Case Study Hairpin Stator Production Line Delivered to the Customer Factory

Customer Profile

The customer is a large group enterprise listed among the Global Top 100 IT Companies by Business Weekly, with operations across China, the United States, Japan, Europe, Scotland, and Southeast Asia. It is recognized as one of the world’s leading power supply manufacturers.

Its products are widely applied in power supplies and electronic components, electric vehicle powertrain systems, industrial automation, and building automation, serving a broad range of global markets.

Project Background & Challenges

With the rapid growth of new energy vehicles and high-efficiency electric drive systems, the customer planned to build a highly automated hairpin stator production line for a new project, aiming to achieve both large-scale production and stable, consistent quality.

The key challenges of the project included:

Hairpin stator manufacturing involves complex processes, requiring exceptional equipment stability, consistency, and coordinated control;

Multiple critical process steps demand robust error-proofing, missing-part prevention, and in-line quality monitoring;

The customer sought to achieve unmanned or low-manpower production while maintaining a high yield rate and minimizing future product changeover and expansion costs.

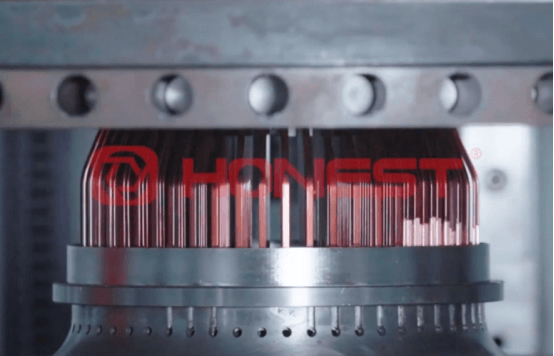

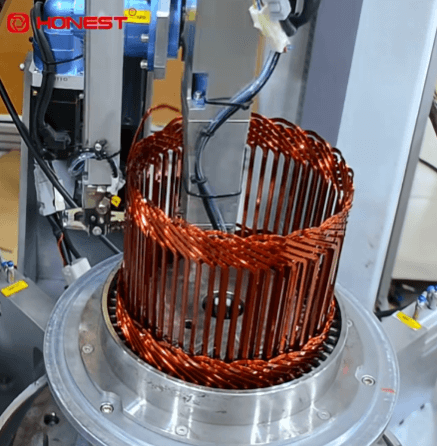

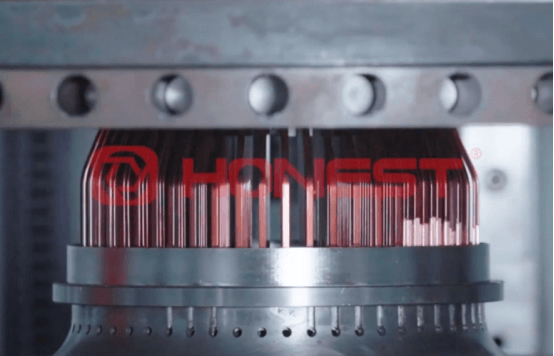

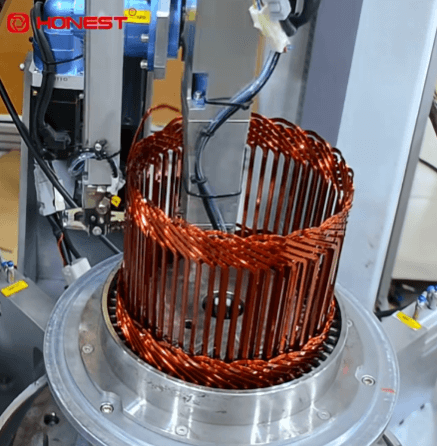

Solution Provided by Honest Automation

In response to these requirements, Honest Automation designed and delivered a customized automated hairpin stator production line. The solution covers hairpin wire forming, stator assembly, key shaping processes, and subsequent assembly operations, all based on a modular and flexible design concept.

The entire line is integrated with an MES system, enabling production visualization, scheduling management, process parameter collection, quality data analysis, and full product traceability. This provides the customer with a smart manufacturing solution that combines high production efficiency with digital management capabilities.

Key Equipment Features

High Level of Automation and Intelligence

Multiple automated stations operate in coordination to ensure continuous and stable production. The line supports unmanned operation, significantly reducing labor dependency.

Comprehensive Quality Monitoring and Error-Proofing

Through sensors, vision inspection systems, and logical interlocks, key processes are monitored in real time, effectively preventing missing or incorrect assembly.

Modular Design with High Flexibility

The equipment supports multiple product specifications. Changeover can be completed through program switching and minor mechanical adjustments, reducing downtime and conversion costs.

Stable and Reliable Forming and Assembly Performance

Optimized for hairpin motor characteristics, the forming and assembly processes deliver high consistency and reliability, meeting long-term mass production requirements.

Performance & Results

Stable cycle time, meeting the planned production capacity

Overall yield rate ≥ 95%

Line utilization rate ≥ 90%

Complete production data recording with full process traceability

After commissioning, the production line has been running reliably, with consistent quality performance, and successfully passed the customer’s internal validation and mass production assessment.

Why Honest Automation

The customer selected Honest Automation based on the following key strengths:

Proven expertise in hairpin stator and rotor assembly technologies

Successful delivery of multiple hairpin stator assembly lines, hairpin wire forming machines, and related equipment

A dedicated technical team deeply rooted in the hairpin motor industry, with core engineers possessing decades of experience

A stable R&D and engineering team capable of providing continuous process support and solution optimization

A responsive and well-structured after-sales service system ensuring long-term stable operation

Application & Scalability

This solution is well-suited for hairpin motors and other applications with high demands on automation, quality consistency, and digital production management.

Thanks to its modular architecture and standardized interfaces, the production line offers excellent scalability and replicability. It can be quickly adapted to different product specifications and capacity requirements, supporting the customer’s future expansion and long-term manufacturing strategy.

In addition to this hairpin stator assembly line, Honest Automation also supplied the customer with hairpin wire forming machines, impregnation (trickle varnish) machines, as well as another hairpin stator assembly line based on a different process route. The stators produced on this additional line are larger in size and more complex in structure, with significantly higher requirements for assembly accuracy, process coordination, and equipment stability. This project further demonstrates Honest Automation’s strong technical expertise and engineering capability in hairpin stator manufacturing and assembly.

Leveraging its deep understanding of hairpin motor technology, Honest Automation is able to provide a full range of solutions, including standalone machines, semi-automatic production lines, fully automated hairpin stator assembly lines, as well as motor prototyping and process validation services. These flexible solutions help customers accelerate new product introduction, reduce development and ramp-up risks, and build intelligent manufacturing systems with long-term scalability.