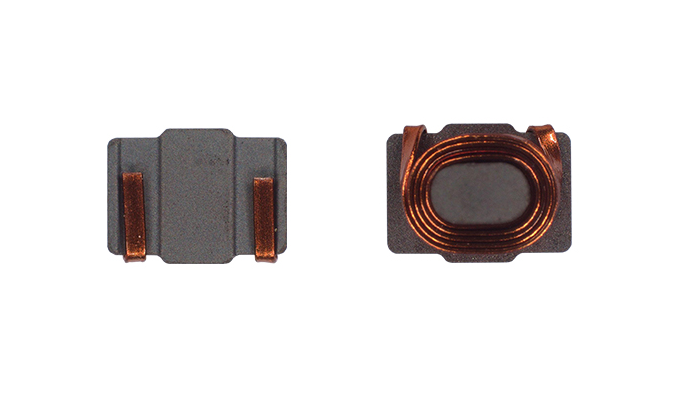

The inductor is a kind of attribute to close the circuit. When the current is through the coil, the magnetic field induction is formed in the coil. The induced magnetic field, in turn, produces an induced current that opposes the flow of current through the coil. The inductor is a circuit parameter that describes the effect of induced electromotive force caused by changes in coil current within the same coil or in another coil. It is a collective term for self-inductance and mutual inductance, and the device that provides inductance is known as an inductor. The inductor winding machine is an important piece of automated equipment in industrial manufacturing, and its performance directly affects the performance and quality of inductive components.

A.The Function of the Inductor - Allows DC, Blocks AC

Inductors primarily serve to filter, oscillate, delay, and trap waves in circuits, as well as to select signals, filter noise, stabilize currents, and suppress electromagnetic interference.

In electronic circuits, inductive coils have a current-limiting effect on AC. They can form high-pass or low-pass filters, phase-shifting circuits, and resonant circuits in conjunction with resistors or capacitors. Transformers can perform AC coupling, voltage transformation, current transformation, and impedance transformation, among other functions.

B.Working Principle of Inductor Winding Machine

The inductor winding machine is a device used for manufacturing inductors, operating on the principle of electromagnetic induction to achieve the winding of coils.

The inductor winding machine mainly consists of the frame, coil supply device, coil winding mechanism, and control system. The specific working principle is as follows:

1.Coil Supply Position: In the inductor winding machine, the coil supply device is used to provide the wire material required for coil winding. The wire material is typically made of conductive materials such as copper or aluminum wires. The coil supply device controls the supply speed and tension of the wire material to ensure the quality and stability of the coil winding.

2.Coil Winding Mechanism: The coil winding mechanism is the core part of the inductor winding machine, which controls the winding speed and direction of the coil to achieve coil winding. During the winding process, the coil winding mechanism, according to preset parameters, sequentially winds the wire material around the winding axis to form the required coil structure. During the winding process, the inductor winding machine automatically adjusts the winding speed and direction according to the size and shape of the coil to ensure the quality and accuracy of the coil.

3.Control System: The control system is the core of the inductor winding machine, which precisely controls the entire winding process by controlling the coil supply device and the coil winding mechanism. The control system can automatically adjust the winding speed, direction, and tension of the coil according to preset parameters to achieve the ideal winding effect of the coil. At the same time, the control system can also monitor the process parameters during the winding process, such as the tension of the wire material and the size of the coil, to ensure the stability and consistency of the winding quality.

The Inductor Winding Machine Plays a Crucial Role in the Manufacture of Inductors, Enhancing Production Efficiency and Quality Stability.

The core components of the inductor winding machine are composed of the following parts, which together ensure the efficiency of the production process and the quality of the final product, the details are as follows:

1.Wire Feeding Mechanism: Responsible for delivering the conductor from the wire spool and maintaining a stable wire feeding speed through a tension control system to prevent the coil from being too loose or too tight.

2.Winding Head: The key component that realizes the winding action, driven by a stepper motor or servo motor, ensuring rotation according to the preset number of turns and spacing to complete uniform and precise coil winding.

3.Tension Control System: Stabilizing the tension of the conductor is extremely important for the quality of winding. The tension control system adjusts in real-time to ensure the density and consistency of the coil.

4.Stepper or Servo Motor: Provides precise rotational control to achieve high-precision winding and ensure the reliability of the winding process.

