Electric Parking Brake (EPB) is a device that converts electrical energy into mechanical energy, an electronically controlled parking brake system that replaces the traditional mechanical handbrake, offering a more convenient and safer vehicle parking solution.

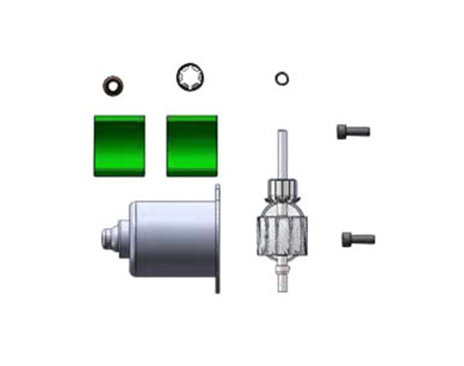

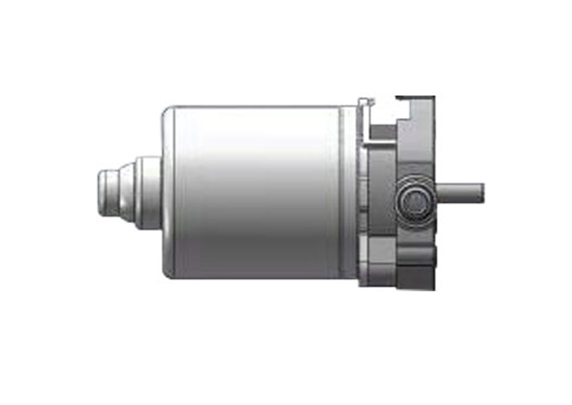

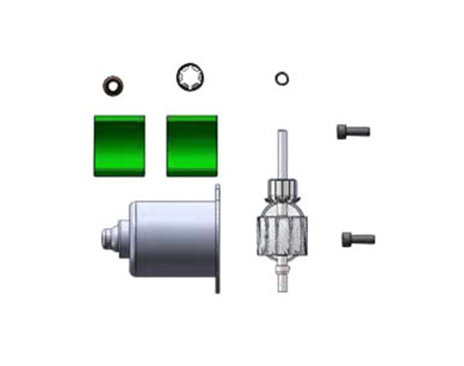

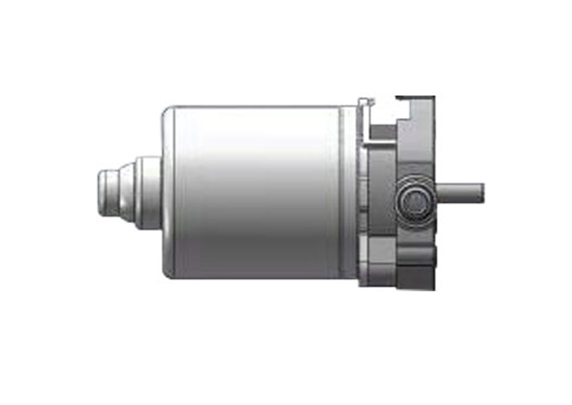

Structure of the Electric Parking Brake Motor

The EPB motor is the core component of the electric parking brake system, responsible for driving the brake to achieve the automatic parking function. It is usually a direct current motor that, through the supply of power voltage, transforms electrical energy into mechanical energy to generate braking force. It is typically composed of the following parts:

A. Motor: The motor acts as a power source, responsible for generating sufficient torque to drive the braking mechanism.

Motor Stator: It is the stationary part of the motor, usually containing coil winding to generate a magnetic field.

Motor Rotor: It is the rotating part of the motor, typically made of permanent magnetic material to respond to the magnetic field produced by the stator.

B. Reduction Mechanism: It is used to reduce the motor’s speed and provide sufficient torque output.

Gearbox: It contains multiple gears to reduce motor speed and increase torque.

Worm Gear: It is another type of reduction mechanism, composed of a worm wheel and worm rod, used to achieve a high reduction ratio.

C. Transmission Components: They transfer the rotation of the motor to the braking mechanism to achieve the tightening or release of the brake pads.

