The electric air conditioning outlet adjustment motor is a sophisticated actuator that plays a crucial role in automotive air conditioning systems. Its primary function is to adjust the direction and volume of the airflow from the outlet precisely by receiving commands from the vehicle’s control system. Typically installed within the outlet, it is connected to the air conditioning control panel via a wire. When the user adjusts the air settings, the control panel sends signals to the motor, instructing it to move the outlet to the desired position.

There are generally two types of electric air conditioning outlet adjustment motors: stepper motors, known for their precise angular control, and DC motors, favored for their smooth speed control and cost-effectiveness.

Working Principle

User Interface Input: The user selects the desired airflow mode, such as direction and speed, through the air conditioning control panel.

Signal Conversion: The air conditioning microcontroller receives the user’s input and converts it into motor control signals.

Motor Control

1.Stepper Motor: It controls the motor’s rotation by receiving pulse signals. Each pulse rotates the motor by a fixed angle (step angle), achieving precise angular control.

2.DC Motor: It controls the motor’s speed by adjusting the voltage across the motor’s terminals. The direction of rotation is determined by the polarity of the voltage.

Motor Drive Circuit: The motor drive circuit receives signals from the controller and converts them into current and voltage suitable for the motor.

Mechanical Transmission System: The motor’s rotation is transmitted to the outlet adjustment mechanism through mechanical structures such as reduction gears, worm gears, and connecting rods.

Position Feedback System: For stepper motors, position feedback is usually not required due to their open-loop control characteristics, but it can be added to improve control accuracy. For DC motors, a position sensor (such as an optical encoder) provides real-time feedback to ensure the motor rotates to the correct position.

Closed-Loop Control System: The feedback signal from the position sensor is sent back to the microcontroller, forming a closed-loop control to ensure the accuracy of the outlet adjustment.

Safety Features: The motor control system is designed with current detection and temperature detection to prevent overload and overheating, protecting the motor and user safety.

Energy Consumption Optimization: The motor and control system is designed with energy efficiency in mind, reducing energy consumption through optimized motor parameters and control algorithms.

Diagnostics and Maintenance: Modern motor control systems often have self-diagnostic capabilities, monitoring the status of the motor and control system, and alerting for maintenance when necessary.

Technical Specifications

Torque: The force that the motor can provide, determining the moving capability of the outlet adjustment mechanism.

Speed: The rotational speed of the motor, affects the response time of the outlet adjustment.

Efficiency: The efficiency with which the motor converts electrical energy into mechanical energy, affecting energy consumption.

Lifespan: The expected service life of the motor, which is usually related to materials, manufacturing processes, and operating conditions.

Advantages

Rapid Response: The motor can quickly respond to control signals, achieving fast outlet adjustment to adapt to temperature changes or user demands.

Low Noise Operation: Designed with an emphasis on noise reduction, the motor operates almost silently, providing a more comfortable driving environment.

High Reliability and Durability: The motor and control system are designed for long-term reliability, using high-quality materials and sealing techniques to reduce failure rates and extend service life.

Energy-Efficient: The motor design optimizes energy efficiency, reducing energy consumption and helping to lower the overall operating costs of the air conditioning system.

Intelligent Integration: The motor control system can be integrated with smart home systems or other smart devices for remote control and automated adjustment.

Safety Protection Measures: The motor control system has overload, overheating, and short-circuit protection functions to ensure safety during use.

User-Friendly Interface: The motor control system usually comes with an intuitive user interface, making it easy for users to set and adjust the outlet.

Modular Design: The motor and control system are designed modular for easy upgrades and part replacement, adapting to technological advancements and changing user needs.

Custom Programming: Some advanced motor control systems support programming to meet specific application requirements.

Low Maintenance Costs: Due to the high-quality design of the motor and control system, their maintenance needs are low, reducing long-term operating costs.

The advantages of the electric air conditioning outlet adjustment motor make it an indispensable technical component of modern air conditioning systems, providing not only user comfort and satisfaction but also contributing to energy efficiency and environmental sustainability goals.

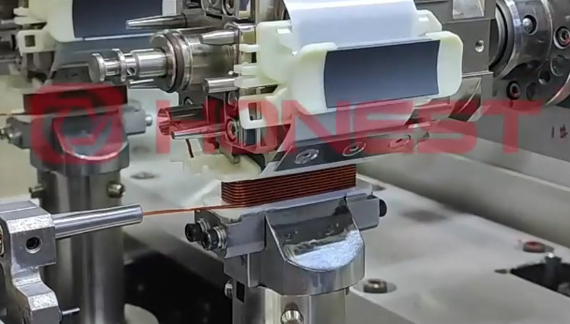

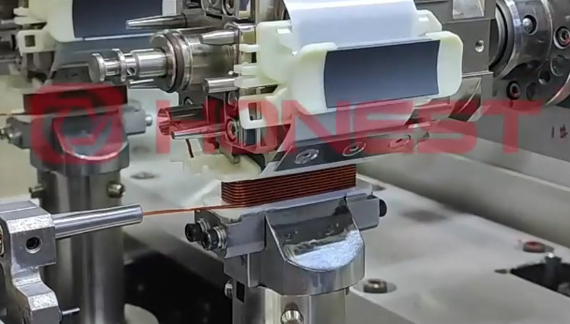

Assembly Process Characteristics

The electric air conditioning outlet adjustment motor is one of the significant applications in the field of intelligent motor equipment. Its assembly process involves the selection, assembly, and debugging of motor components and has the following characteristics.

