We have compiled some questions about stator assembly line you may have. If you have any other questions, please feel free to contact us and we will answer them in detail.

Q1: For the same forming machine, how does the straightening system deal with the differences in straightening effects caused by the differences in copper wires between different batches of the same model?

A: Different batches do have some differences in the straightening effect of copper wires. The wire-making machine transfers U-pin with both feet fixed, and the wire insertion clamp opening is larger, which can eliminate this difference. However, the actual production process has not been found to be affected by batch differences.

Q2: For the current variety of paint removal processes, such as laser paint removal, milling paint removal, stamping paint removal, mechanical paint removal, and so on, how does HONEST Automation choose? What are the considerations for selecting the process?

A: 1. Laser paint removal: simple model change, less paint removal, small gaps in copper wires during welding, and high cost.

2. Milling to remove paint: simple model change, less paint removal, small gaps in copper wires during welding, milling cutters need to be replaced regularly, about 70,000 times, and the cost is lower than laser paint removal;

3. Punching to remove paint: changing the model requires changing the tool, which requires a lot of paint removal. The gap between the copper wires is large during welding, and the tool needs to be replaced regularly. It is economical and price-effective.

Q3: How does HONEST Automation ensure accuracy in the length direction when cutting copper wire? What level of accuracy can it achieve? How does HONEST Automation consider the accuracy of length dimensions? Is there a recommended value? what are the reasons?

A: First, the length of copper wire cutting is guaranteed by an external encoder, and the accuracy can be 500mm ±0.3mm. And because there is a flattening process, the length is guaranteed to be within ±0.5mm and will not have a significant impact on subsequent workstations.

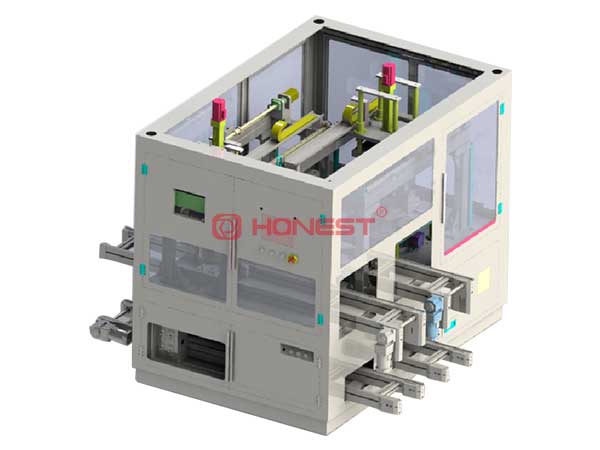

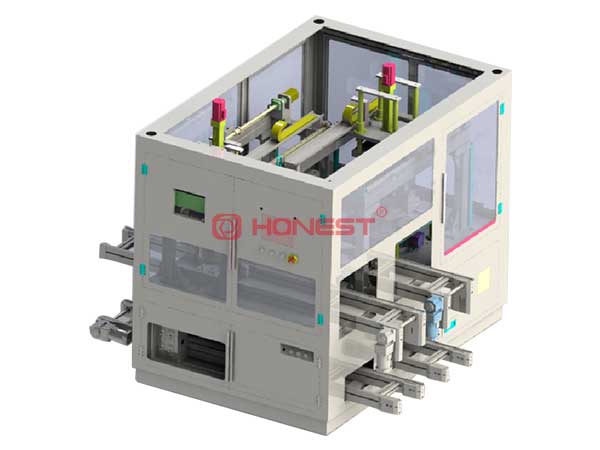

(The picture above shows HONEST Automation's flat wire stator flattening machine)

Q4: How does HONEST Automation ensure the accuracy of repetitive positioning for each hairpin when the copper wire is transferred from 2D to 3D molding?

A: At present, we mainly promote the hybrid molds, which are first made into 3D and then U-shaped. The copper wires are limited during molding, and the molds have guides and limits to ensure the positioning accuracy of the card issuance.

