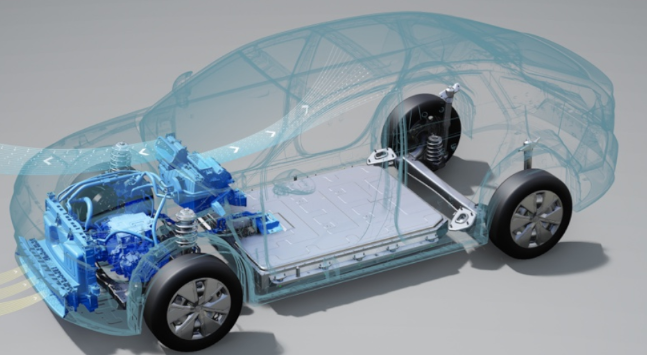

The thermal management system of a vehicle is an essential system for regulating the cabin environment and the working conditions of automotive components, enhancing energy utilization efficiency through a combination of cooling, heating, and internal heat transfer. Within the system, the heat pump is an efficient energy conversion device, primarily utilized in new energy vehicles to improve energy utilization efficiency and passenger comfort.

Heat pump is a highly efficient energy-saving device that fully utilizes low-grade thermal energy. Heat can be transferred spontaneously from a high-temperature object to a low-temperature object, but not spontaneously in the opposite direction.

The heat pump system absorbs heat from the external environment and transfers it to the interior of the vehicle to achieve the heating function. Compared to traditional heating methods, the heat pump system can significantly reduce energy consumption and extend the driving range of electric vehicles.

1. Key Component of a Heat Pump System

Electric Compressor: It is responsible for compressing the refrigerant, thereby increasing its temperature and pressure.

Evaporator: The refrigerant absorbs heat from the external environment in the evaporator, achieving the heating process.

Condenser: The high-temperature, high-pressure refrigerant releases heat in the condenser, heating the interior of the vehicle.

Expansion Valve: It controls the flow rate of the refrigerant to adapt to different thermal load requirements.

Heat Exchanger: It facilitates heat transfer between the refrigerant and air or water.

Electronic Control Unit (ECU): It provides intelligent control over the entire heat pump system to achieve the best energy efficiency ratio and comfort.

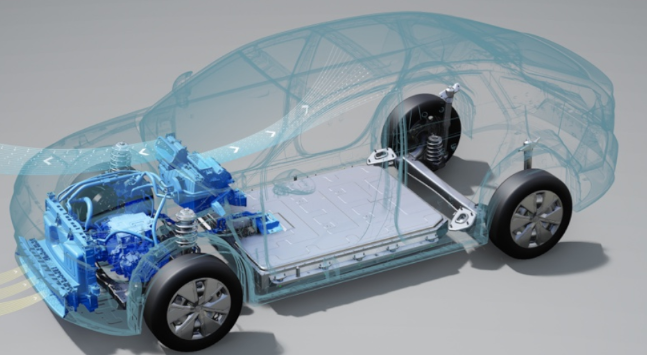

2. Working Principle of a Heat Pump System

The technical principle of a heat pump mainly involves the following key steps:

Evaporation Process: In the automotive heat pump system, the refrigerant absorbs heat from the external environment in the evaporator, evaporating into a gaseous state. The process lowers the temperature of the surrounding environment while absorbing heat.

Compression Process: The gaseous refrigerant is drawn into and compressed by the compressor, during which both the temperature and pressure of the refrigerant increase.

Condensation Process: The compressed high-temperature, high-pressure refrigerant enters the condenser, where it releases heat, heating the interior of the car or used for heating the battery pack. The condensation process causes the refrigerant to change from a gaseous state to a high-pressure liquid state.

Expansion Process: The high-pressure liquid refrigerant, after passing through the expansion valve, experiences a drop in pressure and a corresponding decrease in temperature, then returns to the evaporator for the next cycle.

Four-way Valve: The automotive heat pump system usually includes a four-way valve, used to switch between cooling and heating modes. In cooling mode, the four-way valve adjusts the direction of the refrigerant flow to the conventional air conditioning cooling cycle; in heating mode, the four-way valve changes the flow direction, causing the original evaporator to act as a condenser and the condenser to act as an evaporator, achieving the heating function.

Electronic Control Unit: The entire heat pump system is intelligently controlled by the ECU to adapt to different driving conditions and the comfort needs of passengers.

Auxiliary Heating: In extremely low-temperature environments, the heat pump system may require auxiliary heating elements to provide additional heat to ensure the comfort of passengers inside the vehicle.

Integrated Design: The automotive heat pump system is usually designed in an integrated manner with other thermal management components of the vehicle to achieve optimal energy utilization and distribution.

