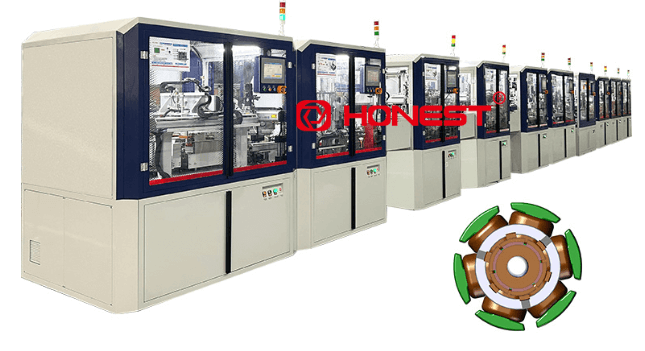

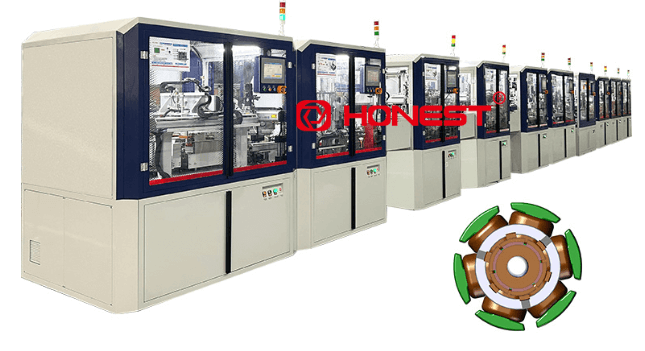

Case Study: Automotive Seat Motor Assembly Line Delivered to a Korean Tier Supplier

Customer Profile

The customer is a technology-driven company specializing in motion and control solutions for automotive systems. Its product portfolio covers electric motors, actuators, magnetic sensing technologies, and electronically controlled braking modules, serving a wide range of vehicle applications.

With strong engineering capabilities, the customer provides system-level solutions, integrating motors, gear mechanisms, control electronics, and ECU software to meet demanding automotive performance and reliability requirements. The company places particular emphasis on system integration, NVH optimization, and long-term operational stability.

Project Background & Challenges

As market demand increased, the customer faced growing pressure to scale up production of automotive seat motor components while maintaining consistent quality standards.

Key challenges included:

Rising labor costs and reliance on manual operations.

Increasing complexity due to multiple product variants.

The need for higher production efficiency and a stable takt time.

Strict automotive quality and safety requirements.

The customer sought an automated solution capable of supporting efficient, repeatable, and scalable production, without exposing proprietary process know-how.

Solution Provided by Honest Automation

Honest Automation delivered a customized automated seat motor rotor assembly line designed specifically for automotive applications.

The solution consists of 10 integrated stations arranged in a U-shaped layout, utilizing a pallet-based transfer system combined with conveyor logistics. The line covers the complete rotor manufacturing and inspection sequence, from initial material loading through final performance verification.

All equipment was engineered in close coordination with the customer, while strictly protecting confidential process parameters and proprietary system details.

Key Equipment Features

Modular and Flexible Architecture

The production line supports multiple motor variants. Product changeover is achieved through program switching and fixture replacement, enabling fast transitions and reduced downtime.

Comprehensive Error-Proofing and Safety Design

Multi-layer poka-yoke mechanisms are implemented across the line, including sensor-based monitoring, vision inspection, orientation recognition, missing-part detection, and pressure supervision. Interlocking logic and protective systems ensure stable operation and operator safety.

Stable and Efficient Line Integration

Optimized material handling between stations, logical process sequencing, and balanced cycle times contribute to high and consistent overall efficiency.

Performance & Results

After commissioning, the production line achieved the following operational results:

Cycle Time: ≤ 12 seconds

Output Capacity: up to 300 pcs/hour (excluding external stoppages)

Changeover Time: ≤ 15 minutes

Yield Rate: ≥ 98%

Utilization rate: approximately 85%

Manpower Requirement: 2 operators per line

These results enabled the customer to significantly improve production consistency, reduce manual dependency, and enhance overall manufacturing efficiency.

Why Honest Automation

The customer selected Honest Automation based on:

Proven expertise in automotive motor automation equipment

Strong capability in customized assembly line engineering

Reliable project execution and commissioning support

A solution-oriented approach focused on long-term stability rather than short-term output

Honest Automation worked as a technical partner throughout the project, aligning automation design with the customer’s system-level engineering philosophy.

Application & Scalability

The automated seat motor assembly line is designed for automotive seating system applications and can be easily scaled or replicated to support future capacity expansion and additional production sites.

Thanks to its modular design, the solution is adaptable to similar motor and actuator manufacturing scenarios requiring high efficiency, fast changeover, and stable quality control within the automotive industry.