As the greenhouse effect continues to strengthen, reducing greenhouse gas emissions, developing renewable energy, improving energy efficiency, and promoting industrial structure transformation and upgrading are the directions that every country in the world is working towards.

Various international organizations and countries have proposed corresponding policies. For example, the European Union has proposed the “Fit for 55” plan to reduce greenhouse gas emissions by 55% by 2023 compared with 1990 levels. The United States has also announced a “net-zero emissions” goal. It plans to achieve carbon neutrality by 2050. The Chinese government has also proposed a “dual carbon” goal, planning to achieve a carbon peak by 2030 and achieve carbon neutrality by 2060. HONEST Automation actively responded to the national policies and developed a variety of new energy drive motor productions to contribute to environmental protection.

Definition of new energy:

New energy refers to energy sources that exist in nature and can be continuously regenerated, inexhaustible, and inexhaustible, including solar energy, wind energy, hydro energy, geothermal energy, biological functions, ocean energy, and so on.

Advantages of new energy:

A. Renewable: it can be constantly regenerated and there is no risk of depletion.

B. Clean: it does not produce pollution in the process of use, which is friendly to the environment.

C. Low carbon: it does not produce a large amount of greenhouse gases such as carbon dioxide during use, which is conducive to combating climate change.

D. Efficient: the conversion efficiency of new energy sources is constantly improving, which can effectively utilize energy resources.

Applications of new energy

New energy is widely used in various aspects due to the above advantages. Among them, there are three main applications in the motor industry:

A. New energy motor: it refers to a motor that uses new energy as a power source, including wind turbines, solar generators, fuel cell generators, and so on;

B. New energy motor drive system: it is an application system for new energy motors, which mainly includes motors, electronic controls, transmissions, and so on. The motor is the core component and control system of the new energy motor drive system, and the transmission is the power transmission system of the new energy motor drive system;

C. New energy motor control system: it is an important part of the new energy motor drive system and is mainly responsible for the starting, speed regulation, braking, and other control of the motor. The performance of the new energy motor control system directly affects the performance of the new energy motor.

Among them, the drive motor is an important link in the new energy industry. The motor drive control system is the main execution structure of the new energy vehicle. The drive motor and its control system are one of the core components of the new energy vehicles. Its driving characteristics directly determine the vehicle’s driving characteristics. The main performance indicators such as climbing, acceleration, and top speed are important components of electric vehicles.

Next, HONEST Automation’s solutions for new energy drive motors will be introduced in detail.