Belt or Chain: It transfers the output of the reduction mechanism to the brake actuator;

Gears: In some designs, gears may be used to directly connect the reduction mechanism and brake actuator.

D. Brake Actuator

Linear Actuator: It converts the motor’s rotary motion into linear motion to push the brake;

Hydraulic Actuator: In some systems, the motor may drive a hydraulic pump to achieve braking through the hydraulic system.

E. Position Sensor: It is used to monitor the position of the motor shaft or brake to ensure the brake is in the current parking or release position.

F. Electronic Control Unit (ECU): It is responsible for receiving the driver’s commands, controlling the start, stop, and speed of the motor, and achieving precise braking control.

G. Power and Signal Interface: It provides electricity to the motor and communicates with other electronic systems of the vehicle.

H. Safety Mechanisms: They include overload protection, temperature monitoring, and so on, to ensure the safe operation of the motor under various conditions.

I. Housing and Enclosure: It protects internal components from environmental influences while providing sufficient rigidity and heat dissipation performance.

Working Principle of the Electric Parking Brake Motor

1. Command Input: The driver sends a parking or release command to the ECU through the EPB button.

2. Signal Processing: The ECU calculates the required braking force based on the vehicle’s status.

3. Motor Activation: The ECU sends an activation signal to the motor, which begins to rotate, generating power.

4. Power Transmission: The motor converts the rotational movement into linear motion through the reduction mechanism and transmits it to the brake actuator via the transmission components.

5. Braking Execution: Upon receiving the power, the brake actuator pushes the brake into operation, achieving the braking or release of the wheels.

6. Position Feedback: The position sensor monitors the position of the brake and feeds back the information to the ECU to ensure the brake is working correctly.

Advantages of Electric Parking Brake Motor

1. Automation and Convenience: The EPB motor can automatically execute parking and release operations, providing great convenience to drivers and reducing the need for manual operation.

2. Precise Control: The motor can precisely control the braking force to ensure the stability of the vehicle on slopes or different road surfaces.

3. Rapid Response: The electric system can quickly respond to the driver’s commands to achieve rapid parking and release.

4. Integration: The EPB motor can be integrated with other electronic systems of the vehicle to provide more advanced automated functions.

5. Low Maintenance: The electric system reduces mechanical wear and tear, thus requiring less maintenance and extending the service life.

Disadvantages of the Electric Parking Brake Motor

1. Cost: The cost of the EPB motor and its control system is usually higher than that of traditional mechanical handbrake systems.

2. Dependence on Electricity: The electric system relies on the vehicle’s power supply, and if there are issues with the vehicle’s battery or electrical system, it may affect the normal operation of the EPB.

3. Complexity: The electronic control system of the EPB motor is relatively complex and may require more specialized diagnostics and repairs.

4. Fault Diagnosis: Compared to traditional handbrakes, diagnosing faults in the electric system may be more complicated, requiring specialized tools and knowledge.

Classification of Electric Parking Brake Systems

EPB systems are primarily divided into two types: Cable-Actuated and Caliper-Integrated.

A. Cable-Actuated EPB: It utilizes an electrically driven mechanical device to operate traditional cables and brakes.

Working Principle

The system consists of an electric motor, a reduction mechanism, a winding drum, and steel cables;

The motor receives electronic signals from the EPB button, drives the reduction mechanism, and subsequently rotates the drum;

The steel cables wind and unwind from the drum, engaging or disengaging the brake on the rear wheels of the vehicle.

Features

Compatibility: Easy to integrate with traditional mechanical handbrake systems;

Cost: Generally less expensive than Caliper-Integrated systems;

Maintenance: It requires regular inspection and maintenance for wear on the cables and drum.

B. Cali[er-Integrated EPB: An electric parking brake system where the motor and brake are integrated within the brake caliper.

Working Principle

The system comprises an electric motor, a reduction mechanism, and a brake caliper;

The motor receives electronic signals and drives the reduction mechanism, converting rotational movement into linear motion;

The linear motion directly acts on the brake within the brake caliper to achieve the braking of the wheel.

