Case Study: EPS Motor Assembly Line Delivered to a Global Leading Automotive Motion Control Company

Customer Profile

The customer is a global leading automotive motion control technology company, specializing in advanced steering systems, drivetrains, and software solutions for future mobility trends such as electrification and autonomous driving. Its product portfolio includes Electric Power Steering (EPS) and Steer-by-Wire (SbW) systems, supplying renowned automakers such as BMW, Ford, GM, and BYD. Headquartered in the United States, the company has a strong global presence with extensive R&D and manufacturing capabilities.

Project Background & Challenges

The customer aimed to improve the production efficiency and product quality of their EPS motors, while reducing labor dependency and operational risks. At the early stage of the project, they faced the following challenges:

EPS motor production involves multiple processes for the stator, rotor, and complete assembly, requiring high-precision assembly and stable operation.

Strict production cycles demand rapid changeovers between multiple product variants.

High standards for quality traceability and error-proofing must be met.

The equipment needs to support modularity and scalability for future upgrades.

The customer sought an automated solution to achieve a highly efficient, reliable, and traceable production system.

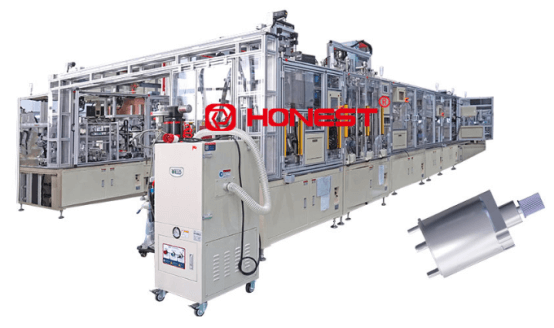

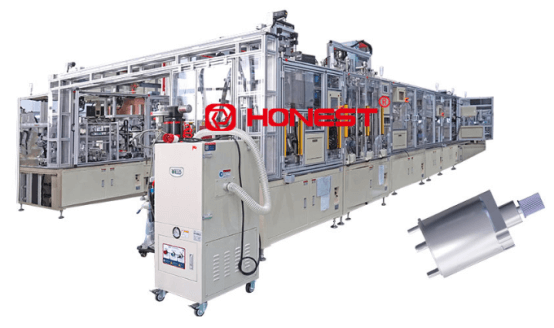

Solution Provided by Honest Automation

Honest Automation provides a complete automated assembly line solution for EPS motors. The production line includes:

Stator assembly section

Rotor assembly section

Motor assembly and packaging section

The entire line consists of approximately 18 machines and employs a hybrid system of conveyor lines and robotic handling to ensure efficient and seamless material flow.

The production line features a modular design, supporting rapid switching between three different EPS motor models, with a single machine changeover taking no more than 20 minutes. The integrated control system allows one-click switching between production models, while enabling full-line data collection and traceability.

Key Equipment Features

Full-process data traceability: The control system records process parameters and material batch information, enabling full traceability throughout the production process.

Error-proof and fail-safe design: Program interlocks, profile-matching jigs, guiding mechanisms, and sensor monitoring ensure production safety and correct operation of each process step.

High integration: Multiple process steps are integrated into compact machines, saving both materials and workshop space.

High production efficiency: Smooth process flow, logical layout, and stable cycle times ensure efficient operation.

User-friendly operation: Ergonomically designed for ease of use, requiring minimal operators.

Performance & Results

Line cycle time: ≤ 29 seconds per unit (winding equipment ≤ 88 seconds)

Changeover time: ≤ 20 minutes

Yield rate: ≥ 98%

Utilization rate: ≥ 90%

Operators: 1 operator for unloading and packaging, 3–4 operators for offline material feeding

Total power: Approx. 360 kW

Control system: PLC + HMI

Line dimensions: Approx. 31 × 7.9 × 2.2 m (with 8 m reserved for testing section)

The complete line operates efficiently and stably, enabling rapid switching between multiple EPS motor models while maintaining high yield.

Why Honest Automation

Extensive experience: Long-term provider of motor automation production lines for global automotive manufacturers.

High reliability: Equipment operates stably over long periods, ensuring high productivity and consistent yield.

Modularity and flexibility: Compatible with multiple product models, supporting rapid changeovers and future upgrades.

Data traceability: The control system ensures full process traceability, facilitating effective quality management.

Application & Scalability

Applicable for automotive electric power steering (EPS) motor production.

Modular design: Can be replicated across other production lines or overseas factories, supporting multiple motor models.

Future-proof: Capable of accommodating future product upgrades and capacity expansion.

High integration and compact design: Saves workshop space and reduces long-term operational costs.

With the full support of Honest Automation, the 150,000-unit-capacity EPS motor production line was successfully delivered to the client’s site: sample units were completed within one month, and stable mass production was achieved within three months. The production line operates reliably and efficiently, with product quality fully meeting the client’s technical specifications. The client expressed high satisfaction with the delivery results and especially awarded Honest Automation the “Outstanding Collaboration Award,” recognizing the exceptional teamwork and trust demonstrated throughout the project.