In recent years, the continuous surge in new energy vehicle (NEV) sales has brought increasing attention to the braking system, one of the most critical components for vehicle safety. The EMB (Electromechanical Brake) motor is a precision-engineered unit specifically designed for NEV braking systems. It features a compact structure and integrates key components such as the motor body, a high-precision control unit, and highly responsive sensors. Within NEV braking architecture, the EMB motor significantly enhances braking performance and response speed, offering an innovative solution to improve overall driving experience.

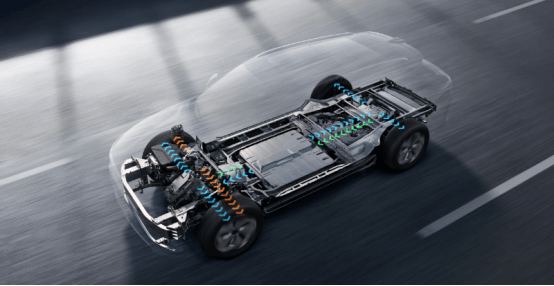

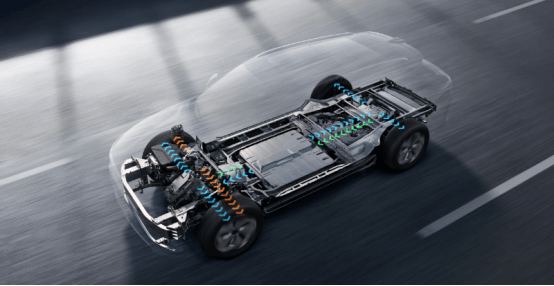

When the vehicle needs to decelerate or come to a stop, the EMB motor is activated instantly. The control unit rapidly processes real-time data such as the vehicle's operating status and the driver's brake pedal input, both in terms of force and speed. Based on these signals, it issues precise commands to the motor. The motor then accurately converts electrical energy into mechanical energy, driving the brake disc or drum to generate powerful braking force, ensuring the vehicle slows down smoothly and comes to a complete stop.

This braking process is not only fast and precise but also minimizes the energy losses typically found in conventional braking systems. It enables efficient recovery and reuse of braking energy, aligning perfectly with the core values of new energy vehicles—high efficiency and environmental sustainability. As a result, the overall performance and energy economy of the vehicle are significantly enhanced.

Key Advantages and Application Scenarios of EMB Motors

1. Enhanced Braking Performance

EMB motors significantly improve a vehicle’s braking capability. With their precision control features, the braking force can be intelligently adjusted in real time based on road conditions, vehicle speed, and the driver’s input. This ensures smoother, more efficient, and safer braking performance.

2. Improved IBC System Efficiency

EMB motors work seamlessly with Integrated Brake Control (IBC) systems to precisely manage regenerative braking force. During deceleration or braking, the system maximizes the conversion of kinetic energy into electrical energy, which is then efficiently fed back into the vehicle’s battery pack. This enhances overall energy utilization and supports the vehicle’s energy-saving goals.

3. Aligned with the Demands of New Energy Vehicles

EMB motors eliminate the need for complex hydraulic lines found in traditional braking systems by adopting a fully electronic, highly integrated control design. This not only simplifies the overall system architecture but also enables seamless integration with the vehicle’s central control system, perfectly aligning with the electrification and intelligent control trends of modern new energy vehicles.

EMB motors have been widely adopted in high-end new energy vehicles such as the Tesla Model 5 and NIO ET7, where they play a vital role in enhancing braking performance and overall driving comfort. Moreover, their precise control and rapid response capabilities make them a key actuator in advanced driver-assistance systems (ADAS), delivering reliable braking safety for autonomous driving applications.

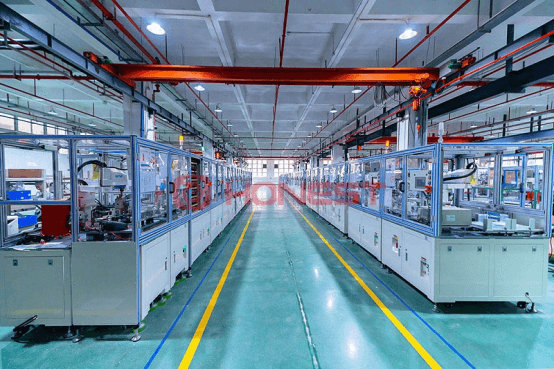

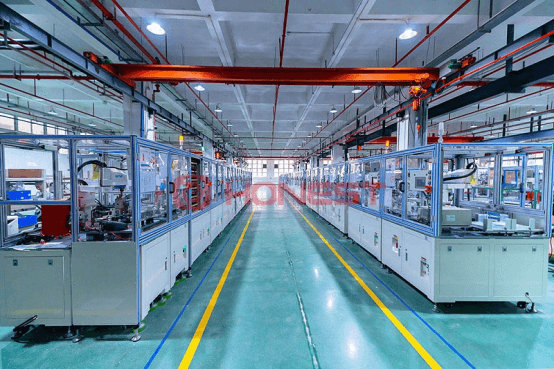

Given the wide-ranging applications and significant advantages of EMB motors, their assembly process demands exceptionally high standards of precision, quality, and efficiency. Due to the complex structure of EMB motors and the necessity for precise integration with vehicle braking systems, high-precision automated assembly equipment is essential to ensure accurate installation of all components. This guarantees the motor’s stability and reliability during vehicle operation. Furthermore, stringent quality control measures are implemented throughout the assembly process, with comprehensive inspections and validations at each stage to eliminate any defects that could compromise braking performance.

As a leading manufacturer of advanced intelligent motor equipment, HONEST Automation is equipped with high-precision robotic arms and specialized automated assembly lines for motor production. These automated systems ensure the accurate installation and efficient assembly of EMB motor components, significantly boosting production efficiency while maintaining consistent and reliable product quality.

In addition, our automated production lines feature a comprehensive quality control system that enforces strict quality checks at every stage, from component assembly to final product inspection. With a robust quality traceability system in place, every step of the production process is meticulously documented, enabling rapid identification and resolution of any issues. This ensures that we consistently deliver high-quality, reliable motor products to our customers.

Driven by the rapid expansion of the new energy vehicle market, the market size for new energy EMB motors is poised for explosive growth. As the technology continues to mature, EMB motors are set to become a pivotal component in the NEV parts market, owing to their advantages in enhancing braking performance, optimizing energy recovery, and improving the overall driving experience. They will play a key role as a driving force behind the development of the new energy vehicle industry.