In the automobile’s precision mechanical system, the cooling system is a key link to ensure the stable operation of the engine. It not only maintains the engine at optimal operating temperature and prevents overheating, but also plays a vital role in improving the overall performance and reliability of the vehicle. As the core component of the cooling system, the performance of the radiator fan motor directly affects the cooling efficiency.

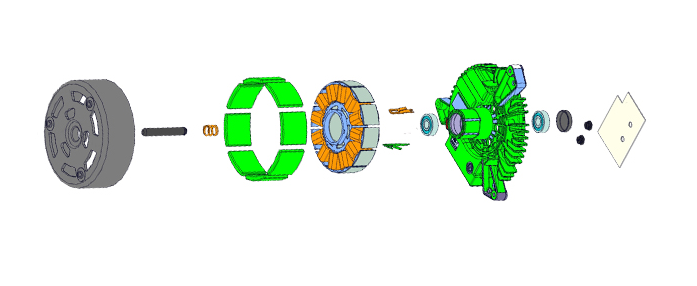

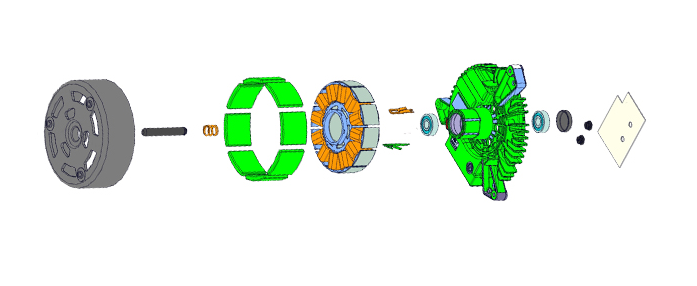

The automotive radiator fan motor typically consists of the following main components

Motor Housing: It is the core part of the fan motor, which usually contains the stator and the rotor. The stator is the stationary part, while the rotor rotates within the magnetic field generated by the stator.

Motor Stator: It is the stationary part of the motor, usually composed of a series of winding that produce a magnetic field when electrified.

Motor Rotor: It is the rotating part of the motor, which interacts with the stator’s magnetic field to generate a torque that drives the fan blades.

Fan Blades: They are the parts directly connected to the rotor, and they rotate under the drive of the rotor to produce airflow.

Bearings: They are used to support the rotor, reduce friction, ensure smooth operation of the motor, and extend the service life of the motor.

Electronic Control Unit (ECU): In the Electronically Controlled Fan (ECF) system, the ECU is responsible for controlling the speed of the fan motor based on the engine temperature and other sensor data, achieving precise cooling control.

Sensors: Sensor components such as temperature sensors monitor the temperature of the engine and coolant and transmit data to the ECU for corresponding control decisions.

Connectors and Wires: They are used to connect the motor and other electronic control units to ensure the transmission of electrical energy and signals.

Housing: It not only serves to protect internal components but also helps with heat dissipation and securing the position of the motor.

Mounting Brackets: They used to secure the fan motor within the radiator or engine compartment to ensure stable operation.

The Working Principle of Automobile Radiator Fan Motor

The main task of the car radiator fan motor is to drive the radiator fan to promote air circulation and accelerate the dissipation of heat. In a traditional mechanical radiator fan system, the fan motor is usually driven by the engine’s belt, and its speed is proportional to the engine speed. However, with the development of automotive electronics technology, electronically controlled fan (ECF) systems have become the new industry standard due to their higher energy efficiency ratio and precise control capabilities. The ECF system intelligently adjusts the fan speed through the electronic control unit (ECU) based on engine temperature, load, and other sensor data to achieve precise cooling control.

The Types of Automotive Radiator Fan Motor

A. Mechanical Fan Motor

Traditional mechanical fan motors are driven directly by the engine via a belt. They have a fixed speed ratio to the engine’s rotational speed, offering simplicity and low maintenance. However, they lack the ability to adjust fan speed based on varying cooling demands.