3. Advantages of the Heat Pump System

The heat pump system in the automotive thermal management system has the following advantages compared to traditional heating systems (such as resistive heaters or PTC heaters):

High Energy Efficiency: The heat pump system absorbs heat from the external environment and transfers it to the interior of the vehicle, rather than directly converting electrical energy into heat. This means it can produce more heat with less electrical energy, thus improving energy efficiency.

Energy Saving: Due to the high energy efficiency of the heat pump system, it can significantly reduce energy consumption and extend the range of electric vehicle batteries.

Environmentally Friendly: The heat pump system reduces reliance on electrical energy, which helps to reduce greenhouse gas emissions and aligns with the current automotive industry’s pursuit of environmental protection and sustainable development.

Comfort: The heat pump system can provide a more uniform and stable heating effect, improving the comfort of the ride.

Multifunctionality: Modern automotive heat pump systems can not only be used to heat the interior space but can also be combined with the battery cooling system to use waste heat to heat or cool the battery, improving battery performance and lifespan.

Intelligent Control: The heat pump system is usually equipped with an advanced electronic control unit that can intelligently adjust the working state according to the actual needs of the vehicle and external environmental conditions, optimizing energy use.

Strong Adaptability: The heat pump system can operate over a wide temperature range, including providing effective heating in low-temperature environments, making it very suitable for use under different climatic conditions.

Reduced Dependence: In some vehicle models, the heat pump system can reduce the dependence on engine waste heat, which means that the vehicle can provide heating even when the engine is off.

Low Maintenance Cost: The heat pump system has fewer components and operates at lower pressures and temperatures, so the maintenance cost is relatively low.

System Integration: The heat pump system can be integrated with other vehicle systems, such as the air conditioning system and the battery management system, to achieve more efficient energy management and vehicle performance optimization.

4. Functions of the Heat Pump System

Interior Heating: One of the main functions of the heat pump system is to provide heating for the interior of the vehicle to maintain comfort during winter travel.

Improved Energy Efficiency: The heat pump system heats the interior by absorbing heat from the external environment, which allows it to produce more heat with lower energy consumption compared to direct resistive heating, thereby improving energy efficiency.

Extending the Range of Electric Vehicles: Since the heat pump system reduces the consumption of battery energy, it helps to extend the range of electric vehicles.

Battery Temperature Management: The heat pump system can be integrated with the battery cooling system to provide necessary heating or cooling for the battery to maintain it within the optimal working temperature range, thus improving battery performance and lifespan.

Intelligent Control: Modern automotive heat pump systems are usually equipped with intelligent control units that can automatically adjust the working state according to the vehicle’s real-time needs and external environmental conditions, optimizing energy use and passenger comfort.

5. Challenges Faced by the Heat Pump System

Performance in Low-Temperature Environments: Under extremely low-temperature conditions, the efficiency of the heat pump system in absorbing heat from the external environment decreases, so additional auxiliary heating is needed to ensure the temperature inside the vehicle.

System Integration and Control Complexity: As the complexity of the thermal management system in new energy vehicles increases, the heat pump system needs to work in conjunction with multiple subsystems such as the battery cooling system and the motor and electronic control cooling system, which increases the difficulty of system integration and control.

Choice of Refrigerant: Environmental regulations have strict requirements for the global warming potential of refrigerants, and the heat pump system needs to use refrigerants with low GWP, which may affect system performance and cost.

6. Development Trend Forecast for Heat Pump Systems

Market Size Growth: With the rapid development of the new energy automotive industry, heat pump systems, as an important technology to improve the energy efficiency and range of electric vehicles, are experiencing a rapid increase in market demand.

Technological Advancement and Innovation: Heat pump system technology will continue to evolve and innovate to address issues such as high heating energy consumption and insufficient capacity.

Cost Control: As technology matures and production scales up, the cost of heat pump systems is expected to decrease further, thereby increasing popularity in new energy vehicles.

System Integration: There is a trend towards integrating heat pump systems with other automotive thermal management components to achieve more efficient energy management and vehicle performance optimization, such as battery cooling systems and motor and electronic control cooling systems.

Policy Support: Governments around the world are providing policy support and subsidies for new energy vehicles and their key technologies, such as heat pump systems, which will drive the rapid development of heat pump technology.

7. About HONEST

HONEST is deeply engaged in the manufacturing and assembly of intelligent motor equipment, committed to providing innovative and efficient intelligent motor equipment solutions for the automotive, auto parts, and motor manufacturing industries, helping them achieve high-quality and efficient production. If you have any needs, please feel free to contact us.