Case Study: Automotive Oil Pump Brushless Stator Assembly Line Delivered to the Customer’s Factory

Customer Profile

The customer is a global leader in comprehensive motor manufacturing, headquartered in Japan, and has been ranked among the World’s Top 500 Companies. The group comprises approximately 140 subsidiaries, with operations spanning production, R&D, and sales networks across Japan, China, the United States, and other regions worldwide. Through strategic acquisitions, the company has further expanded into emerging fields such as semiconductors, artificial intelligence, eVTOL electric aircraft, and robotics.

The customer’s motors are widely used in the automotive, home appliance, robotics, logistics, medical, and industrial sectors, with its brushless DC motors and hard disk drive spindle motors holding leading positions in the global market.

Project Background & Challenges

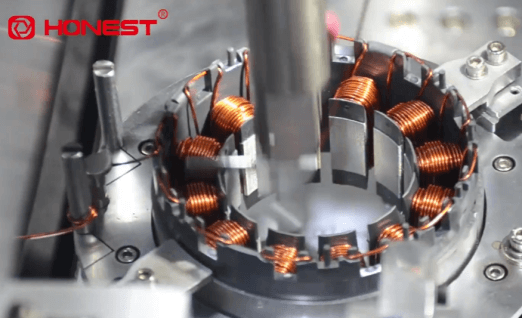

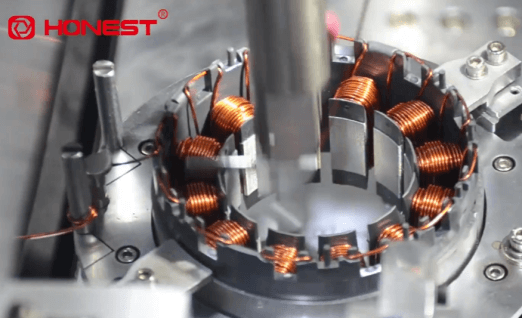

The customer required an automated solution for assembling brushless stators used in automotive oil pump motors. The core challenges centered on segment stator round-forming and quality testing. Specifically, achieving consistent stator shaping and ensuring reliable inspection results were critical, as any inconsistency could impact downstream assembly and overall motor performance.

Solution Provided by Honest Automation

Honest Automation delivered a fully automated brushless stator production line designed to address these challenges. The solution covers the entire workflow from QR code marking, automated feeding, winding, round-forming, assembly, quality sorting, to final output. The line integrates CCD vision systems and barcode scanning to enable full traceability, reduce defect rates, and ensure process stability.

Key Equipment Features

Fully automated winding and round-forming: All winding and round-forming operations are completed automatically, ensuring consistency and efficiency.

Traceable production: CCD cameras and barcode scanning track each stator throughout production, lowering defect rates.

High-speed operation: Achieves a full-line cycle time of 24 seconds per unit.

Automated feeding and discharge: Stators are loaded manually into molds, then automatically fed via a dual-speed chain; finished products are picked up by robotic arms.

Compact and efficient design: Winding machine dimensions: 2258×1194×1700 mm; round-forming machine dimensions: 1773×1893×1938 mm.

Low manpower requirement: Only one operator is needed to supervise the line.

Performance & Results

Full-line cycle time: 24s per unit

Assemblable brushless segment stators for automotive applications

Consistent and stable product quality with reliable inspection

Traceable production data allows for ongoing quality analysis and improvement

Minimal manpower required, maximizing operational efficiency

Why Honest Automation

Provides tailored support for the customer’s stator structure and manufacturing processes.

Extensive experience with leading global motor and automotive manufacturers demonstrates that the technology is proven and industry-leading.

Equipment and production lines are standardized and market-validated through multiple tests and real-world applications, minimizing operational risk.

High stability and reliability of lines, with modular design allowing easy upgrades and adaptation for future product variations.

Application & Scalability

This brushless stator production line is suitable for automotive applications and can be adapted for other motor types with similar requirements. Its modular design enables easy replication, scalability, and process upgrades to meet evolving customer demands and higher production volumes.

In addition to the automotive oil pump brushless stator assembly line, we have supplied the customer with a wide range of equipment, including rotor winding machines, rotor precision lathes, printer motor production lines, stator prototyping equipment, single-axis stator winding machines, stator and housing assembly lines, brushless stator assembly lines, segment winding machines, and stator round-forming winding equipment.

Thanks to Honest Automation’s timely support and efficient after-sales service for the customer’s production lines, we were honored with the “Technical Breakthrough Supplier Award” in 2022 and the “Technical Innovation Award” in 2024, recognizing our technological capabilities and service excellence.