In the field of motor manufacturing, it's common for companies to focus on price before evaluating motor assembly machine.

While price is undoubtedly an important factor in procurement decisions, relying solely on it—while overlooking the equipment’s technical capabilities and its critical role in production—can lead to costly mistakes.

Rushing into price negotiations without fully understanding key aspects such as performance specifications, quality assurance, and service support may expose the business to significant risks. These include insufficient assembly accuracy, poor operational stability, higher maintenance costs, and potential delays in production schedules or declines in product quality.

Perhaps the previous point isn’t intuitive enough—let’s look at a real-world example.

A motor manufacturing company intended to introduce an advanced motor assembly system to improve production efficiency and product quality. Initially, the company reached a preliminary agreement with the equipment supplier on production needs and technical requirements. However, upon learning that the equipment cost was relatively high, the company decided to withdraw and began evaluating alternative suppliers with lower prices.

Although this decision appeared to reduce procurement expenses in the short term, it ultimately led to several negative consequences. Without the support of advanced equipment, the company faced frequent issues with assembly accuracy and inconsistent product quality during subsequent production. As a result, after-sales maintenance costs increased significantly. Additionally, limited equipment performance failed to deliver the expected improvement in production efficiency, causing the company to gradually lose its competitive edge in the market.

So, in light of this case, what key factors should motor manufacturers consider to make the right decision when selecting motor assembly line?

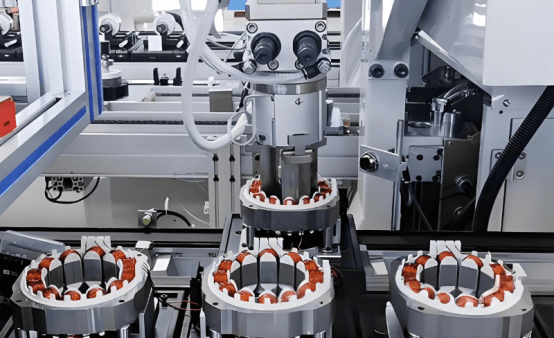

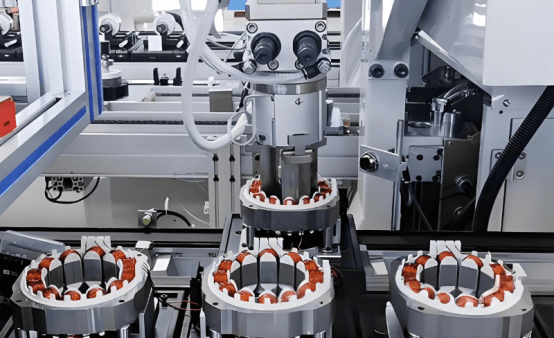

First and foremost, technical performance is the core competitiveness of any equipment. Critical factors such as precision, operational stability, and the level of automation directly impact the quality of motor assembly. High-precision equipment ensures tighter assembly tolerances, which is essential for enhancing motor efficiency and long-term reliability. Meanwhile, stable equipment performance minimizes downtime and breakdowns, resulting in higher production efficiency and consistent output.

Secondly, it is essential to choose a supplier with a well-established quality assurance system to ensure long-term operational stability of the equipment. This minimizes unplanned downtime and maintenance costs caused by equipment failures.

Furthermore, the motor market is constantly evolving, with frequent changes in product models and specifications. Manufacturers must stay agile in adapting their production strategies. A motor assembly system with strong compatibility and scalability can accommodate various motor types and allow for future upgrades or modifications, eliminating the need for frequent equipment replacement and reducing both capital investment and operational risk.

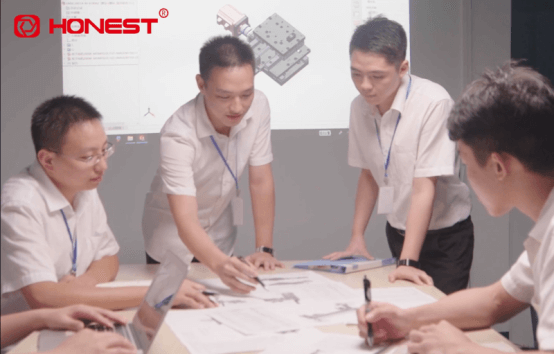

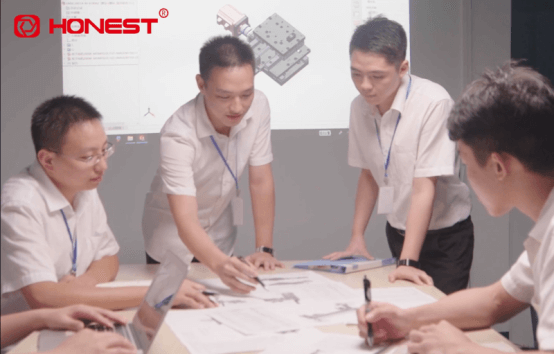

Lastly, the supplier’s R&D capability should be a key consideration in the selection process. Suppliers with strong innovation capabilities are better positioned to deliver cutting-edge and competitive equipment solutions. Their ability to continuously develop advanced technologies can empower motor manufacturers to maintain a leading edge in a dynamic and competitive market.

In the field of intelligent motor equipment, HONEST Automation stands out as a professional provider of comprehensive motor assembly solutions. Leveraging its strong technological expertise, HONEST has delivered efficient and reliable equipment support to numerous motor manufacturers. Our equipment is characterized by high precision, exceptional stability, and a high degree of automation, significantly improving the efficiency and quality of motor assembly processes.

Moreover, we place great emphasis on quality assurance, both before and after equipment deployment. Through a robust quality management system, every unit undergoes rigorous testing to ensure consistent reliability and long-term performance, providing our customers with stable and dependable production support.

In conclusion, motor manufacturers should move away from price-driven procurement strategies and instead prioritize critical factors such as technical performance, quality assurance, compatibility, and scalability when selecting assembly equipment.

At HONEST Automation, we are committed to continuous technological innovation driven by market demand. We offer a range of advanced motor assembly solutions aligned with industry trends, empowering manufacturers to enhance productivity, support future expansion, and stay competitive in a rapidly evolving market.