With the rapid development of the Electric vehicle industry, the demand for the performance of drive motors is increasingly high. Hairpin motors, due to their outstanding performance and innovative design, are gradually replacing traditional roundwire motors to become the core of drive technology in Electric vehicles. The article will delve into the manufacturing processes, characteristics, and application scenarios of hairpin motors in the automotive field.

Introduction to Hairpin Motors

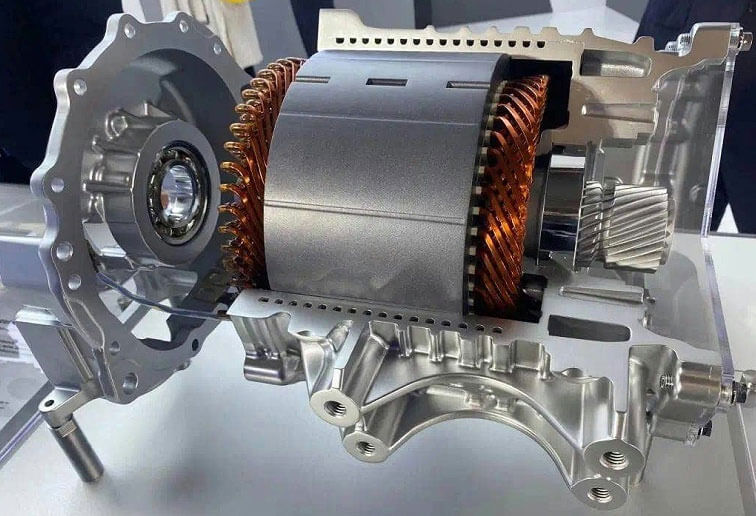

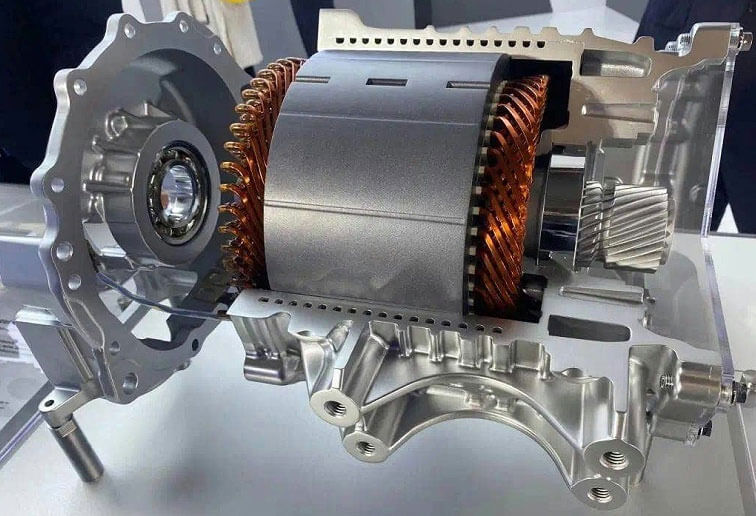

Hairpin motor are a type of motor that generates force and motion by utilizing the movement of coils within a magnetic field. Their manufacturing process includes flat wire forming, winding, welding, and insulation treatment, with the winding process being the crucial step that determines their performance.

Flat Wire Forming: Copper wires are processed into a flat shape and undergo insulation treatment to create enameled flat wires.

Winding Process: The winding of flat wires is carried out using axial insertion or radial embedding methods.

Welding Technology: The ends of the flat wires must be connected through welding technology to form a closed circuit. The quality of the welding directly affects the motor's stability and lifespan.

Insulation Treatment: Advanced insulation materials and techniques are employed to ensure the safety and reliability of the motor under high voltage conditions.

.jpg)

Hairpin motors possess the following characteristics compared to traditional round wire motors:

Advantages:

1.High Slot Fill Factor: The slot fill factor of hairpin motors typically exceeds 70%, significantly higher than the 40-50% of traditional round wire motors. A higher slot fill factor means that more copper conductors can be packed into the stator slots, resulting in a stronger rotating magnetic field. This implies that hairpin motors can accommodate more copper wires within the same motor volume, thereby enhancing the motor's power density and efficiency.

2.Low Losses: Hairpin motors exhibit lower resistive losses because the resistance of flat conductors is smaller than that of round wires with the same cross-sectional area. Additionally, the increased slot fill factor also reduces magnetic reluctance losses.

3.Excellent Heat Dissipation: Compared to round wires, the regular shape of flat wires allows for closer contact between each copper wire, providing a larger heat dissipation surface area, which helps to dissipate heat more effectively, improving the motor's thermal stability and lifespan.

4.Compact Structure: Due to the high slot fill factor, hairpin motors can achieve the same power output within a smaller volume, contributing to the reduction of the overall vehicle weight and improving the utilization of space.

Hairpin motors also have their disadvantages:

1.Increased losses due to the skin effect. The skin effect refers to the uneven distribution of current within a conductor when there is an alternating electromagnetic field, with the current concentrating in the "skin" of the conductor and less current in the interior. This results in an increased resistance of the conductor, thereby increasing its power loss.

2.High requirements for copper wire: Thicker copper materials have a certain degree of elasticity, which causes some rebound after bending, increasing the design difficulty. At the same time, the insulation layer of the copper wire is also more susceptible to damage and chipping due to bending and rebound.

Only by accurately understanding the advantages and disadvantages of hairpin motors can they be better utilized in actual production.