Q5: How does HONEST Automation ensure that defective pieces of copper wire varnish damage and electrical weaknesses in the varnish itself, which may occur during the molding process, do not find their way into the assembled winding?

A: The wire-making machine has a voltage resistance test, and 100% of the copper wire is tested by carbon brushes so that defective parts are automatically discharged.

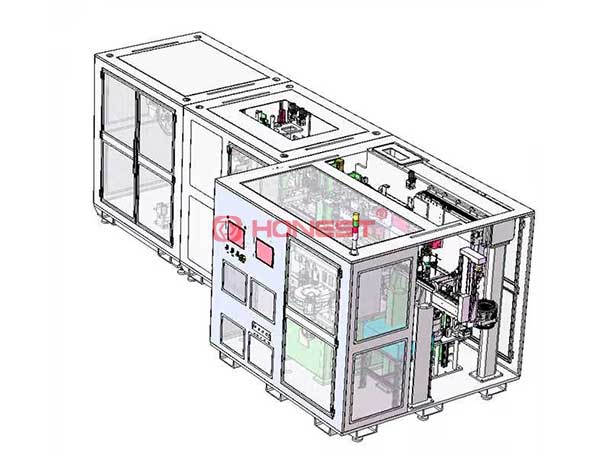

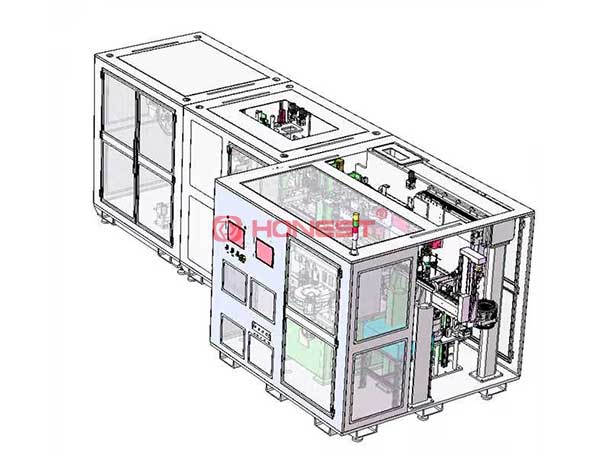

(The picture above shows HONEST Automation's flat wire stator automatic wire making machine)

Q6: How does HONEST Automation consider how to quickly change molds or balance the CT between each molding machine when the number of card types exceeds what one molding machine can accommodate?

A: The wire-forming machine is equipped with a mold warehouse that can store more than 20 types of molds. The wire-forming machine is compatible with all wire types on one stator.

Q7: How does HONEST Automation evaluate the molding effect of hairpins? How does HONEST Automation consider the difference between the molded size and the design model?

A: 1. With a hole fixture, check whether the U-pin can fall freely into the hole;

2. Use the profiling jig to check whether the U-pin can fit the profiling jig;

3. There is a 3D profile scanner in the quality control room, which can scan the profile of the U-pin and compare it with the digital model;

There will be some differences between the size of the formed U-pin and the digital model. The difference in the 3D outline of the shoulder is small, and the difference in the straight line segment will be more obvious. However, the influence of the straight line segment on the wire insertion can be eliminated through the guide positioning of the wire insertion clamp.

Q8: By what means does HONEST Automation ensure the consistency of molding by the forming machine? How much deviation can be guaranteed between hairpins of the same type?

A: The consistency of the forming machine is guaranteed by the mold. After the mold is ground and debugged on-site, the consistency is still very good. The deviation between the same hairpin needs to be evaluated based on the specific line type. The span and the number of layers of U-pin and the length of the straight section both have an impact on the consistency of the molding.

According to experience, the consistency above the shoulder can be within 0.2mm, and the consistency of the straight section can be within 0.5mm, and it should be evaluated specifically based on the specific line type.