The drive motor of a car is one of the core components of electric and hybrid vehicles, responsible for converting electrical energy into mechanical energy to propel the car forward, which is usually located between the gearbox and differential.

There are many types of drive motors, and the common ones are as follows:

A. DC Motor: this is a commonly used type in early electric vehicles and is divided into brushed DC motors have the characteristics of simplicity, low cost, but complex maintenance, and short lifespan; brushless motors have the characteristics of high cost but high efficiency, long lifespan and low maintenance requirements;

B. AC Motor

1. AC Induction Motor: this type of motor has no permanent magnets and relies on the magnetic field generated by current to drive the rotor. It has the advantages of a simple structure, low maintenance cost, and high-temperature resistance.

2. AC Asynchronous Motor: this type usually refers to the permanent magnet synchronous motor, which uses permanent magnets to generate a magnetic field. It has high efficiency and small size. It is one of the most commonly used motor types in electric vehicles. The structure of the permanent magnet synchronous motor includes the stator, rotor, motor shaft, front and rear bearings, end cover, cooling water channel, position sensor, temperature sensor, and low-voltage wiring harness. The stator consists of a stator core and three-phase winding; the rotor consists of permanent magnet poles and an iron core, which is made of silicon steel sheets.

The arrangement of permanent magnets in the rotor, mainly includes surface-protruding permanent magnet rotors, surface-embedded permanent magnet rotors, and built-in permanent magnet rotors.

The working principle of the drive motor:

1. DC Motor: it works based on Faraday’s law of electromagnetic induction, which states that when a closed conductor is moved in a magnetic field, an electromotive force is generated in the conductor, which produces an electric current.

A DC motor consists mainly of a stator, rotor, commutator, and brushes.

2. AC Asynchronous Motor: to drive and provide torque, an AC asynchronous motor needs to pass three-phase alternating current into the stator coil to generate a continuously rotating magnetic field.

3. AC synchronous motor: the stator provides a rotating magnetic field. The method and speed of magnetic field generation are the same as those of an AC asynchronous motor. The magnetic poles are provided by the rotor's permanent magnets. In this way, the rotating magnetic field generated by the stator forms a loop with the rotor's permanent magnet poles and the rotor core.

According to the principle of minimum reluctance, that is, the magnetic flux is always closed along the path of minimum reluctance, and the electromagnetic force of the rotating magnetic field is used to pull the rotor to rotate. Then the permanent magnet rotor will rotate synchronously with the rotating magnetic field generated by the stator, thereby driving the motor shaft to rotate.

The common denominator of the above operating principles of drive motors: both DC and AC motors are based on the Lorentz force, when a current passes through a conductor placed in a magnetic field, the conductor is subjected to a force perpendicular to the direction of the current and the direction of the magnetic field. Using sophisticated design, motors can efficiently convert electrical energy into mechanical energy, which is used to drive a wide range of equipment and carries.

There are several factors to consider when selecting a drive motor:

1. Power and torque requirements: determine the size and type of motor;

2. Efficiency: affects cruising range and energy consumption;

3. Cost: including purchase cost, maintenance cost, and service life;

4. Weight and volume: Especially in electric vehicles, they have a direct impact on the performance of the vehicle;

5. Usage environment: such as temperature, humidity, etc. Different motors have different tolerances;

6. Control complexity: Different types of motors require different control strategies and hardware.

development trend

As the fields of electric vehicles and renewable energy grow, so does the technology that drives electric motors. Current research and development trends include:

Improve efficiency: reduce energy loss through material innovation and design optimization;

Reduce costs: find ways to replace rare earth materials and simplify production processes;

Lightweight and miniaturized: improve energy density and reduce space occupation;

Intelligent control: Utilize advanced electronic control strategies and software to improve motor performance and adaptability.

The drive motor is one of the key technologies for electrification, and it plays a vital role whether in the fields of transportation, industrial production, or household appliances. With the continuous development of technology and further reduction of costs, the application range of drive motors will become wider.

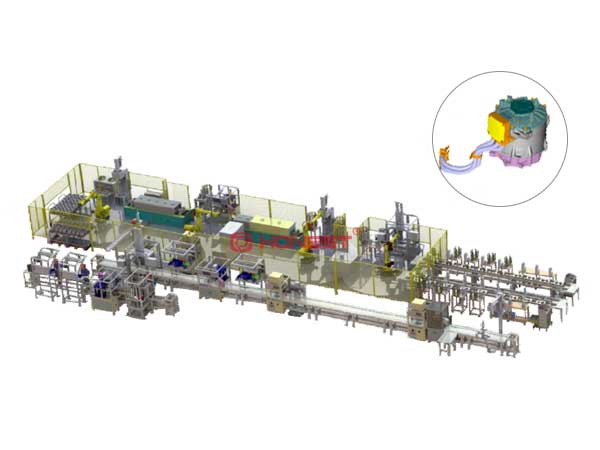

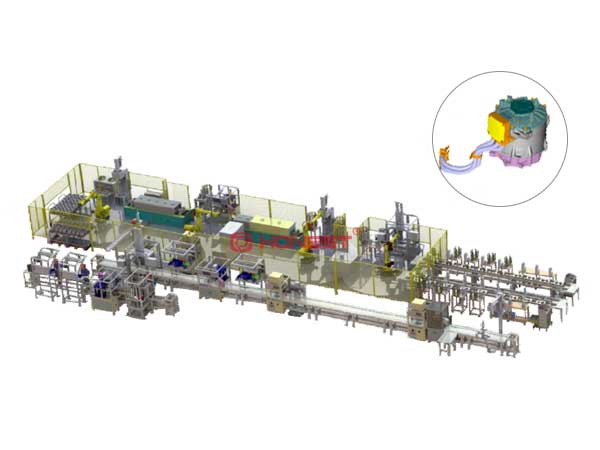

If you need drive motor assembly line or rotor assembly line, please leave a message online to get a customized solution and quotation.