In modern motor manufacturing, the motor serves as the core component of any drive system, playing a vital role in ensuring stable and reliable operation. Within the motor, the rotor is a key structural element responsible for converting electrical energy into mechanical energy. As automation technology continues to advance, rotor winding machine have become essential equipment for improving production efficiency and ensuring consistent quality in rotor manufacturing.

However, in real-world applications, many customers raise a key question:

"With so many different motor models, can one rotor winding machine handle them all?"

This article aims to address that question by analyzing the technical features and adaptability of rotor winding machines, offering insights for motor manufacturers to make more informed equipment decisions.

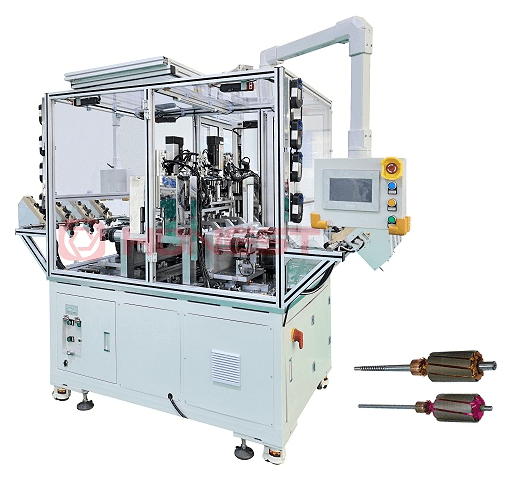

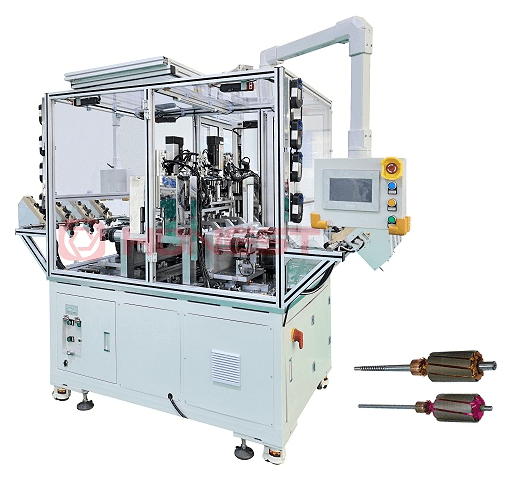

In simple terms, a rotor winding machine is an automated device designed to wind coils onto motor rotors. It not only boosts production efficiency but also ensures consistent and reliable winding quality.

In the past, rotor winding was done manually, resulting in low efficiency and a high risk of errors such as uneven winding and inconsistent coil tension. Today, a high-performance rotor winding machine can complete the winding process for a rotor within minutes. It also offers intelligent features such as tension control, precise wire layering, and wire break detection, significantly improving both production efficiency and product yield.

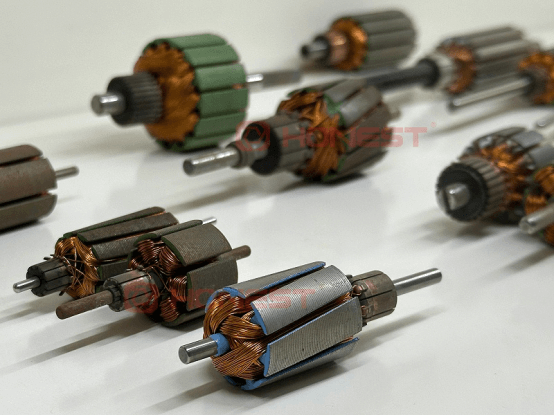

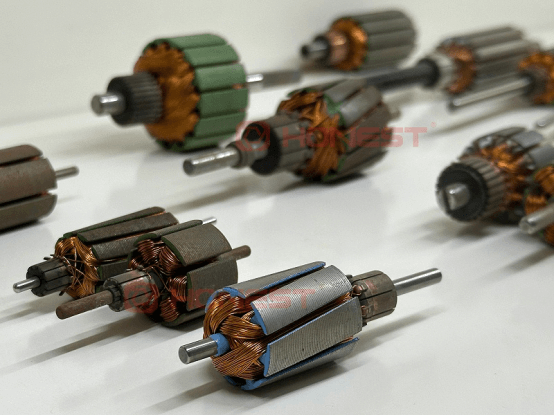

However, not all motor rotors are the same, and not every motor can be processed with a single winding machine. Different types of motors vary in rotor structure, size, and winding methods, which places higher demands on the adaptability of winding equipment.

For example, DC motors feature complex structures with commutators, requiring high winding precision. AC motors have widely distributed windings with a large number of turns, demanding stable and precise tension control. Servo motors are compact with high power density, which calls for efficient space utilization and tightly controlled coil placement. Irregular-shaped rotors with multi-pole structures often require customized fixtures and programming to accommodate their unique winding specifications.

Furthermore, in terms of size, motor rotors vary significantly in diameter and length depending on their power rating and application. For instance, rotors in small household appliances differ greatly in size from those in large industrial motors. Rotor slot designs are diverse, including closed slots, open slots, and semi-closed slots, each imposing different requirements on the winding machines and tooling. Winding methods are equally varied, ranging from single-layer and double-layer windings to wave and lap windings, each with its unique winding characteristics and process demands.

The applicability of rotor winding machines varies depending on the rotor model. For standard motor rotors within the machine’s specified range, winding can usually be completed smoothly. However, there are cases where the machine may not be suitable. These include situations where the rotor size exceeds the maximum or minimum capacity of the machine—such as oversized rotors that cannot fit into the working area; special slot types that do not match the winding machine’s tooling precisely; or winding methods that are incompatible with the machine’s capabilities, resulting in an inability to complete the winding process as required.

Several factors influence the applicability of winding machines. Firstly, the winding machine matters: fully automatic, semi-automatic, and specialized machines each have their focus. Fully automatic winding machines are typically suited for mass production of standard rotor models, while specialized machines are custom-designed for specific rotor types. Secondly, machine specifications such as maximum winding diameter, maximum winding length, and tension adjustment range directly determine the size range of rotors that can be processed. Additionally, whether the machine includes features like slot type adaptation and winding method switching is also a key factor in its adaptability.

The idea that a single winding machine can handle all types of motor models is unrealistic in practical applications. Machines with strong compatibility typically feature modular design, intelligent control, and quick changeover capabilities. However, motor manufacturers should avoid blindly pursuing “all-in-one” equipment and instead make rational choices based on their specific production requirements and product characteristics.

If you are dealing with diverse motor models, frequent changeovers, and complex winding processes, it is advisable to conduct thorough research and testing before selecting a winding machine. Additionally, performing sample winding trials can help verify the machine’s actual performance and adaptability, ensuring a well-informed and effective purchasing decision.

In summary, not every rotor winding machine can accommodate all types of motor models. Compatibility largely depends on the machine’s design structure, control system, tooling, and the manufacturer’s technical support capabilities. As a provider of intelligent motor equipment solutions, leveraging our self-developed winding machine technology and strong technical expertise, we continuously expand our business scope. Our machines offer precise control and adaptability to diverse winding requirements, providing reliable support for motor manufacturing and helping enterprises advance their automation upgrades.