In today’s fast-evolving manufacturing landscape, one thing is clear: adaptability is the new productivity. Traditional fixed production lines, while efficient in high-volume, single-product manufacturing, are struggling to keep pace with growing demands for customization, shorter lead times, and rapid product iteration. This is where flexible automation and flexible production lines come into play—reshaping the very foundation of scalable, smart manufacturing.

1. What Is Flexible Automation and Why Does It Matter?

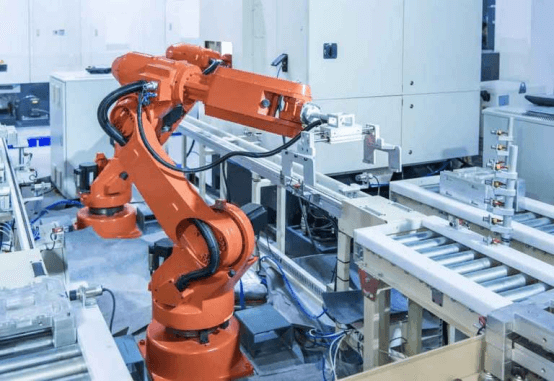

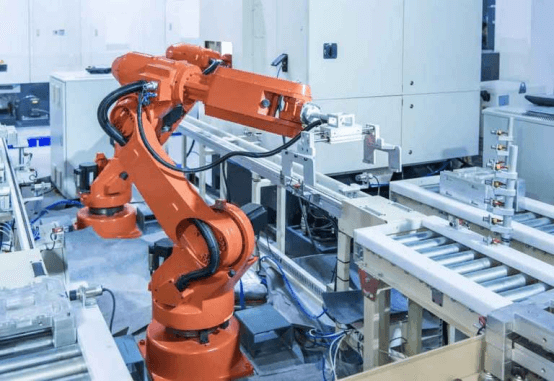

Flexible automation refers to automated systems that can be quickly reconfigured to produce different products or perform various tasks, with minimal downtime or manual intervention. Unlike hard automation—which is designed for high-volume repetition—flexible systems are built to handle variety, change, and uncertainty.

Flexible production lines, often powered by software-defined control systems and modular machines, are the physical embodiment of this concept. They are designed for rapid model changeovers, high mix/low volume (HMLV) production, and seamless integration with upstream and downstream processes.

In an era of increasing product diversification and shorter product life cycles, this adaptability isn't just beneficial—it’s essential.

2. Key Features of Flexible Automation Systems

The strength of flexible automation lies in a few core characteristics:

Reconfigurability: Equipment and software can be quickly reprogrammed or adjusted to produce different variants or new models.

Modularity: Production cells are composed of independent, interchangeable modules that can be added, removed, or re-sequenced.

Software-Driven Control: Advanced manufacturing execution systems (MES) and programmable logic controllers (PLCs) allow logic and process control to be updated without mechanical changes.

System Integration: Connectivity with ERP/MES enables real-time production visibility, resource planning, and traceability.

These capabilities empower manufacturers to produce a broader variety of products using the same production infrastructure, reducing capital investment and boosting ROI.

3. Benefits of Flexible Production Lines

For engineers and operations leaders, the shift toward flexible production lines offers numerous advantages:

Higher Utilization & Reduced Downtime

Production lines can switch between models or product families with minimal retooling, slashing changeover times and boosting equipment utilization.

Lower Total Cost of Ownership

Instead of investing in multiple dedicated lines, manufacturers can deploy one reconfigurable line, significantly reducing equipment and floor space costs.

Rapid Response to Market Changes

With the ability to quickly adapt to new designs or shifting customer demands, businesses can remain competitive in fast-moving markets.

Scalable and Future-Proof

Flexible lines can evolve with the product roadmap, making them ideal for R&D-intensive industries or phased product launches.

4. Practical Applications Across Industries

Flexible automation isn't just a concept—it’s actively transforming production in multiple sectors:

Automotive motors: Manufacturers of EPS motors, oil pump motors, and drive motors are adopting flexible lines that can handle multiple stator and rotor variants without redesign.

Consumer electronics: Assembly lines for wearables and IoT devices rely on reconfigurable platforms to handle frequent product launches.

Medical devices: Manufacturers benefit from precision, compliance, and the ability to switch quickly between configurations.

Humanoid robotics: With evolving designs and low initial volumes, flexible automation is critical to accelerating time-to-market.

5. Technology Enablers for Flexible Automation

Implementing flexible automation depends on an integrated set of advanced technologies:

Collaborative Robots (Cobots) and AGVs/AMRs: Enable mobile, multi-purpose work cells and dynamic material handling.

Universal Fixtures and Smart Tooling: Allow rapid part changeover and compatibility across product families.

AI & Machine Learning: Optimize scheduling, detect anomalies, and adapt parameters for different product variants.

Digital Twins & Simulation: Facilitate virtual commissioning and fast deployment without physical trial-and-error.

These technologies form the backbone of an intelligent, responsive production system that engineers can monitor, adapt, and continuously improve.

6. Case Study: How HONEST Automation Delivers Flexible Motor Assembly Solutions

At HONEST Automation, we specialize in delivering modular, scalable, and software-defined motor production line tailored to automotive and robotics applications. One of our recent successes involved designing a multi-model stator winding and rotor assembly line that:

Reduced changeover time from 4 hours to 30 minutes

Enabled the production of 6 different motor types on a single line

Achieved >98% equipment utilization rate

Integrated seamlessly with the customer’s MES and quality traceability system

This solution empowered the client to scale from prototype to mass production without re-investing in new equipment—an example of true engineering flexibility in action.

7. The Road Ahead: Embracing the Shift Toward Flexibility

As global competition intensifies and product complexity rises, flexible automation is no longer a luxury—it’s a necessity. For engineers, the shift to flexible systems opens up exciting opportunities to:

Redesign traditional production with modular, intelligent systems

Improve cost-efficiency across product life cycles

Future-proof production investments through scalability and adaptability

Forward-thinking manufacturers that embrace flexibility today will be best positioned to lead in the smart manufacturing revolution of tomorrow.

Are You Ready to Build Your Flexible Production Line?

At HONEST Automation, we partner with engineers and manufacturers to create tailored, high-efficiency automation solutions. Whether you're producing EV motors, precision actuators, or robotic components, we can help you transition to a flexible, intelligent, and scalable production environment.

Let’s engineer the future—flexibly.