In the world of electric motor manufacturing, choosing the right armature coil winding machine is a critical decision. Whether you are producing motors for power tools, household appliances, or automotive applications, the quality and efficiency of your armature winding process directly impact product performance, production speed, and manufacturing costs.

This guide will help you understand what to consider when selecting an armature winding machine that fits your specific needs.

1. Understand Your Application Requirements

Before choosing any machine, it’s essential to clearly define your product and production goals:

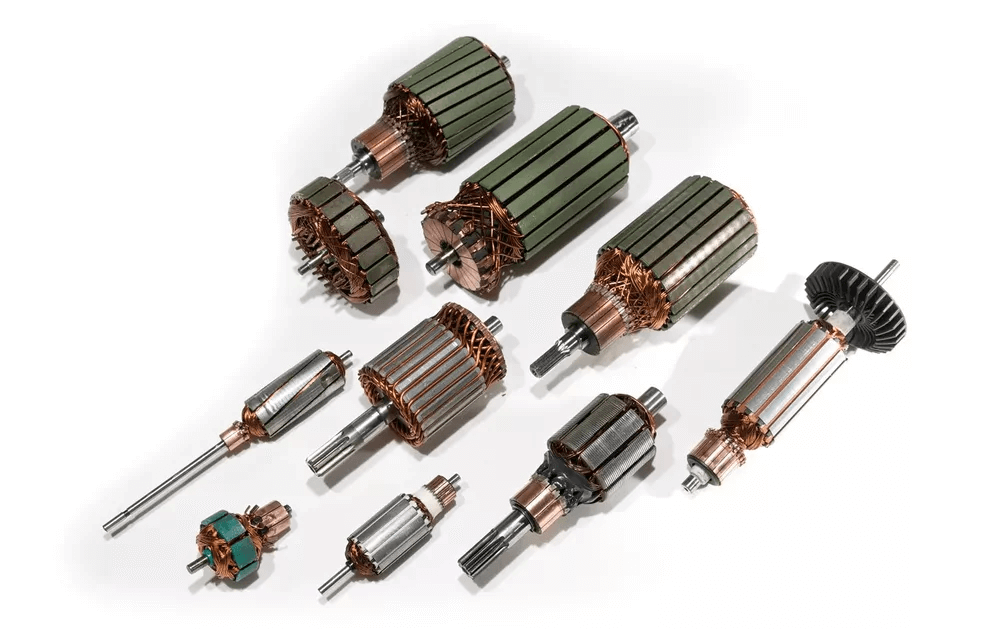

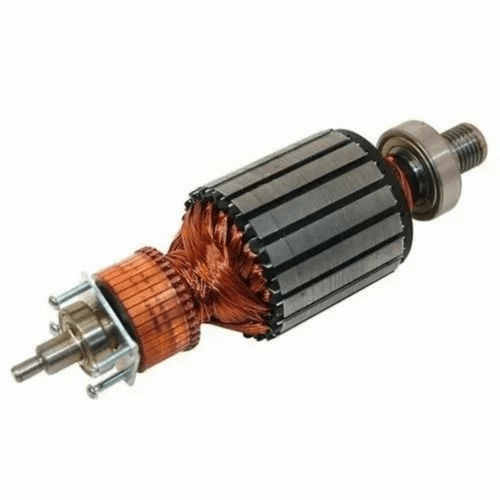

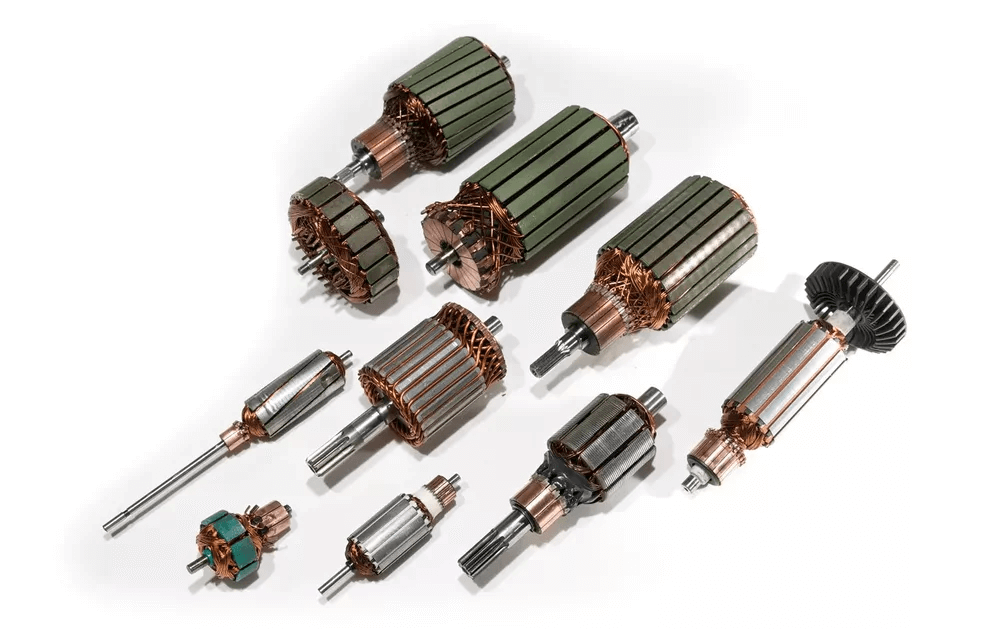

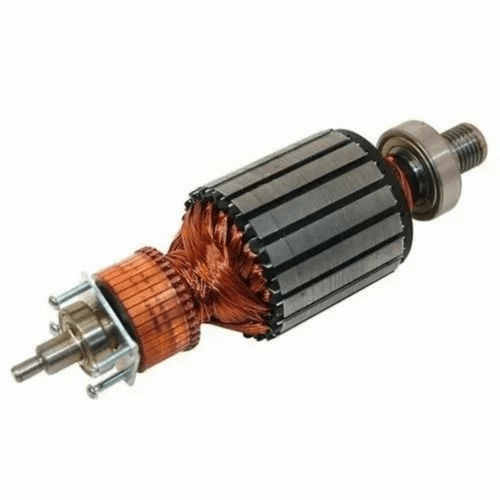

Armature specifications: What is the size, number of slots, and wire gauge?

Motor type: Automotive motors (e.g., starter, wiper), power tool motors (e.g., grinders, drills), or household appliance motors (e.g., vacuum cleaners)?

Production volume: Are you looking to produce in small batches or at high volume?

Winding pattern: Do you require lap winding, wave winding, or a specific slot-fill method?

Understanding these details will ensure you select a machine that matches your technical and production needs.

2. Types of Armature Winding Machines

There are several types of machines available, depending on your automation goals:

Manual Armature Winding Machine

Ideal for low-volume production or repair applications. These machines require significant operator involvement and are generally not suitable for mass production.

Semi-Automatic Armature Winding Machine

These machines offer a balance between automation and affordability. Operators assist with wire feeding or switching, but the machine handles winding and tension control. Suitable for medium production volumes.

Fully Automatic Armature Winding Machine

Designed for high-speed, high-volume manufacturing. These systems automate wire feeding, slot indexing, commutator hooking, and wedge insertion. Ideal for automotive and industrial motor manufacturers who demand consistent quality and efficiency.

3. Key Features to Look For

When comparing machines, prioritize features that directly impact performance and usability:

Winding speed and precision: Fast winding with consistent slot filling ensures product reliability.

Tension control: Accurate wire tension avoids coil damage and improves uniformity.

PLC or HMI system: Touch-screen control panels allow easy parameter settings, recipe storage, and fault diagnosis.

Automatic commutator hooking and wedging: Reduces manual labor and improves repeatability.

Additional features like wire break detection, auto wire cutting, and remote diagnostics can further streamline your process.

4. Consider the Machine Price vs. Value

Price is always a factor, but it should be evaluated against long-term value:

Keep in mind that higher initial investment in automation often results in lower labor costs, improved product consistency, and faster ROI. HONEST Automation offers flexible solutions tailored to your budget and capacity requirements.

5. After-Sales Support Matters

Even the best machine needs reliable service and support:

Does the supplier offer overseas installation and training?

Is technical support available in your region or time zone?

How quickly can they deliver spare parts?

Do they offer online diagnostics or software upgrades?

At HONEST Automation, we provide full-service global support—from installation and commissioning to remote troubleshooting and preventive maintenance.

6. Real-World Application: Automotive Armature Production

One of our clients, a leading Tier-1 automotive supplier, upgraded from manual winding to a fully automated armature winding line supplied by HONEST Automation. The result:

Production efficiency increased

Labor cost reduced

Consistent quality across all batches

Our solution included dual-station automatic winding, integrated hooking and wedge insertion, and automated unloading—all customized for their specific armature design.

Make the Right Choice with Confidence

Choosing the right armature coil winding machine requires balancing technical needs, production goals, and budget. By understanding your product, comparing machine types, and selecting a supplier with strong support, you can significantly improve your manufacturing efficiency.

Ready to automate your armature winding process?

Contact HONEST Automation Today

Let our experts help you find the perfect winding solution for your motor production line.