What is the starter motor structure?

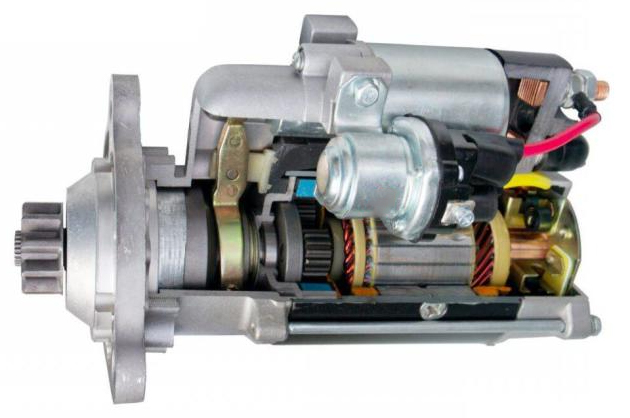

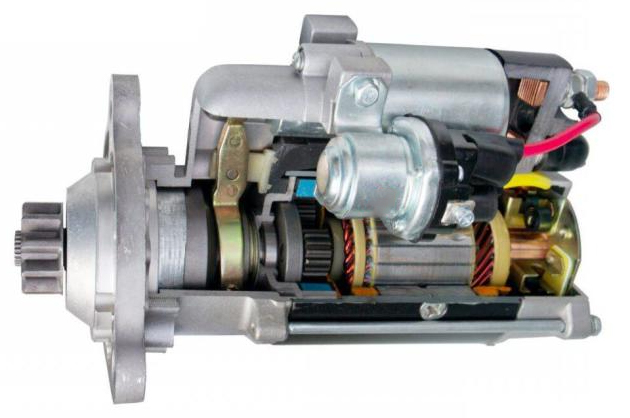

Armature Rotor: The armature rotor is the rotating part of the DC motor. It is an iron core made of stacked silicon steel sheets with slots. Thick wire winding is wound in the slots to withstand large starting currents (200-600A).

Magnetic Pole Stator: The magnetic pole stator consists of an iron core and a magnetic pole winding fixed on the casing. It usually contains two pairs of magnetic poles, which together with the casing form a magnetic circuit.

Commutator: The function of the commutator is to introduce current into the rotating armature. It is composed of multiple dovetail-shaped copper sheets and mica sheets superimposed, and the armature winding is welded at the dovetail.

Brush and Brush Holder: The brush is made of copper powder and carbon powder. The positive brush holder is insulated and connected to the end cover. The negative brush holder is directly connected to the end cover and is responsible for transmitting electric energy to the commutator.

Electromagnetic Switch: It controls the on and off of the starter circuit and is an important part of the starting system.

Transmission Mechanism: The transmission mechanism, also called the starter clutch or meshes, is responsible for meshing the starter pinion into the flywheel ring gear when the engine is started, transmitting torque, and automatically disengaging after the engine is started to protect the starter motor from avoiding damage.

One-way Clutch: It ensures that when the starter drives the crankshaft to rotate, the one-way clutch allows power transmission; when the engine is started, because the speed is higher than the starter motor, the clutch is disengaged to avoid reverse drive damage to the starter.

Gear Reduction Mechanism: Installing a gear reducer between the motor’s armature shaft and the driving gear can reduce the motor’s speed while increasing its torque.

Planetary Gear Reduction: Some starters contain a planetary gear reducer, which is connected to the armature shaft to increase the torque output during starting.

What is the classification of starter motors?

Starter motors are classified in many ways according to different standards, the details are as follows:

1. Classification by power supply type

DC Motor: A motor powered by a DC power supply, including ordinary DC motors, DC geared motors, brushed and brushless types.

AC Motor: A motor powered by AC power, which is further divided into asynchronous motor, synchronous motor, and switched reluctance motor.

2. Classification according to structure and working principle

Stepper Motor: An open-loop control motor that converts electrical pulse signals into angular displacement or linear displacement. It is divided into reactive, permanent magnet, and hybrid types.

Servo Motor: A motor that can precisely control position, speed, and acceleration, with high dynamic response performance and accuracy.

Torque Motor: It outputs constant torque and can run continuously in locked-rotor mode without causing damage to the motor.

3. Classification by startup and operation methods

Full Voltage Direct Starting: The motor is started by applying rated voltage to the motor winding.

Autocoupling Decompression Start: It uses an autotransformer for decompression start, suitable for large-capacity motors.

