Key Technical Challenges in W-Pin Motor Winding Process

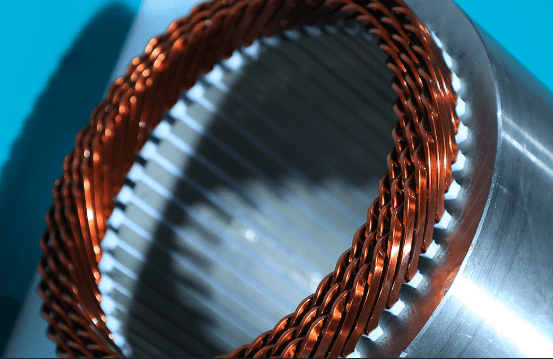

Winding Forming Technology

High Precision Requirements for Wire Diameter

W-pin motor winding commonly uses flat wire, making precise control of wire diameter critical. If the wire diameter is too thick, it becomes difficult to accurately insert the winding into the stator slots, resulting in poor fit and potential mechanical interference. Conversely, a wire diameter that is too thin can compromise the mechanical strength and electrical conductivity of the winding, negatively impacting motor stability and lifespan. Therefore, wire diameter tolerances directly affect the forming quality and overall motor performance.

Stability Challenges in Continuous Forming

During the continuous winding and forming process, maintaining consistent parameters such as wire tension, bending angles, and twist head positioning is essential. Even slight deviations can cause irregular coil geometry, leading to deformation, looseness, or stress concentrations in the winding. These defects may degrade the motor’s electromagnetic performance and assembly precision. Achieving efficient and stable continuous forming is crucial to enhancing production automation and ensuring consistent product quality.

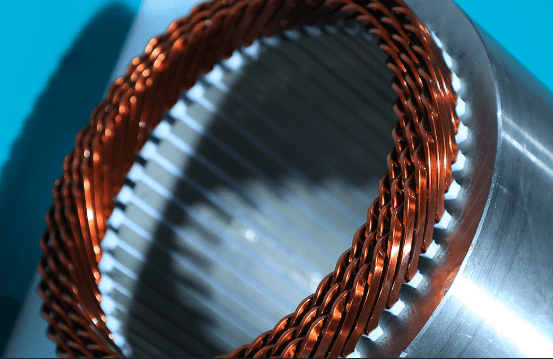

Insertion Technology

Challenges in the Inner Diameter Insertion Process

The inner diameter insertion method requires applying uniform expansion pressure between the expander and the copper wire, pushing the winding evenly into the stator slots without damaging the insulation paper. The dimensional accuracy and surface smoothness of the expander are critical; any deviations or surface roughness can scratch the insulation, compromising its integrity and potentially causing electrical shorts. Additionally, the deformation of the copper wire under pressure must be carefully controlled to maintain coil shape stability, ensuring proper assembly and optimal electrical performance.

Challenges in the Outer Diameter Insertion Process

In the outer diameter insertion process, the winding is first placed around the stator teeth, followed by fitting an iron core sleeve externally and welding it in place. While this method simplifies some aspects of insertion, it poses mechanical strength challenges since welding is limited to the iron core surface. This can lead to localized stress concentrations. The quality and precision of welding directly affect the structural integrity of the stator core and the firmness of the winding fixation, which in turn influence motor reliability and durability. Therefore, optimizing welding techniques and maintaining strict quality control are essential to ensure overall motor performance.

Insulation Technology

Selection of Insulation Materials

Due to the unique structure and high slot fill factor of W-pin windings, insulation materials must meet stringent performance criteria. They require excellent electrical insulating properties to prevent current leakage and short circuits, along with high thermal resistance to withstand the heat generated during prolonged high-load motor operation. Additionally, robust mechanical strength and chemical stability are essential to ensure the insulation layer remains intact despite vibrations, mechanical shocks, or chemical exposure, thereby ensuring the overall safety and reliability of the motor.

Implementation of Insulation Processes

During winding, forming and insertion processes, maintaining the integrity and uniformity of insulation materials is critical. Any damage or peeling of the insulation varnish during continuous winding forming can severely compromise electrical performance and durability. During insertion, the insulation paper must remain securely positioned and undamaged to prevent short circuits or leakage faults caused by insulation displacement or breakage. Furthermore, insulation processes must be compatible with high-speed automated production, ensuring each stage meets strict quality control standards.

Welding Technology

Welding Accuracy and Strength

The quality of end welding in W-pin windings is critical to the motor’s electrical performance and reliability. Any deviation in welding position can cause unstable electrical connections, resulting in increased resistance, overheating, or even motor failure. Additionally, the welds must possess sufficient strength to withstand high-speed rotation and vibrations during motor operation, ensuring the weld joints do not detach or fracture over time and maintaining long-term stable performance.

Welding Fixture Design

Given the complex shape and compact structure of W-pin windings, the design of welding fixtures is a crucial factor. Fixtures must securely hold the windings in place to prevent displacement during welding, while also facilitating easy operation and compatibility with various welding methods such as laser welding or resistance welding. Efficient and precise fixture design not only improves weld quality but also significantly enhances production efficiency and automation capabilities.

Equipment Precision and Stability

High Precision Requirements for Equipment

Critical equipment involved in the W-pin winding process, such as winding machines, insertion machines, and welding machines, must meet stringent precision standards. For instance, winding machines need to ensure accurate wire placement to prevent coil overlap or uneven gaps; insertion machines require precise positioning to smoothly insert windings into stator slots; welding machines must guarantee exact weld locations and parameters to avoid defects. Any lack of precision in these steps can degrade coil formation quality and ultimately impact motor performance.

Ensuring Equipment Stability

During continuous high-volume production, stable equipment operation is essential for maintaining production efficiency and product quality. Equipment failures or performance fluctuations can cause production stoppages and increase defect rates, leading to wasted resources and financial losses. Therefore, implementing a comprehensive maintenance and servicing program, including regular calibration and inspections, is critical to detect and address potential issues early. This ensures equipment remains in optimal condition, enabling efficient and stable manufacturing processes.

W-Pin motor production using automation equipment still presents significant challenges across the industry. While this technology continues to evolve, HONEST Automation currently supports customers with reliable solutions for Hairpin motors, X Pin motors, and Mini Pin motors.

We offer prototyping, small-batch production equipment, as well as fully and semi-automated assembly lines tailored to your specific motor manufacturing needs.

You're welcome to leave us a message or contact us by email—we'll get back to you as soon as possible with expert support and customized solutions to help you improve production efficiency and quality.