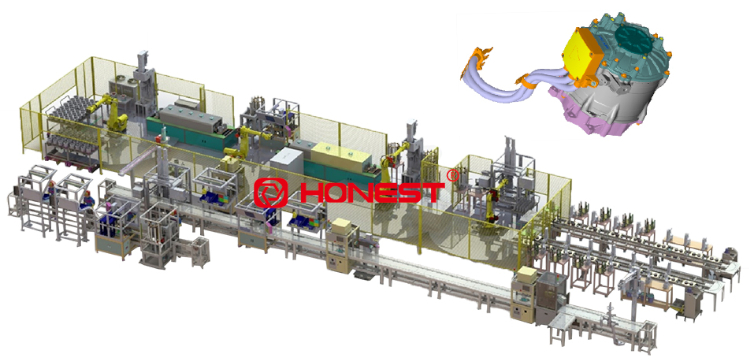

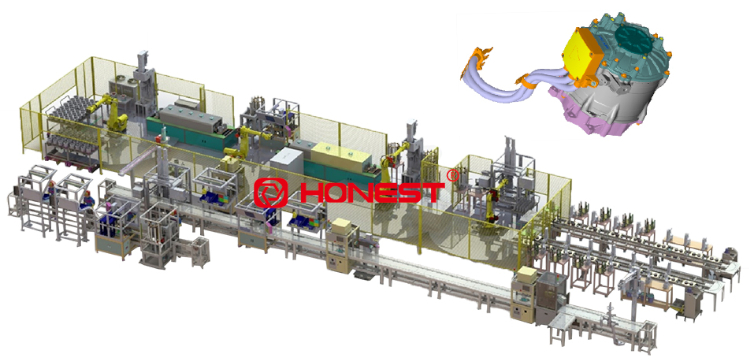

A. New Energy Vehicle Drive Motor Assembly Equipment

Equipment introduction: its processes include: rotor press-fitting and rear bearing, rotary rotor and pressure plate press-fitting, end cover installation positioning pins and elastic wave pads, end cover bearing chamber heating, end cover, and rotor assembly, and main housing installation front oil retaining ring, casing heating, electrical performance testing, final tightening and fixing of the main reduction gear, motor assembly cooling, O-ring, casing glue coating, cooler installation, filter press installation, filling plug, air tightness test, product appearance inspection, packaging, storage, and so on.

Equipment parameters:

1. Production efficiency: 100s/pcs;

2. Qualification rate: 99.9%;

3. Voltage: 80V/220V;

4. Power:750KW;

5. Replacement time: 30min

6. Physical dimension: 58(L) x 20(W) x 2.8(H)m

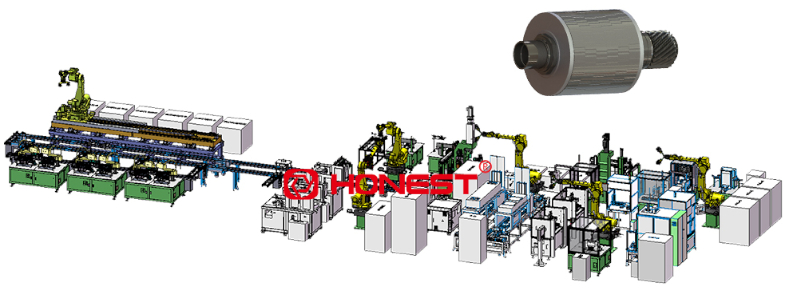

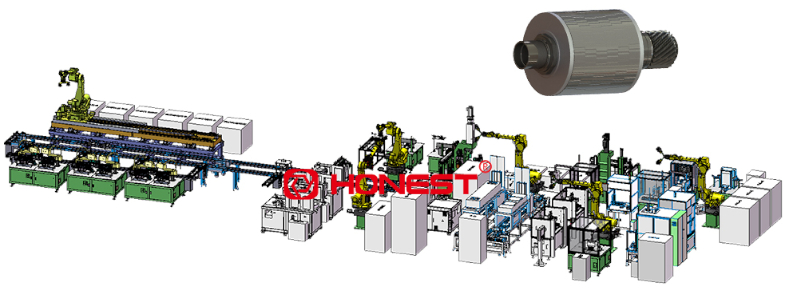

B. Drive Motor Rotor Production Line

Equipment introduction: The new energy drive motor rotor production line adopts the MES manufacturing execution system to provide enterprise with management modules including manufacturing data management, production process control, underlying data integration analysis, and upper-level data integration and decomposition, to create a solid, reliable, comprehensive and feasible manufacturing for enterprises collaborative management platform. This project is used to assemble new energy vehicle drive motor rotors. The whole line adopts a modular design, robots automatically load and unload materials, and the production line is highly flexible, providing a one-stop solution for the manufacture of drive motors.

Equipment parameters:

1. Efficiency: 128s/pcs;

2. Qualification rate:98%;

3. Voltage:380V;

4. Physical dimension:52000(L)x30000(W)x2800(H)mm.

C. Electric Vehicles Motor Rotor Assembly Line

Equipment introduction: the equipment is used for the assembly of four rotors of air conditioner compressors of new energy vehicles. The assembly process includes rivet length detection, rivet assembly, installing upper counterweight disc, upper anti-damage plate assembly, iron core assembly, magnetic steel assembly, installing bottom counterweight disc, rivet flanging diameter detection, crankshaft pressing, crank pin pressing NG removal, 4axis robot arms discharging, and so on.