High Precision Requirement

The electric air conditioning outlet adjustment motor is responsible for controlling the direction and angle of the air conditioning outlet, and its working precision directly affects the cooling and heating effects of the air conditioning system as well as user comfort. Therefore, the selection and assembly of motor components must meet high precision standards.

High-Efficiency Requirement

When operating within the air conditioning system, the electric air conditioning outlet adjustment motor needs to provide sufficient torque within a small volume to meet the adjustment requirements of the outlet. Hence, the motor must have high efficiency to reduce power consumption and heat generation.

High-Reliability Requirement

The electric air conditioning outlet adjustment motor needs to operate continuously for extended periods, and the working environment can be harsh. Therefore, the motor must have high reliability to ensure long-term stable operation.

High Degree of Automation

With the continuous development of intelligent manufacturing technology, the assembly process of the electric air conditioning outlet adjustment motor is becoming increasingly automated. Automated production lines can improve production efficiency and product quality while reducing production costs.

Flexible Production

With the diversification of market demands, the specifications and models of the electric air conditioning outlet adjustment motor are also increasing. Therefore, the motor production line needs to have a certain level of flexible production capabilities to quickly adapt to changes in market demand.

Control Methods

Open-Loop Control

Open-loop control is the simplest form of control, where the control system does not feedback on the actual output state of the controlled object but directly controls the actuator based on the set value. Open-loop control is characterized by its simple structure and ease of implementation, but it has low control precision and is susceptible to interference.

In the electric air conditioning outlet adjustment motor, open-loop control is usually used to control the motor’s speed. For example, when a user adjusts the air volume through the air conditioning control panel, the control system sends corresponding control signals to the motor based on the set air volume value, and the motor rotates according to the instructions, thereby changing the air volume.

Closed-Loop Control

It refers to a control system that feeds back the actual output state of the controlled object and adjusts the controller’s output based on the feedback information to make the output value of the controlled object close to the set value. Closed-loop control improves control precision and resists interference by adjusting the controller’s output based on the actual output state feedback.

In the electric air conditioning outlet adjustment motor, closed-loop control is usually used to control the motor’s angle. For example, when a user adjusts the direction of the air outlet through the air conditioning control panel, the control system detects the actual angle of the air outlet and compares it with the set target angle. If there is a deviation, the control system sends corresponding control signals to the motor, and the motor rotates according to the instructions until the air outlet reaches the target angle.

Fuzzy Control

It is a control method based on fuzzy logic. Fuzzy control uses fuzzy logic to handle uncertainty and nonlinear issues, suitable for control scenarios where it is difficult to establish an accurate model.

In the electric air conditioning outlet adjustment motor, fuzzy control can be used to control the motor’s speed and angle. For example, in some air conditioning systems, users can adjust the direction or air volume of the air outlet through voice commands. Since voice commands often have ambiguity, fuzzy control can be used to control the motor.

Neural Network Control

Neural network control is a control method based on artificial neural networks, simulating the neural network of the human brain to achieve self-learning and self-adaptation and optimize control strategies.

In the electric air conditioning outlet adjustment motor, neural network control can be used to optimize the motor’s control strategy. For example, a neural network can be trained to learn the nonlinear characteristics of the motor, and the parameters of the controller can be adjusted according to the learning results, thereby improving control precision.

Intelligent Control

It refers to the comprehensive application of various control methods, combined with artificial intelligence technology, to achieve intelligent control of the controlled object. Intelligent control has strong self-learning, self-adaptation, and decision-making capabilities, effectively solving complex control problems.

In the electric air conditioning outlet adjustment motor, intelligent control can be used to achieve more precise and comfortable control effects. For example, fuzzy control, neural network control, and other control methods can be combined with expert systems, knowledge bases, and other technologies to build an intelligent control system, achieving adaptive control of the motor, and providing more comfortable air outlet effects according to the user’s personalized needs.

The control method for the electric air conditioning outlet adjustment motor should be selected according to specific application scenarios and requirements.

HONEST HLS is a manufacturer with rich experience in manufacturing motor production equipment. For over a decade, we have been committed to research and innovation, determined to design equipment and production lines that reduce production costs and improve efficiency. For inquiries about our motor production equipment or to discuss customized solutions, please feel free to contact us.