As demand for high-efficiency and compact electric motors continues to rise, manufacturers face increasing pressure to deliver quality at scale. Traditionally, motor winding was a labor-intensive process, relying heavily on skilled technicians. However, the adoption of BLDC motor winding machine is transforming this critical production step by offering faster, more precise, and more reliable solutions.

In this article, we explore the key advantages of using automated brushless motor winding machines compared to manual winding, helping manufacturers make informed decisions as they scale up their operations.

1. What is a BLDC Winding Machine?

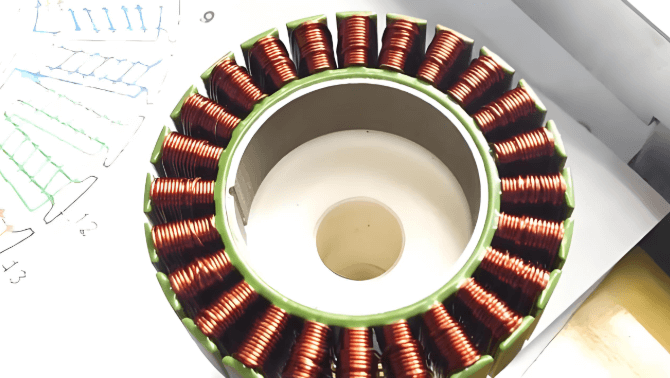

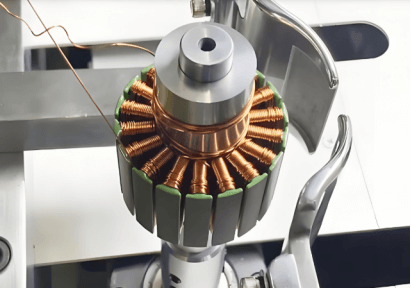

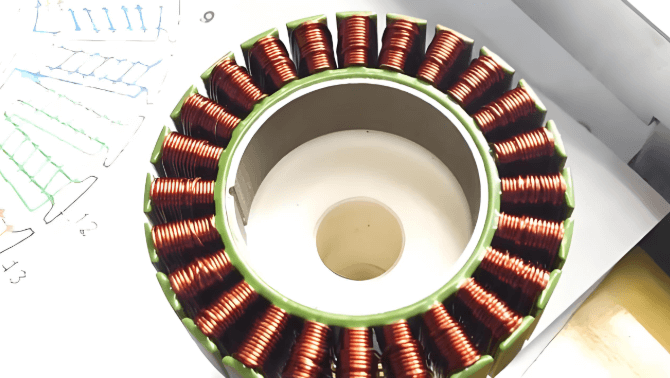

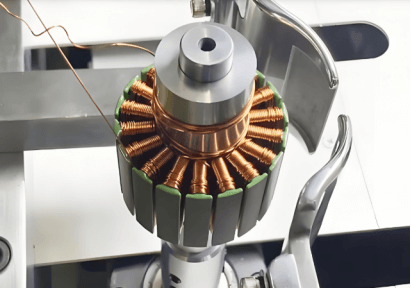

A BLDC winding machine is a specialized piece of equipment designed to automate the coil winding process for BLDC (Brushless DC) motor stators and rotors. These machines are capable of winding fine copper wire into exact patterns and tension, ensuring optimal electrical performance and uniformity across every unit.

Modern winding machines feature programmable logic controllers (PLCs), servo motors, high-resolution wire tensioners, and visual inspection systems to maximize precision and minimize error.

2. Limitations of Manual Winding

Manual winding, though still used in small-batch or prototype production, presents several challenges in mass manufacturing:

Inconsistent Quality: Human error can lead to variations in coil tension, spacing, and alignment.

Low Productivity: Manual winding is time-consuming and requires significant labor hours.

High Rejection Rates: Improperly wound coils may cause motor imbalance, overheating, or failure.

Labor Dependence: Skilled workers are essential, but fatigue and turnover impact output and consistency.