Equipment parameters:

1. Production efficiency:12pcs/hour;

2. Power:13.2kw;

3. Gas pressure:0.4-0.6MPa;

4. Power supply:380V

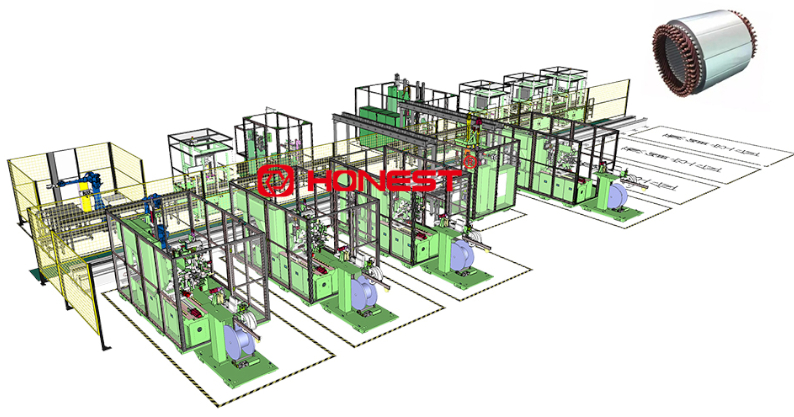

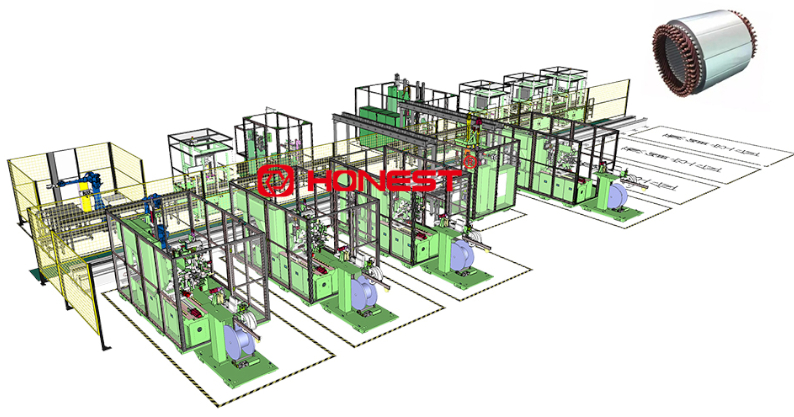

D. New Energy Hairpin Motor Stator Assembly Line

Equipment introduction: the new energy drive motor production line is suitable for the production of the hairpin motor stator. It can be applied to new energy drive motors, generators, and other areas. The standard parts of all lines adopt the world-famous brands. The servo motor applies bus control. Key parts all apply precision equipment self-processing. This production line can realize fully automatic production of three-line six-layer, four-line eight-layer, and five-line ten-layer, up to 12 layers can be made. Intelligent function: production data real-time traceability. Upload and deliver, connect with EMS, key part life management, and face recognition system.

Equipment parameters:

1. Efficiency: 30-50pcs/hour;

2. Voltage: AC three-phase 380V;

3. Air pressure:0.4-0.6MPa;

4. Pass rate:>99%;

5. Power:450KW;

6. Full-day time utilization:>95%;

7. Physical dimension:12(L)x9(w)x2.5(H)m

The above production lines and equipment have both their unique advantages and common advantages.

The common advantages are briefly as follows:

1. The standard parts used across the entire line are from internationally renowned brands and are highly reliable;

2. Intelligent functions: real-time tracing of production data, uploading and distributing, and docking with EMS; life management of key components; facial recognition system;

3. Digitally manage production lines and bind process data;

4. High efficiency and less waste of raw materials during operation;

5. Non-standardized customization can be carried out according to customer needs.