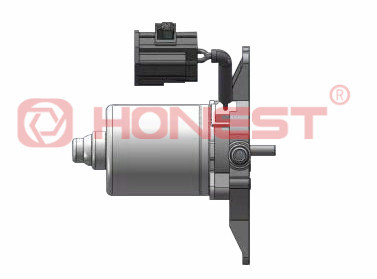

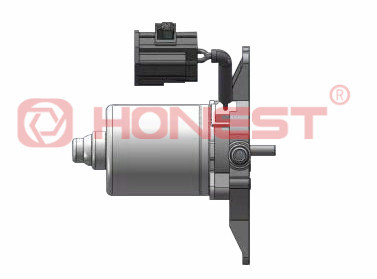

ABS (Anti-lock Braking System) is an automobile brake anti-lock braking system motor and is a key component in the modern automobile braking system.

The working principle of ABS pump motor:

The working principle of the ABS motor is based on advanced electronic control technology, which achieves real-time monitoring and adjustment of the vehicle’s braking force through precise sensors and computer algorithms.

According to the working process of the ABS motor, the working principle of the ABS motor is introduced:

1. ABS motor receives a signal:

When the car driver presses the brake pedal, the sensor monitors the wheel speed in real time. If the speed of a wheel drops too quickly, the sensor immediately sends a signal to the electronic control unit(EUC). The EUC analyzes these signals through computer algorithms and determines whether the braking force of the wheel needs to be adjusted.

2. When the ABS motor starts working:

When the EUC determines that the braking force needs to be adjusted, it activates the ABS motor. The ABS motor controls the braking force by regulating the flow of brake fluid. The ABS motor opens or closes the passage of brake fluid to the wheels, thereby adjusting the amount of braking pressure. By precisely controlling the flow of brake fluid, the ABS motor prevents the wheels from locking and keeps them within the range for optimal braking effect.

The function of the ABS pump motor:

The role of the ABS pump motor is to supply power to the ABS pump to help it play a role in avoiding the loss of control of the vehicle, increase the braking distance, improve vehicle safety, and improve the braking performance of the vehicle. The function of the ABS brake master cylinder is to improve dynamic performance, improve driving safety, avoid wheel locking during braking, and avoid lateral slipping during emergency braking of the vehicle.

The working advantages of ABS motor:

1. The ABS motor adjusts the braking force with high stability

ABS motor can quickly adjust the braking force to adapt to the changes in different road conditions and driving conditions. In the case of emergency braking or a road surface steep slope, compared with the traditional braking system, the ABS motor can more accurately control the braking force, and provide a better braking effect, to avoid excessive braking caused by wheel slip.

2. ABS motor works with shorter braking distance and high safety

The role of the ABS motor in the automotive braking system is not only to improve braking performance and stability but also can greatly reduce the braking distance when braking. When the wheels are clutched, the car will lose directional control, and it is difficult to keep on the driver’s expected path. The application of ABS motors can greatly reduce such risks, allowing the car to maintain good handling when braking, and improving the safety of driving.

The working precautions of ABS motor:

1. Perform regular maintenance on ABS motors

Regular maintenance of the working condition of the ABS motor is crucial. Checking the level and quality of the brake fluid and determining the accuracy and sensitivity of the sensor can ensure that the ABS motor can work properly and maintain a good braking effect.

2. Use correct braking techniques when driving a car

Drivers should also pay attention to correct braking techniques when using ABS motors. Although the ABS can provide better braking performance, it is still recommended that the driver maintain a stable pedal force when braking and avoid excessive depression of the brake pedal. Proper use of the braking system can not only extend the life of the braking system but also improve overall driving comfort and safety.

The ABS motor is an important part of modern automobile braking systems. By understanding the working principle of ABS motors, rational use, and regular maintenance of ABS motors, we can ensure the normal operation of automobile ABS motors and provide reliable braking effect, thereby improving driving safety and comfort.

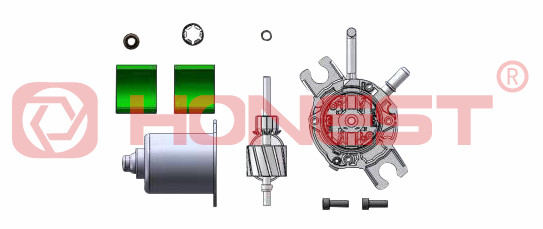

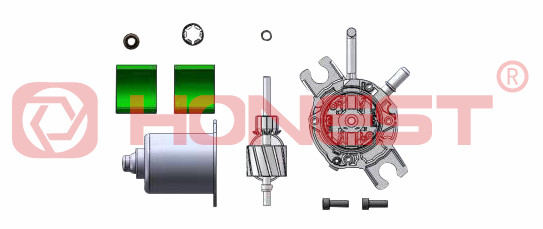

The advantages of HONEST Automation’s ABS Brake Motor Assembly Line

1. It is suitable for automotive motor engine systems;

2. Integration of QR code printing, labeling, and scanning functions;

3. Full process data collection, monitoring, and storage;

4. High flexibility and automation;

5. The entire line requires 2 people to load and unload materials;

6. It can perform non-standard customization.

The market forecast for ABS motor:

Overall Market Trends:

The global ABS motor market is expected to reach 12 billion dollars in 2024, a year-on-year increase of 10%. The main growth driver comes from the continued development of the automotive industry, especially the rapid growth of new energy vehicles. The Asia-Pacific region will be the main growth area for the ABS motor market, which is expected to reach 6 billion dollars in 2024, accounting for 50% of the global market share.

Market Forecast by Region:

North America: the North American ABS motor is expected to reach 2.5 billion dollars in 2024, a year-on-year growth of 8%;

Europe: the European ABS motor market is expected to reach 2 billion dollars in 2024, a year-on-year growth of 9%;

Asia-Pacific: the Asia-Pacific ABS motor market is expected to reach 6 billion dollars in 2024, a year-on-year growth of 12%;

China: China’s ABS motor market is expected to reach 3.5 billion dollars in 2024, a year-on-year growth of 15%.

Other regions: the ABS motor market in other regions is expected to reach 1.5 billion dollars in 2024, a year-on-year growth of 10%.

If you have any interest in ABS motor production line, please contact us at your time.