Features

Compactness: Components are integrated into a single unit, occupying minimal space;

Rapid Response: The motor is directly connected to the brake, resulting in quick response times.

C. Comparison

Space Occupation: Cable-Actuated systems require sufficient space for the layout of drums and cables, which may occupy more space; Caliper-Integrated systems, due to the elasticity of the cables and the inertia of the drums; Caliper-Integrated systems have faster response times due to direct connection between the motor and the brake.

Response Speed: Cable-Actuated systems may have slightly slower response times due to the elasticity of the cables and the inertia of the drums; Caliper-Integrated systems have faster response times due to the direct connection between the motor and the brake.

Maintenance and Reliability: Cable-Actuated systems may require more frequent maintenance to check for wear on the cables and the condition of the drums; Caliper-Integrated systems are generally more reliable with lower maintenance needs due to the reduction of mechanical connections.

Applicability: Cable-Actuated systems are suitable for models that require cost-effective solutions or where significant modifications to the vehicle design are challenging; Caliper-Integrated systems are suitable for new high-end models that pursue high technological integration, compact design, and advanced safety features.

Development Trends of Electric Parking Brake Motor

1. Technological Integration: With the continuous development of automotive electronics technology, the level of integration of EPB motors is constantly improving. In conjunction with in-vehicle CAN bus communication and ECU control, this provides a safer and more comfortable parking experience for drivers.

2. Intelligent Development: The in-depth development of autonomous driving and intelligent driving technologies has set higher safety standards and intelligent requirements for EPB motors. In the future, EPB motors will work more closely with the vehicle’s ADAS and V2X technologies to achieve the integration of functions such as automatic parking and emergency braking assistance.

3. Low Energy Consumption and Long Life: EPB motors will also focus on characteristics such as low energy consumption, long life, and maintenance-free operation to meet the special needs of new energy vehicles and intelligent connected vehicles.

4. Increasing Market Penetration: Against the backdrop of the gradual rise in the global development trend of automotive automation and electrification, the market penetration of EPB motors is continuously increasing, showing a good development prospect.

5. Market Size Growth: The global EPB motor market size is expected to continue growing, with the Chinese market being one of the main consumer markets globally, with a growth rate higher than the global average.

In all, the technological development of electric parking brake motors shows characteristics of integration, intelligence, low energy consumption, and long life, and the market penetration and market size are expected to continue to grow.

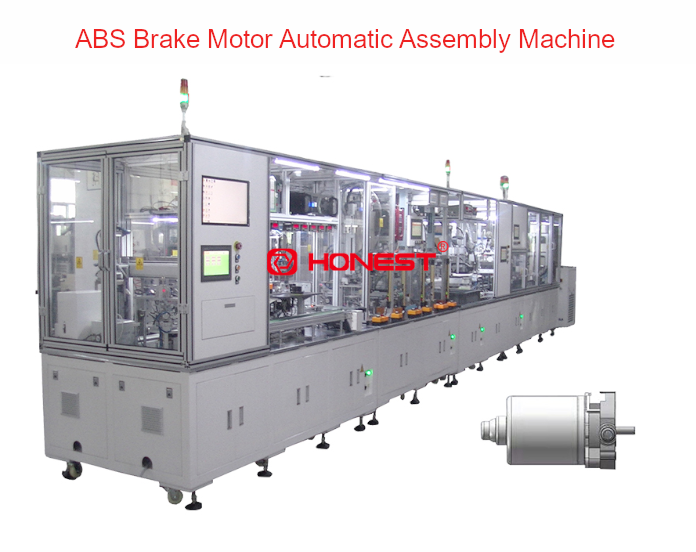

About HONEST Automation

HONEST Automation has over 18 years of R&D and production experience in the field of motor winding assembly equipment, with more than 600 successful motor production line cases. It has cooperated with well-known automotive brands and motor manufacturers and has a mature team of solution designers to handle customized customer needs. Moreover, HONEST Automation has successful cases of upgrading existing production lines and integrating automated equipment for well-known automotive parts companies, which can meet customers’ needs for equipment iteration and updates, while also minimizing the cost of investment and reducing equipment downtime.