5.Control System: Integrated with PLCs, touch screens, etc., to achieve automated control of the entire winding process.

6.Transmission System: It converts the rotational movement of the motor into the precise linear movement of the winding head. The accuracy of this conversion process directly affects the winding effect and the quality of the coil.

7.Detection System: Including photoelectric sensors, encoders, etc., used to detect key parameters such as the size and number of turns of the coil to ensure that the product quality meets the standards.

C.Application Scenarios of the Inductor Winding Machine:

1.Motor Manufacturing: The inductor automatic winding machine can be used to manufacture various motors, including motors in household appliances such as vacuum cleaners, mixers, etc., as well as large industrial motors. In these types of motors, the inductor coil is a key part of generating the magnetic field.

2.Transformer and Ballast Production: The inductor automatic winding machine can also be used to manufacture transformers and ballasts. These devices are used to adjust voltage and current, protect circuits and equipment, and play an important role in the power system.

3.Automotive and Aerospace Manufacturing: In the automotive and aerospace fields, the inductor winding machine can be used to manufacture ignition coils, generators, etc., in automobiles, as well as high-precision inductor coils in aerospace equipment.

In all, the inductor automatic winding machine has a wide range of applications in the production of electrical and electronic products and is an important equipment in the manufacturing industry. Therefore, choosing the right equipment supplier is also a key part. HONEST Automation will be your reliable partner.