3. Key Advantages of Using Winding Machines

3.1 Precision and Consistency

Winding machines deliver micrometer-level accuracy in coil placement and tension control. Every motor is wound to exact specifications, eliminating variability and improving overall product quality.

3.2 Higher Production Efficiency

Automated machines operate at speeds far beyond manual capabilities, often winding multiple coils simultaneously. This significantly shortens production cycles and increases output.

3.3 Improved Product Quality

Uniform wire distribution enhances the motor’s electromagnetic performance, reducing vibration, noise, and power losses. This leads to longer motor life and higher customer satisfaction.

3.4 Cost Optimization

While the upfront cost of winding machines may be higher, they reduce long-term labor, material waste, and error correction costs. This results in lower total cost of ownership (TCO).

3.5 Flexibility and Customization

Advanced machines allow fast changeovers between different motor models. Operators can quickly adjust programs or replace tooling for new motor sizes or configurations.

3.6 Data Integration and Quality Monitoring

Many modern winding machines come with integrated sensors and software to track production data in real time. Manufacturers gain traceability and early warning of defects.

4. Case Study: Production Line Comparison

Scenario:

A motor manufacturer producing 20,000 automotive fan motors per month transitioned from manual winding to a dual-station BLDC winding machine.

Results:

Production Efficiency: Increased by 3x

Rejection Rate: Reduced from 5% to <0.5%

Labor: Cut from 6 operators to 2 machine attendants

Payback Period: Reached ROI in 9 months

This real-world shift underscores the long-term benefits of automation, especially for manufacturers focused on consistent quality and scale.

5. Application Areas of Automated Winding

Brushless motor winding machines are used across multiple industries:

Automotive: EPS motors, cooling fan motors, oil pump motors, and traction motors

Robotics and Drones: High-efficiency motors for actuators and propulsion

Medical Devices: Precision motors in imaging and diagnostic equipment

Home Appliances: Vacuum cleaners, washing machines, and HVAC systems

6. How to Choose the Right Brushless Motor Winding Machine

When selecting a winding machine, consider:

Motor Type: Inner vs. outer rotor, slot type, number of poles

Wire Specifications: Diameter, coating, and insulation requirements

Production Volume: Daily/weekly output needs

Flexibility: Does it support multiple SKUs or motor models?

After-Sales Support: Local installation, training, and service availability

Partnering with a reliable equipment supplier who understands your product requirements can significantly ease the transition and ensure long-term performance.

Automated brushless motor winding machines offer unmatched precision, speed, and scalability compared to manual winding. For manufacturers looking to improve product quality, reduce cost, and enhance production capabilities, investing in modern winding technology is not just an upgrade—it’s a competitive necessity.

As the global demand for high-performance motors continues to grow, automation will be key to staying ahead.

7. FAQs

Q: What types of motors can use the BLDC motor winding machine?

A: They are suitable for BLDC stator, PMSM stator, slot-less motor, outer rotor, and customized multi-slot configurations.

Q: Is manual winding still viable for small batch production?

A: Yes, for prototyping or ultra-low volume production, manual winding is still useful. However, consistency and speed are limited.

Q: What is the ROI period for investing in a winding machine?

A: Typically 6–12 months, depending on production scale and model complexity.

8. Leading BLDC Motor Winding Machine Manufacturer

HONEST Automation is a leading manufacturer and solution provider of BLDC motor winding machines. We offer a wide range of BLDC winding equipment—from semi-automatic to fully automatic systems—designed to meet the diverse production needs of industries such as automotive, medical devices, humanoid robotics, power tools, and home appliances. Contact us today to learn more about our customized solutions.

HONEST Automation has a global business presence, with sales offices and localized after-sales service teams in countries including India, Malaysia, Brazil, Argentina, Vietnam, the United States, South Korea, and Russia. Our local teams ensure timely communication and fast response to customer needs, providing efficient support and solutions across different regions.