The technical challenges of the W-pin winding process primarily lie in the following aspects:

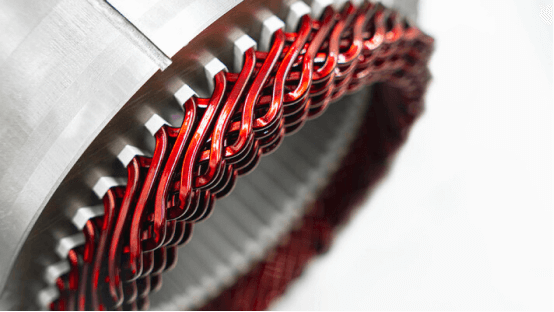

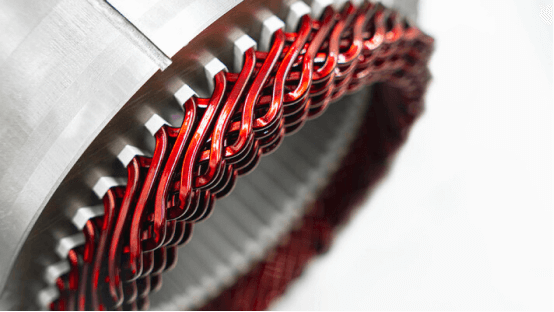

Winding and Forming Technology

High Precision Requirement for Wire Dimensions

W-pin windings typically use flat wire, which demands extremely high precision in wire dimensions. If the wire is too thick or too thin, it can compromise the quality and performance of the formed windings. This may lead to difficulties in subsequent insertion processes, as well as poor fit between the windings and the stator core.

Stability in Continuous Forming

During the continuous forming process, it is crucial to maintain stable parameters such as wire tension, bending angles, and twisting positions. Even the slightest deviation can result in irregular winding shapes, ultimately affecting the motor’s performance and assembly accuracy.

Insertion Technology

Challenges of Inner Diameter Insertion

When using the inner diameter insertion method, the winding must be uniformly expanded into the stator slots through the pressure applied between the expansion blades and the copper wire without damaging the insulation paper. This requires extremely high dimensional precision and surface smoothness of the expansion blades. Otherwise, the insulation paper can be scratched, or the copper wire may deform, compromising the winding's integrity.

Challenges of Outer Diameter Insertion

In the outer diameter insertion process, the winding is first formed around the stator teeth, then an outer core sleeve is placed over it and welded. However, this method only allows welding on the outer surface of the core, which presents structural challenges in terms of core strength. Furthermore, the welding quality and accuracy directly affect the stator core's overall performance and the winding fixation's stability.

Insulation Technology

Selection of Insulation Materials

Due to the unique structure of W-pin windings and their relatively high slot fill factor, the performance requirements for insulation materials are significantly more stringent. Materials must possess excellent electrical insulation, high thermal resistance, mechanical strength, and chemical stability to ensure the long-term safety and reliability of the motor during operation.

Implementation of Insulation Processes

Throughout the winding forming and insertion processes, it is essential to maintain the integrity and uniformity of insulation materials. For example, during continuous winding formation, damage to the insulation enamel must be avoided. During the insertion process, displacement or damage to the insulation paper must be prevented, as these issues could result in inter-turn short circuits or insulation leakage, ultimately compromising motor performance.

Welding Technology

Welding Precision and Strength

End welding of W-pin windings demands high precision and strength. Any deviation in welding position may lead to poor electrical connections, adversely affecting motor performance. Insufficient welding strength can result in joint failure or detachment during motor operation.

Welding Fixture Design

Due to the structural characteristics of W-pin windings, the design of welding fixtures is relatively complex. It is essential to ensure the windings are securely and accurately positioned during welding while maintaining ease of operation and consistent welding quality.

Equipment Precision and Stability

High Precision Requirements

The W-pin winding process involves equipment such as winding machines, inserting machines, and welding machines, all of which must deliver high precision. For example, the winding machine’s wire-laying accuracy, the inserting machine’s positioning accuracy, and the welding machine’s joint precision all have a direct impact on the quality and efficiency of the winding process.

Ensuring Equipment Stability

During continuous production, equipment must maintain a stable operating condition. Any malfunction or performance degradation can interrupt production or compromise product quality. Therefore, regular maintenance and servicing are essential to ensure long-term equipment reliability and stability.