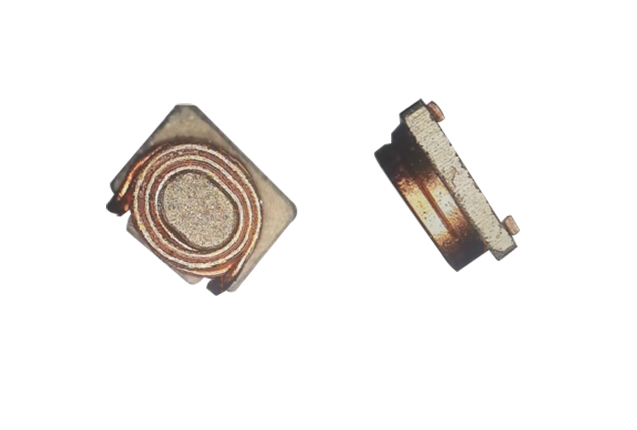

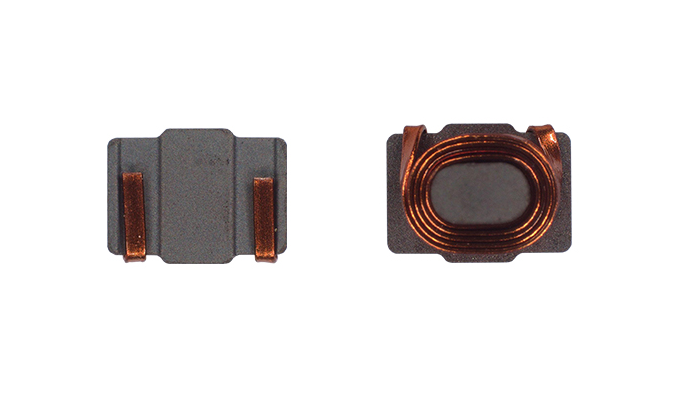

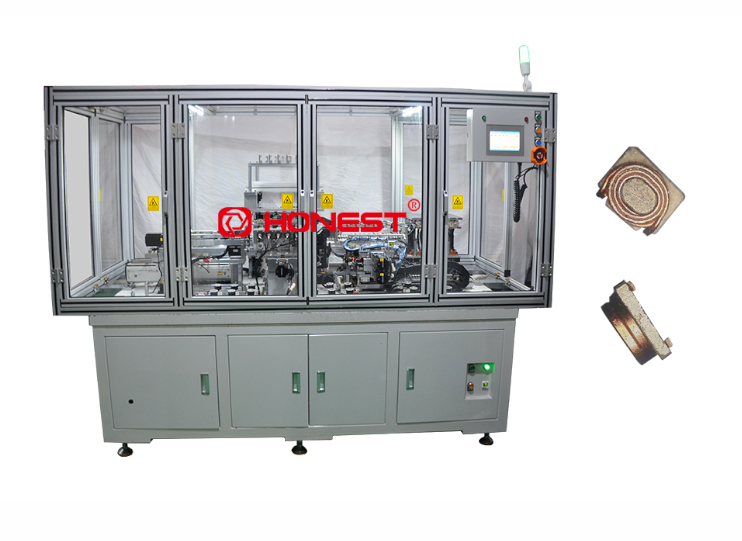

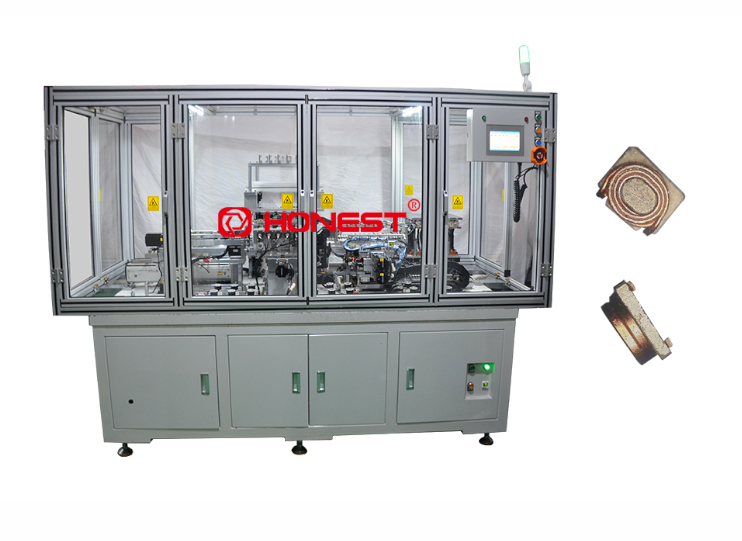

D.HONEST Automation’s Tcore Integrated Inductor Winding Machine

In the field of electronic component manufacturing, our Tcore integrated inductor winding machine has gained customer recognition and choice due to its high efficiency, precision, and reliability. Here are the key advantages of our equipment:

1.High Production Efficiency: With a 6-10 axis winding machine design, production efficiency is enhanced, with each product's winding completed in just 0.3-0.5 seconds.

2.Precise Control: Precise control over the tail length of the wire, keeping it between 7-10mm, reduces waste wire by 50%, optimizes material utilization, and saves material costs.

3.Self-Manufacturing: Key parts of the equipment are manufactured in-house with precision equipment, and life management of key components helps reduce maintenance costs for customers.

4.Complete Process Coverage: The equipment can complete all processes from core loading to winding, straightening, and unloading in one stop, simplifying the production process.

Choosing our Tcore integrated inductor winder, you will get an efficient, reliable, and space-saving inductor winding machine solution, helping you gain an advantage in market competition.

E.Precautions for Using the Inductor Winding Machine

Systematic and correct maintenance and care of the inductor winding machine are key to its long-term stable operation, improving production efficiency, and extending service life. Here are some precautions to take when using the inductor winding machine daily:

1.Pre-operation Inspection: Operators should have the necessary operating skills and safety awareness, and be familiar with the equipment operation steps. Before operation, conduct a comprehensive inspection of the winding machine to ensure there are no faults or abnormalities.

2.Cleaning and Maintenance: After operation, promptly turn off the power and clean the equipment to remove debris and impurities generated during the winding process, ensuring normal operation for the next use.

3.Regular Inspection and Lubrication: Regularly inspect the transmission and lubrication parts of the equipment to ensure normal operation.

4.Professional Skills Training: Provide systematic and comprehensive operation training for staff to avoid damage to the equipment due to improper operation.

By following the above precautions, you can effectively reduce equipment failures, ensure stable operation, and extend the service life of the inductor winding machine. If any issues arise during operation, contact the equipment supplier promptly for professional solutions.

HONEST Automation is committed to providing professional technical support services. When delivering equipment, we not only provide customers with comprehensive one-on-one practical operation and technical training to ensure proficiency in equipment operation but also provide ongoing technical support at every stage of the customer's use of the equipment. If any issues are encountered during use, customers can contact us at any time. Our technical engineers are committed to identifying the problem within 24 hours and proposing corresponding solutions. In addition, to respond more quickly to customer needs and provide technical support for foreign customers, HONEST Automation has established dedicated after-sales technical service sites in countries such as India, ensuring smooth customer production.

If you have a need for an inductor winding machine, please confidently choose HONEST Automation as your supplier. We will be your reliable partner and look forward to hearing from you.