Application scenarios of hairpin motors in the Electric vehicle industry

With the development and popularization of hairpin motor technology, many car manufacturers, such as Tesla and BYD, have also begun to gradually apply flat wire motors. The specific application scenarios in the electric vehicle industry are as follows:

1.Drive motors: With their high efficiency, high power density, excellent heat dissipation, and smaller size and weight, hairpin motors have become an ideal choice for the drive motors of electric vehicles. This allows vehicles to provide higher power and efficiency within a limited space while reducing energy consumption and improving driving range.

2.Auxiliary system motors: hairpin motors are also used in auxiliary systems of electric vehicles, such as electronic steering systems and electric air conditioning compressors. These auxiliary systems can benefit from the high power density and low loss characteristics of hairpin motors.

3.800V high-voltage platform: As users' demands for driving range and charging speed of electric vehicles increase, the 800V high-voltage platform is gradually becoming a new trend. Hairpin motors need to have higher voltage resistance and better heat dissipation performance to ensure the safety and reliability of the motor.

The Advantages of Hairpin Motors in the Electric Vehicle Field are Reflected in:

1.Enhancing Vehicle Performance: The high power density and high efficiency of hairpin motors can significantly improve the acceleration performance, climbing ability, and driving range of electric vehicles.

2.Improving Driving Experience: The low noise and low vibration characteristics of hairpin motors can provide a more comfortable and quiet driving experience for drivers.

3.Reducing Motor Size: At the same power, hairpin motors have a smaller size, which can provide more freedom for vehicle design.

4.Enhancing Motor Reliability: The excellent insulation and heat dissipation performance of hairpin motors can effectively extend the service life of the motor.

According to relevant data forecasts, the penetration rate of hairpin motors in automotive drive motors will continue to increase.

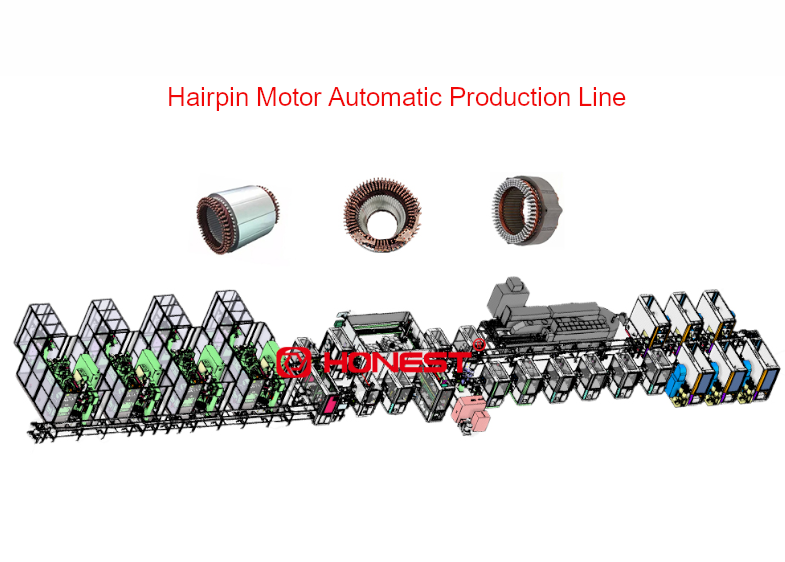

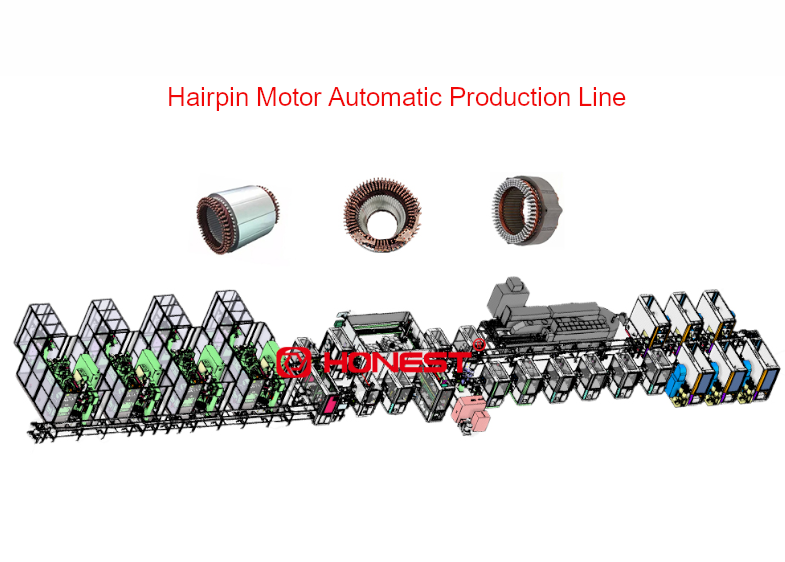

Hairpin motor, with their high efficiency, high power density, and excellent heat dissipation performance, have shown great advantages in the electric vehicle field. With the continuous development and innovation of technology and the expansion of market scale, it is expected that by 2025, the market penetration rate of hairpin motors will break through 90%, becoming the mainstream technology for drive motors and promoting the automotive industry to develop towards a more efficient and energy-saving and environmentally friendly direction. If you need hairpin motor production equipment, please feel free to contact HONEST, and we will provide you with a detailed equipment introduction and preliminary quotations.

.jpg)