The Definition of the Brushed Motor

The brush motor is a rotating electrical machine that contains a brush device to convert electrical energy into mechanical energy (motor) or mechanical energy into electrical energy (generator). The brush motor is the basis of all motors. It has the characteristics of fast starting, timely braking, smooth speed regulation in a wide range, and a relatively simple control circuit.

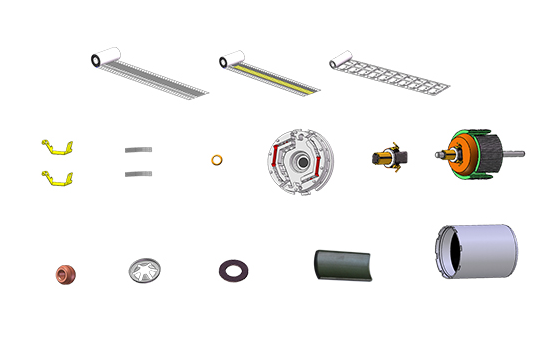

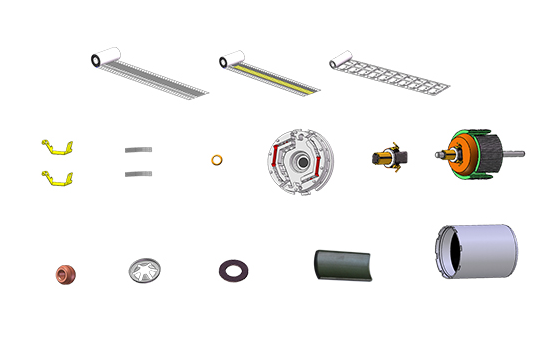

The structure of the Brushed Motor

1. Stator: it is the stationary part of the motor, consisting of magnetic poles and coils;

2. Rotor: it is the rotating part of the motor;

3. Brush: it is the conductive part of the motor that contacts the commutator and transfers current to the rotor winding;

4. Commutator: it is the rotating conductive part of the motor that contacts the brushes and switches the direction of the current.

Brushed motors have several advantages:

Simple design: They are relatively simple to design and manufacture, making them less expensive than other types of motors.

High starting torque: They can generate a lot of torque at low speeds, making them ideal for applications like power tools and starter motors.

Wide speed range: They can be easily controlled to operate at a wide range of speeds.

Brushed motors also have some disadvantages:

Low efficiency: The friction between the brushes and the commutator generates heat, which reduces the motor's efficiency.

Short lifespan: The brushes and commutator wear out over time, requiring regular maintenance or replacement.

Sparkling: The sparking at the brushes can create electromagnetic interference and can also be a fire hazard in some environments.

The Market Forecast of Brushed Motor

According to predictions from relevant market research, the global brush motor market will reach 10 billion dollars in 2024, a year-on-year increase of 15%. Among them, China, the United States, and Europe will be the main growth drivers of the global brush motor market.

China

China is the world’s largest brush motor market and the main application field of brush motors. With the rapid development of China’s economy, the demand for brushed motors will maintain strong growth. It is expected that China’s brush motor market will reach 4 billion dollars in 2024, a year-on-year increase of 20%.

USA

The U.S. government has also introduced several policies to support the development of brushed motors, which will provide a good policy environment for the brushed motor market. In addition, the growing demand for high-performance brushed motors in the U.S. market is also providing impetus to the market growth. The U.S. brush motor market is expected to reach 2 billion dollars in 2024, a year-on-year growth of 10%.

Europe

The European government has higher requirements for the safety and reliability of brushed motors, which will drive brushed motor companies to continuously improve their product technology and quality. The European brush motor market is expected to reach 2 billion dollars in 2024, a year-on-year growth of 10%.

The markets in Asian countries and regions such as Japan and South Korea will also maintain growth momentum. The economies of these countries and regions are developing rapidly, and the demand for brushed motors will continue to grow. It is expected that the market size of Japan, South Korea, and other Asian countries and regions will reach 2 billion dollars in 2024, a year-on-year increase of 5%.

Overall, the global brush motor market will show a steady and rising trend in 2024. With the development of the economy, technological progress, and expansion of application fields, the brush motor market will usher in a broader development space.

Brushed Motor Assembly Line

A. Automobile Electric Sunroof Motor Assembly Line

The original design of the automobile electric sunroof motor assembly line is based on automatic equipment and supplemented by manual operations. It is a line with a relatively high degree of automation and guaranteed product quality. The entire line includes stator loading and magnetizing, motor assembly, motor running-in test, magnetic ring worm assembly, gearbox assembly, gear back cover assembly, performance testing, laser marking, vibration testing, and other processes. It is an automated production and assembly line for brush motors and gearboxes, which provides a one-stop solution for the production of automobile electric sunroof motors.

B. Motor Automation Production Line

The motor automation production line is used for the assembly and production of electric tailgate motors in automobiles. The equipment consists of three main parts: the rotor assembly section, magnetic bottom assembly section, and motor assembly section, which are its core components. The modular and flexible design of the equipment also makes the motor automation production line more flexible, with a wide range of product compatibility. Its equipment can be compatible with the assembly and production of 14 types of motors, greatly reducing the production replacement cost of the enterprise.

Equipment Parameters

Production Efficiency: 3.6s/pcs;

Compatible Products: 14;

Exchange Time: <30minutes;

Voltage: AC220V/380V 50HZ;

Air Pressure: 0.4-0.6MPa;

Yield Rate: ≥99%;

Utilization Rate: ≥90%;

Power: 100KW;

Appearance Size: U-shaped layout: 28000(L)*7500(W)*2000(H)mm.

If you need a solution for automotive brush motor assembly line automation equipment, please consult us online to get a customized solution and quotation.