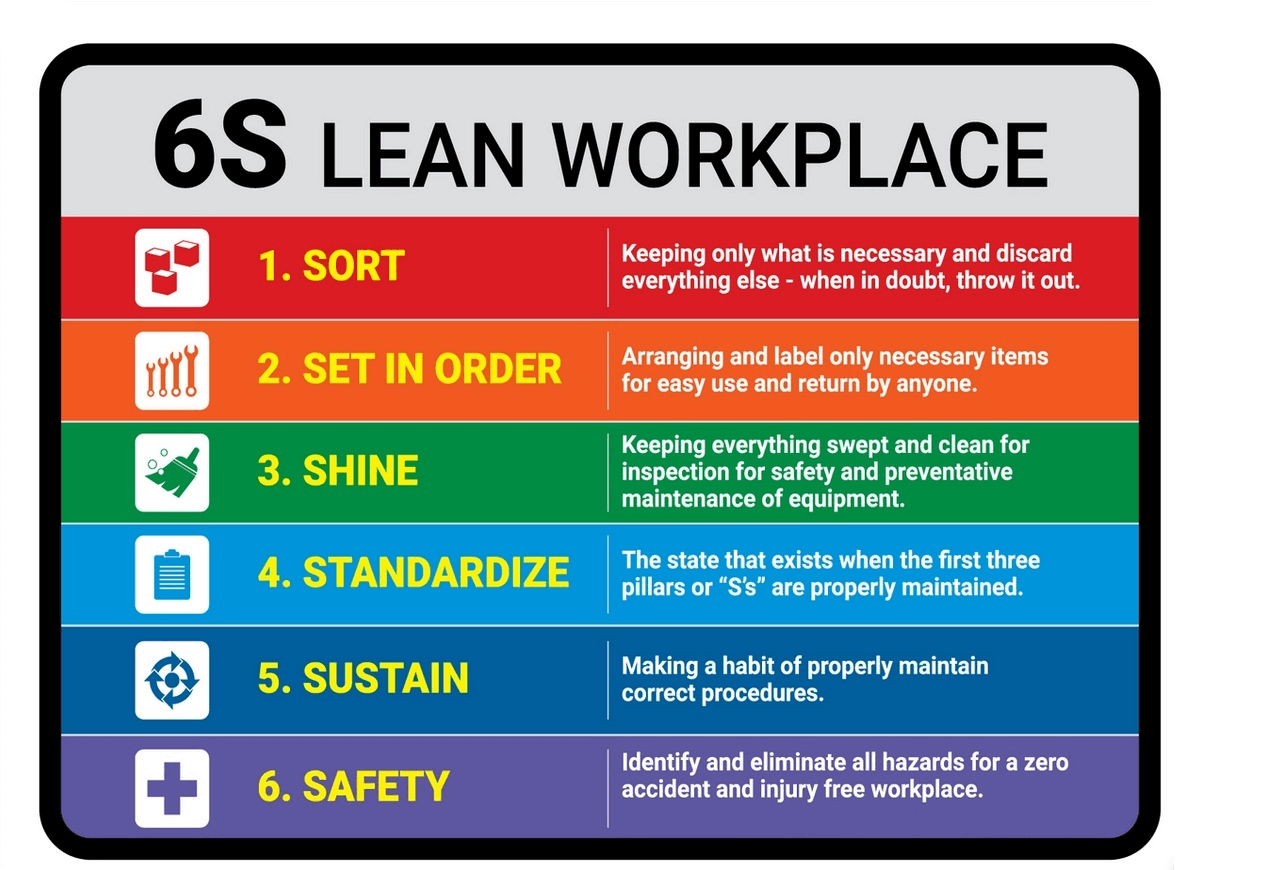

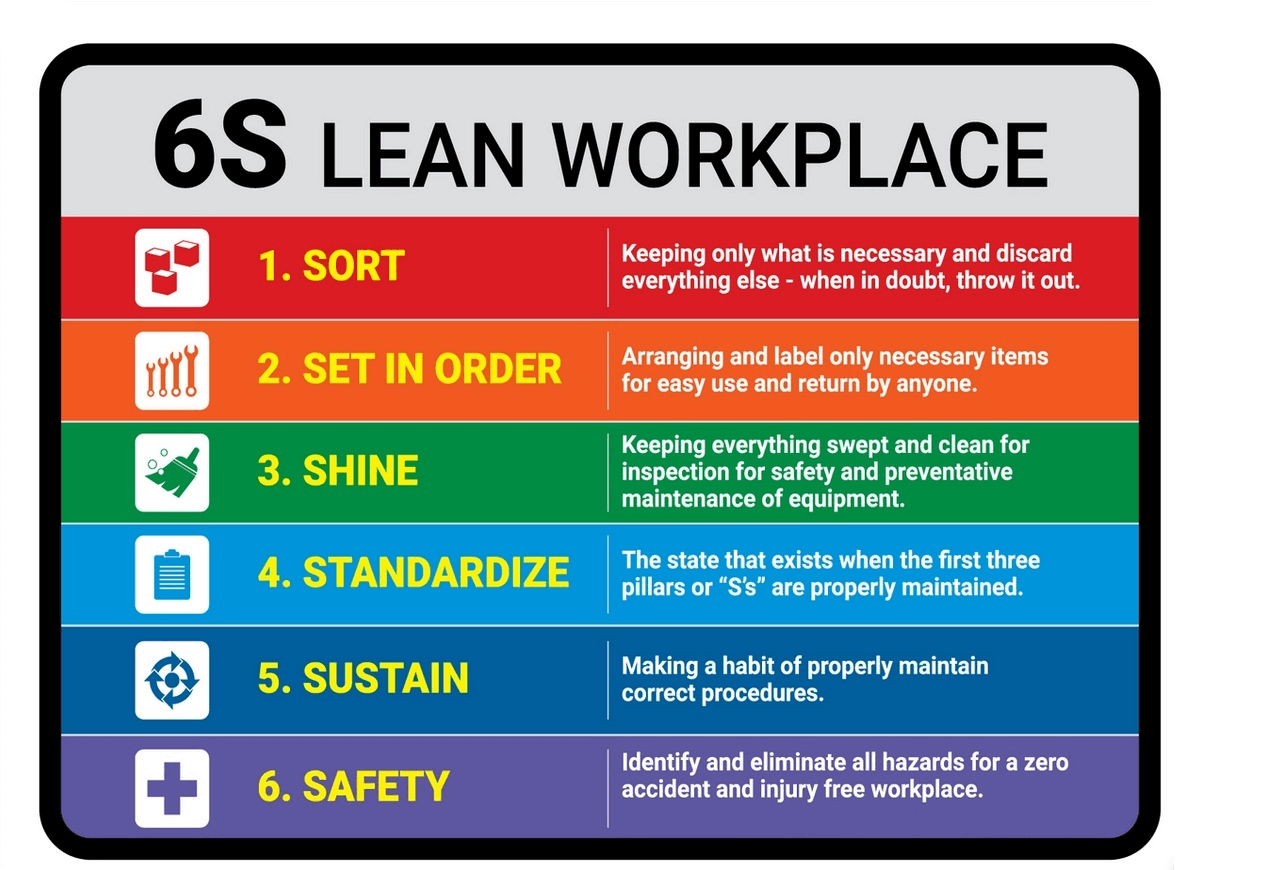

What is 6S Management?

6S management, originating from best practices in Japanese enterprises, is now widely adopted across modern industries. It encompasses six elements: Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), Shitsuke (Sustain), and Safety. By combining structured processes with full employee engagement, 6S aims to establish a workplace that is clean, orderly, safe, and highly efficient.

Benefits of 6S Implementation

During the training, Manager Luo emphasized the multiple benefits that 6S management brings to an enterprise:

Improved Product Quality – By standardizing workflows and equipment management, defects and errors are reduced, ensuring consistency and reliability.

A Safer and Healthier Workplace – Sorting and cleaning eliminate potential hazards, creating a more comfortable and secure environment.

Reduced Equipment Failures – With a proactive maintenance mindset, fault rates are minimized, and machine lifespan is extended.

Higher Efficiency – Proper organization ensures tools and materials are easy to access, significantly boosting productivity.

A Strong Safety Culture – Cultivating discipline and safety awareness nurtures positive habits and strengthens the company’s corporate culture.

Looking Ahead

The training session was highly engaging, with employees actively participating in discussions and reflecting on how to apply 6S concepts in their daily roles. Through vivid case studies and interactive exchanges, Manager Luo highlighted that “6S is not just a management tool but a culture of continuous improvement.”

Moving forward, Honest Automation will use this training as a foundation to strengthen inspection and evaluation mechanisms, ensuring that 6S standards are rigorously applied across all departments. Weekly audits will be carried out to track progress and guarantee that 6S principles become fully embedded in everyday operations.

With the philosophy of “improving quality through management and winning trust through quality,” Honest Automation will continue to optimize its production environment and processes. By adhering to world-class management standards, we are committed to providing customers with highly efficient and reliable automation solutions. On the journey of 6S management, Honest Automation will continue to progress steadily—delivering excellence every step of the way.