W-pin Motor Process Flow:

Slot bottom insulation paper insertion → Winding wire forming → Wire laying → Coil winding → Wire insertion → Slot cover insertion → Three-phase wire welding → Varnish dipping → Testing

Challenges in the W-pin Winding Process:

Uneven stress on the copper wire, leading to a high risk of damage

Coil easily sags or bends during forming and transfer

Unstable coil shape and dimensions after forming

High difficulty in achieving full automation

Risk of enamel coating damage during precise wire laying

The slot cover may protrude into the stator's inner diameter, causing poor insulation

Advantages and Disadvantages of W-pin Windings

Disadvantages:

In the event of insulation failure or other issues, the entire wire may need to be replaced, making repair far more difficult than for hairpin windings, especially with multilayer braided structures, where rework is nearly impossible.

The process requires repeated bending and threading from both directions. To ensure smooth insertion into each slot, the straightness and insertion angle of the wire after bending must be tightly controlled.

Due to wire spring-back, the position of internal wires is hard to control, and maintaining consistency in the end braiding structure is a challenge.

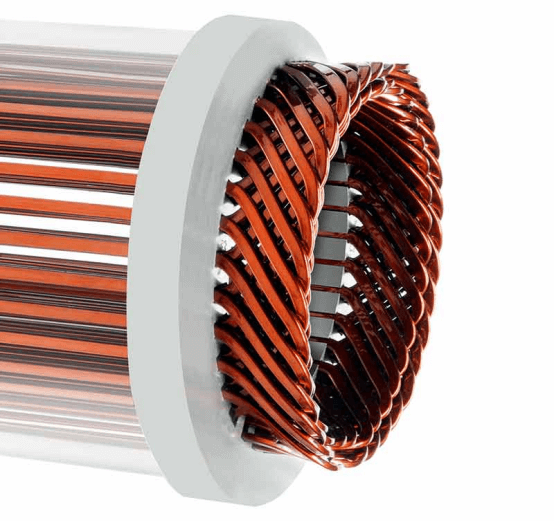

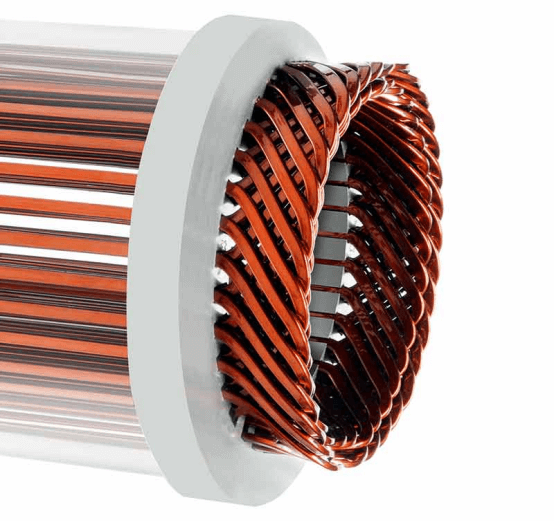

Advantages:

There are no welds or copper busbar connections like in hairpin windings. Only local welding is required at points such as the neutral point, output line, and parallel connections—this significantly reduces the number of process steps and saves manufacturing cost.

W-pin windings do not require end welding, and the wire length is much shorter than hairpin types.

NVH (Noise, Vibration, Harshness) performance is superior, reducing torque ripple and enabling smoother motor operation.

W-pin vs Hair-pin Windings

No Welds at Both Ends

W-pin wave windings feature no welds at either end, eliminating the need for straight segments required for welding. In addition, the coating process is not needed. As a result, for the same wire diameter and span, the end height of a W-pin product is significantly lower than that of a Hair-pin design.

No Flaring or End Welding Required

For a 10-layer W-pin wave winding, the end diameter is approximately 20 mm shorter than that of a Hair-pin. This is because Hair-pin designs require at least a 2 mm spacing between weld points for insulation purposes, which increases overall winding dimensions.

No Cutting Head or Wire Trimming Processes

W-pin windings have a higher copper wire utilization rate. Hairpin windings involve wire trimming, which leads to a certain amount of material waste.

No Welding Needed

W-pin windings carry a lower quality risk. In contrast, Hair-pin windings have many welding points, making quality control more difficult and reducing the yield rate.

No Need for Stripping, Cutting, or Welding

W-pin windings offer better cleanliness control, making them more suitable for oil-cooled motors. Hairpin windings, due to the multiple processing steps involved, are more challenging in terms of cleanliness management.

HONEST Automation provides complete motor assembly solutions—including prototyping, small-batch production, and fully automated production lines—for Hairpin motors, X Pin motors, and Mini Pin motors. You're welcome to leave us a message or contact us by email; our technical experts will respond as soon as possible to assist you with tailored solutions.

Tel: +8618923732990

E-mail: sales@honest-hls.com