B. Electronically Controlled Fan (ECF) Motor

ECF motors are managed by an Electronic Control Unit (ECU), which adjusts the fan speed dynamically based on engine temperature and other sensor inputs. The type of motor provides precise cooling control and enhances overall energy efficiency.

C. Pulse Width Modulation (PWM) Fan Motor

Pulse Width Modulation fan motors use a varying duty cycle of a square wave signal to control the speed of the motor. The method allows for fine-grained speed adjustments, optimizing cooling efficiency and energy consumption.

D. Direct Current (DC) Fan Motor

DC fan motors operate on direct current and can be precisely controlled by the ECU through PWM signals. They are known for their high efficiency and quick response, making them suitable for applications requiring accurate control.

E. Alternating Current (AC) Fan Motor

AC fan motors are designed for applications requiring higher power. They are compatible with the vehicle’s AC power systems and provide robust cooling capabilities.

F. Brushless Direct Current (BLDC) Fan Motor:

BLDC motors replace traditional brushes with electronic commutation, reducing maintenance and wear. They are favored for their high efficiency, low noise, and longevity.

G. Hybrid Fan Motor

Hybrid designs combine two or more technologies. For example, a mechanical fan might be supplemented with an electronic control unit to provide additional cooling capacity under high-load conditions.

The Application of Automobile Fan Motor

In modern vehicles, radiator fan motor applications have expanded into battery pack cooling and air condition systems. As the level of automotive electronics improves, the control strategy of fan motors has become more intelligent and can automatically adjust according to the actual working status and environmental conditions of the vehicle to adapt to changing cooling needs.

The Function of the Automotive Radiator Fan Motor

Maintain Engine Temperature: The primary function of the radiator fan motor is to maintain the engine temperature within an ideal operating range. By driving the fan, it helps the coolant to absorb and dissipate the heat generated by the engine.

Prevent Overheating: During high-load operation or high-speed driving, the heat generated by the engine can increase significantly. The radiator fan motor effectively prevents engine overheating by increasing the flow of cooling air.

Improve Fuel Efficiency: The engine operates at its most fuel-efficient temperature. The radiator fan motor indirectly improves fuel efficiency by maintaining this temperature.

Protect Engine Components: Continuous high temperatures can accelerate the wear and aging of engine components. The radiator fan motor extends the service life of the engine by effectively dissipating heat.

Enhance Driving Comfort: An overheated engine can affect the driving experience. The radiator fan motor enhances driving comfort by maintaining a suitable engine temperature.

The Professional and Technical Advantages in the Field of Automotive Fan Motors of HONEST Automation

HONEST Automation focuses on the R&D and manufacturing of electrical equipment and has several industry-leading patented technologies. In the field of automotive fan motors, our advantages are reflected in:

A. High-precision sensors and advanced visual inspection systems are used to ensure product accuracy and reliability;

B. The equipment has detection functions for leakage prevention, under-installation, and incorrect installation, as well as post-installation quality inspection to ensure that the product meets the highest standards;

C. The design follows ergonomic principles to simplify the operating process and improve user experience;

D. The equipment has a built-in safety protection mechanism, including door opening and air pressure safety protection, to ensure safe operation;

E. The real-time monitoring system can prompt various misoperations and bad conditions, improving the safety and convenience of operations.

When an abnormality occurs in the equipment, the system can display an abnormal alarm on the screen and point out the abnormal location to facilitate quick diagnosis and processing.

With the rapid development of the automobile industry, the performance requirements for radiator fan motors are also constantly increasing. HONEST HLS is committed to providing efficient, intelligent, and reliable automotive radiator fan motor products through technological innovation to meet the high standards of the market. We look forward to working with you to jointly promote the development of automotive cooling technology and contribute to the progress of the global automotive industry.

If you are interested in automobile fan motor assembly line or are looking for automation equipment, please consult us for customized solutions and quotes.