Fan motors are essential components in ceiling fans, table fans, and exhaust fans, ensuring smooth operation and energy efficiency. Proper winding is crucial for the performance and durability of these motors. This article provides a detailed overview of fan motor winding, including manual winding techniques, testing procedures, and the advantages of automatic winding machines.

1. What is Fan Motor Winding?

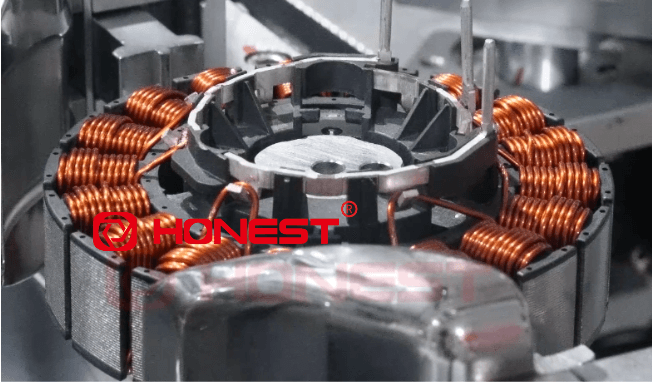

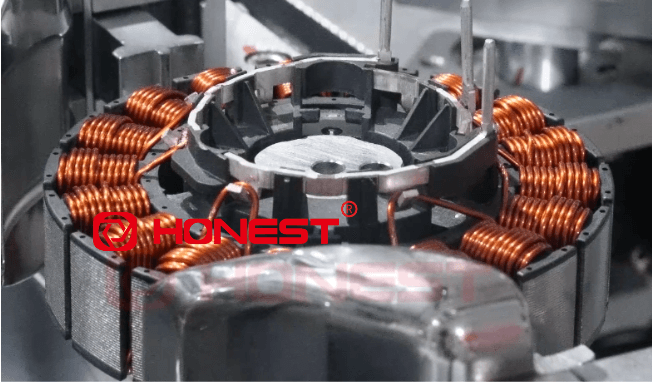

Fan motor winding refers to the process of coiling copper or aluminum wire around the stator or rotor to create an electromagnetic field. This process is critical for converting electrical energy into mechanical rotation, enabling the fan blades to spin. Windings can be categorized into single-phase winding (used in residential fans) and three-phase winding (common in industrial applications). Additionally, with the rise of energy-efficient solutions, BLDC fan motor winding has gained popularity due to its reduced power consumption and enhanced performance.

2. How to Manually Wind a Fan Motor?

Manual winding requires precision to ensure uniformity and optimal electrical characteristics. The basic steps include:

Step 1: Preparing the wire – Selecting the right gauge and insulation type.

Step 2: Coil formation – Wrapping the wire around the stator slots according to the winding diagram.

Step 3: Insulation and varnishing – Applying insulating materials to prevent short circuits.

Step 4: Connection and assembly – Connecting the winding ends to the terminal points before reassembling the motor.

While manual winding is cost-effective for small-scale production or repairs, it is labor-intensive and prone to inconsistencies.

3. How to Check Fan Winding?

To ensure proper functionality, the following tests are commonly used:

Multimeter Resistance Test: Measures coil resistance to detect breaks or shorts.

Insulation Resistance Test: Ensures there are no electrical leakages.

Continuity Test: Confirms an uninterrupted electrical path.

Hi-Pot Test: Verifies high-voltage insulation strength.

Early detection of winding faults prevents operational failures and extends the motor’s lifespan.

4. The Rise of Automatic Fan Winding Machines

Modern fan winding automatic machines have revolutionized the manufacturing process by increasing efficiency and consistency. These machines offer several advantages:

Higher precision – Eliminates human errors in coil placement and tensioning.

Increased productivity – Automates repetitive tasks, boosting output.

Enhanced quality control – Ensures uniform insulation and reduces failures.

5. Automatic Ceiling Fan Winding Machine – Features and Benefits

For large-scale manufacturers, automatic ceiling fan winding machines provide:

Programmable winding patterns for different motor specifications.

High-speed operation to handle bulk production efficiently.

Minimal material wastage due to precise wire handling.

These machines streamline the production of high-performance ceiling fan motors, catering to increasing market demands.

6. BLDC Fan Motor Winding – A New Era in Efficiency

Brushless DC (BLDC) fan motors are gaining traction due to their energy efficiency, low noise levels, and extended lifespan. Automated winding solutions for BLDC motors focus on:

Compact and lightweight coil arrangements.

Reduced copper losses.

Superior thermal management.

Investing in BLDC-specific winding machines ensures manufacturers stay ahead in the transition to eco-friendly fan motors.

7. Fan Motor Winding Machine Price and Selection Tips

The price of a fan motor winding machine varies based on features, automation level, and production capacity. Key considerations when purchasing include:

Machine type (semi-automatic vs. fully automatic).

Customization capabilities for different motor specifications.

After-sales support and spare parts availability.

Cost vs. return on investment – balancing affordability with performance.

Choosing the right winding method and equipment is critical for ensuring fan motor efficiency and longevity. While manual winding remains relevant for small-scale applications, investing in automatic fan winding machines enhances productivity and quality. With the growing adoption of BLDC fan motors, manufacturers should consider advanced winding solutions to meet future market demands.

HONEST has extensive experience in providing motor automation solutions, including the automotive and truck condenser fan motor assembly line. We offer customized solutions tailored to industry needs. For inquiries about high-quality automatic fan motor winding machines, contact HONEST – your trusted partner in motor automation solutions.