Y-Δ Start: When starting, connect the stator winding into a star shape, and then connect into a delta shape after starting. It is suitable for no-load or light-load starting.

Soft Starter: It utilizes the phase-shifting and voltage and voltage-regulating principle of the thyristor to realize the voltage-regulated starting of the motor. The starting effect is good but the cost is high.

Frequency Converter Starting: By changing the frequency of the power grid to adjust the speed and torque of the motor, it is suitable for areas that require speed regulation and high-speed control.

4. Classification by exercise method

Stationary Motor: such as a transformer.

Rotating Motors: such as DC motors, and AC motors.

Linear Motor: such as linear synchronous motor, linear asynchronous motor, and so on.

5. Classification by use

Stepper Motor: It is used in CNC machine tools, robots, and other fields. It has the advantages of high positioning accuracy, smooth operation, and low noise.

Servo Motor: It is used in automatic control systems, robots, and other fields, with high dynamic response performance and accuracy.

Torque Motor: It is used in hoisting equipment, elevators, and other fields. It has the advantages of large starting torque and good speed regulation performance.

How does a starter motor work?

A starter motor is an electric motor designed to provide high torque for a short period to start an internal combustion engine. Its working principle is based on electromagnetism. The electric current generates a rotating magnetic field in the stator coil, which attracts and repels the electromagnet on the rotor, causing the rotor to rotate. The rotation of the rotor is transmitted to the flywheel of the engine through the meshing gear, overcoming the static friction of the engine, and thereby starting the engine. Once the engine is started, the starter motor’s automatic disengagement mechanism disengages the meshed gear, preventing the motor from overloading. Starter motors are usually equipped with overload protection devices and require regular maintenance to ensure their performance and longevity.

The following will introduce in detail the working principles of two common starter motors:

Direct-On-Line (DOL) Starter: It is the simplest and most common starting method. In direct starting, the motor is started by applying rated voltage to the motor winding. During the starting process, the motor will generate enough starting torque to overcome the static friction and load torque and gradually accelerate to the rated operating speed. Direct starting is suitable for small power motors and applications with light loads.

Y-Δ Starter: For high-power motors or applications requiring large starting torque, the star-delta starting method is often used. In star starting, the starting process of the motor is divided into two stages: star connection and delta connection. When starting, the motor is first started in star connection, that is, the motor winding is divided into three parallel parts, and each part is connected to the power supply. This reduces current and torque. When the motor reaches sufficient speed, it switches to the delta connection mode to continue running. This provides higher torque and lower current.

Application of starter motor in automobiles

The starter motor is used in automobiles as the core component of the starting system, and its main function is to start the internal combustion engine. The following are the specific applications and functions of starter motors in automobiles:

Starting the Internal Combustion Engine: When the driver operates the ignition switch or the start button, the starter motor receives current from the battery, generates sufficient torque, and meshes with the flywheel ring gear of the engine through the meshing gear to drive the engine crankshaft to rotate, thereby starting the internal combustion engine.

Circuit Control: The work of the starter motor is usually controlled by an electromagnetic switch, which is controlled by the ignition switch or the start button and is responsible for connecting or disconnecting the current to make the starter motor work or stop.

Automatic Disengagement: After the engine is started, the meshing gear of the starter motor will automatically disengage from the flywheel ring gear to prevent the starter motor from being damaged due to the high engine speed.

Short-time Working Design: The starter motor is designed to work for a short time, only used for a few seconds when starting the engine, and then stops working.

Cooperation with the Battery and Generator: The starter motor works in conjunction with the car's battery and generator. The battery provides the electrical energy needed to start, while the alternator powers the vehicle's electrical system and charges the battery while the engine is running.

Maintain the Engine: The starter motor ensures that the engine can start reliably and avoids additional wear on the engine caused by frequent starts.

Integration in Modern Vehicles: In modern vehicles, the starter motor may be combined with the generator into a single component, called a combined starter generator, which can function as both a starter motor and a generator when the engine is running.

Mild Hybrid System: In some mild hybrid vehicles, the starter motor also has the function of assisting the engine to provide additional power to help the vehicle assist when accelerating or climbing hills.

About HONEST HLS

HONEST HLS has engaged in providing intelligent equipment solutions for electric motors for 17 years. We can offer you product proofing if you offer us the product design drawings. And if you want to know more information about HONEST HLS, please feel free to contact us, we will be glad to send you our company introduction presentation.