Humanoid robots are rapidly transforming industries such as service, healthcare, logistics, and manufacturing. Their ability to mimic human motion and interact naturally depends heavily on the precision and efficiency of their internal systems—especially the motor systems powering their joints and movements. Motors like joint motors, frameless motors, and torque motors are critical components in ensuring smooth, reliable operation. As the demand for high-performance humanoid robots rises, so too does the need for advanced motor assembly solutions that can meet strict precision, consistency, and scalability requirements.

Key Challenges in Humanoid Robot Motor Assembly

Assembling motors for humanoid robots poses unique challenges distinct from other motor applications:

Miniaturization & Precision: Motors for humanoid robots must fit within compact spaces, particularly at joints like shoulders, elbows, and knees. Achieving micrometer-level tolerances during assembly is crucial to ensure smooth articulation and overall robot balance.

Multi-Axis Coordination: Each humanoid robot contains dozens of motorized joints, making it essential to coordinate multi-axis motor assembly with zero margin for alignment errors.

Reliability & Durability: Humanoid robots operate under dynamic, repetitive conditions. Motor assemblies must guarantee long lifecycle performance without failures.

Customization Flexibility: Different robot designs require tailored motor specifications. Assembly lines must be flexible enough to accommodate varied motor models.

Production Cost & Efficiency: Balancing high accuracy with cost-effective, scalable production is a top priority for manufacturers.

Core Technologies in Motor Assembly Equipment

To overcome these challenges, advanced motor assembly solutions integrate several cutting-edge technologies:

Precision Automated Winding: Automated stator winding machines with tension control ensure optimal wire placement, reducing resistance and improving motor efficiency.

Laser Welding & Bonding: Laser-based welding guarantees stable electrical connections while maintaining compact motor size and minimizing thermal damage.

Intelligent Assembly Systems: Real-time monitoring systems, torque control devices, and vision-guided assembly robots enhance precision and reduce assembly errors.

Flexible Multi-Station Lines: Modular production setups can quickly adapt to different motor types and production volumes, from prototypes to mass production.

AI-Based Quality Inspection: Advanced inspection systems identify defects at every stage, ensuring strict quality standards and data traceability.

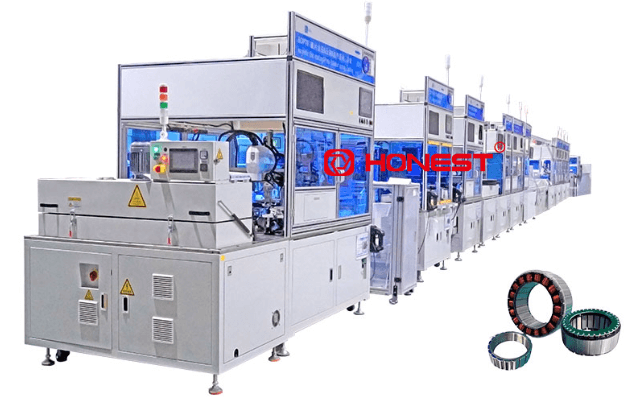

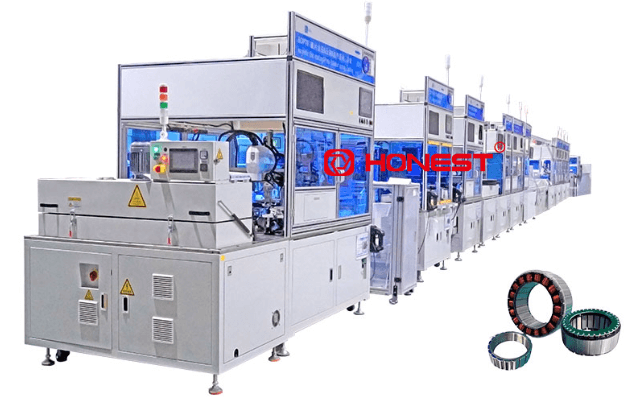

Customized Solutions for Humanoid Robot Manufacturers

Our motor assembly lines are fully customizable to address specific needs of humanoid robot manufacturers. For instance:

Joint Motor Assembly Lines: Specially designed for assembling shoulder, knee, and ankle joint motors, ensuring smooth rotation and load-bearing capacity.

Frameless & Torque Motor Solutions: Tailored systems for high-torque, space-constrained applications, common in humanoid robots' critical movement areas.

Compact Drive Motor Assembly Lines: Ensuring efficient, reliable power delivery while maintaining a minimal footprint.

Each solution is modular, allowing seamless adjustments for different product models and production targets.

Benefits of Advanced Motor Assembly Solutions

By leveraging advanced motor assembly technologies, manufacturers can achieve:

High Precision: Enabling better motion control and robot dexterity.

Reduced Cycle Time: Improving overall production efficiency and lowering costs.

Enhanced Consistency: Minimizing defect rates and ensuring product reliability.

Scalability: Smooth transition from R&D samples to large-scale production.

Full Traceability: Ensuring every step of the process is monitored and recorded for quality assurance.

Future Trends in Humanoid Robot Motor Assembly

Looking ahead, we foresee several key trends shaping the future:

AI-Powered Adaptive Assembly: Assembly systems will become more autonomous, adjusting parameters in real-time based on data feedback.

Smart Factories: Fully unmanned, data-driven production environments will streamline motor manufacturing.

Sustainable Production: Eco-friendly manufacturing practices, including energy-efficient equipment and waste reduction, will become standard.

Closer OEM Collaboration: Humanoid robot developers will increasingly co-design motor assembly solutions with equipment suppliers to achieve optimal integration.

Efficient, precise motor assembly is the backbone of advanced humanoid robots. At HONEST Automation, we specialize in providing high-performance humanoid robot motor production line. Our solutions are fully customizable, and tailored to meet the unique demands of each client, whether for joint motors, frameless motors, or drive motors. We offer one-stop services including consultation, equipment design, localized installation, and after-sales support to help you streamline your production and stay ahead of the competition.

Are you looking for reliable, efficient motor assembly solutions for your humanoid robots? Contact HONEST today to discuss your customized production needs.