Successful Case: Automotive Window Regulator Motor Assembly Line in Iran

Customer Profile

The customer is a leading Iranian industrial group with multiple active subsidiaries, operating across industrial manufacturing, services, and investment sectors. Its core businesses focus on automotive manufacturing and automotive component production, supported by a solid industrial foundation and strong market recognition in Iran.

Within its automotive components division, the group places strong emphasis on the local production of key electromechanical parts and continues to upgrade its manufacturing facilities toward automation, standardization, and scalable mass production, ensuring long-term and sustainable development of its automotive business.

Project Background & Challenges

As market requirements for product consistency, delivery efficiency, and quality traceability continued to rise, the customer began to face limitations in its existing window regulator motor production:

High dependence on manual assembly, leading to inconsistent product quality

Limited production capacity, restricting output growth

Low efficiency in model changeover for multi-variant production

Lack of a complete production data and quality traceability system

The customer sought a reliable, mature, and long-term automated assembly solution to upgrade its window motor manufacturing capability comprehensively.

Solution Provided by Honest Automation

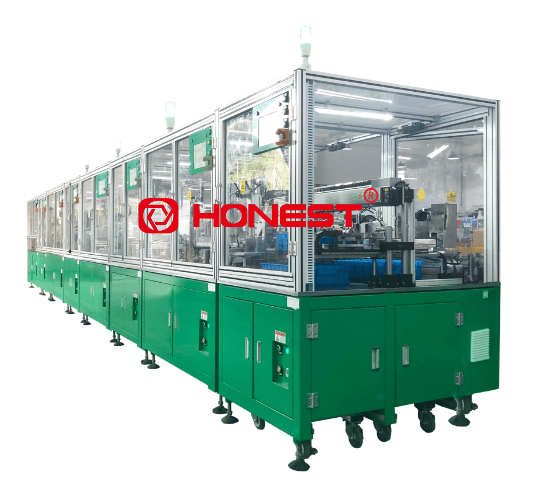

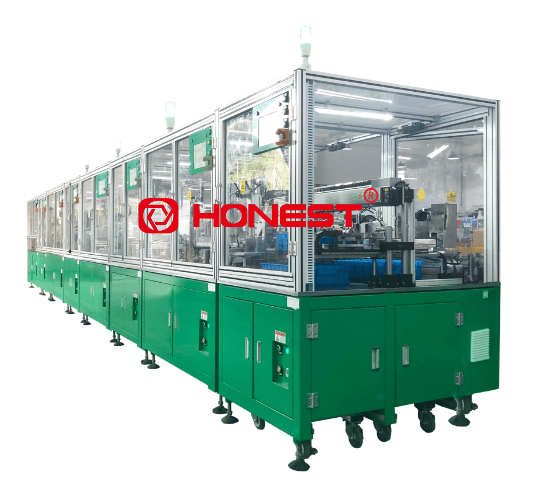

In response to these requirements, Honest Automation delivered a customized automated assembly line for automotive window regulator DC brushed motors, providing a complete one-stop manufacturing solution.

The production line covers the full assembly process from the motor body to the gearbox motor assembly. With an automation-first design supported by manual operations, the solution ensures high efficiency, stable quality, and operational flexibility, establishing a robust core production line for the customer.

Key Equipment Features

Modular and Flexible Line Design

The line supports multiple window regulator gearbox motor variants, including left- and right-hand versions, with fast model changeover through parameter-based recipes.

High Efficiency and Stable Output

A combination of conveyor-based flow lines and standalone stations enables short cycle times and consistent mass production.

Intelligent Control and Centralized Management

The industrial control system enables recipe management, production planning, real-time monitoring, and historical data review, improving overall operational efficiency.

Product Traceability System

Product identification is linked with key production and testing data, supporting quality analysis and continuous improvement.

Performance & Results

After commissioning, the production line has been operating stably with strong performance indicators:

Cycle time: ≤10 seconds

Compatible products: 3 gearbox motor variants (left/right versions supported)

Changeover time: <20 minutes

Yield rate: ≥99%

Overall line utilization: ≥90%

Manpower requirement: Approximately 10 operators for full line operation

This production line was fully assembled and thoroughly tested in our workshop before shipment. Once installed at the customer's facility, it can be quickly commissioned and put into stable mass production.

Why Honest Automation

The customer selected Honest Automation not only for the equipment itself, but also for its comprehensive capabilities:

Proven experience in automotive motor automation and assembly solutions.

One-stop service from solution design to on-site delivery.

Line design focused on stability, maintainability, and overseas project adaptability.

The customer visited our factory and held in-depth technical discussions with our engineering team. After giving very positive feedback, they finalized the price negotiations and signed the contract before returning to Iran.

Application & Scalability

This automated window regulator motor assembly solution offers strong scalability and replicability, making it suitable for:

Automotive window regulator motors and similar DC brushed motor applications.

Automotive component manufacturers are seeking higher automation and stable mass production.

Localization projects in the Middle East and other emerging automotive markets.

Finally, our commissioning team traveled to the customer's site to complete installation, carry out on-site commissioning, and train the customer's operators. The production line has been running smoothly, and the customer expressed high satisfaction, warmly hosting our team during their stay.

Our customers' recognition and praise are the driving force behind our continuous progress.