As the global automotive industry evolves, both electric vehicles (EVs) and internal combustion engine (ICE) vehicles continue to rely on high-performance generator motors. These motors serve distinct yet critical functions—from powering auxiliary systems to supporting regenerative braking in EVs, or generating electrical energy in traditional ICE vehicles.

With increasing pressure on OEMs and Tier-1 suppliers to deliver efficient, reliable, and cost-effective solutions, the assembly of generator motors has become a key focus area for process optimization. At HONEST Automation, we offer intelligent assembly solutions tailored to meet the specific demands of both EV and ICE generator motors.

Generator Motor: Differences Between EV & ICE Applications

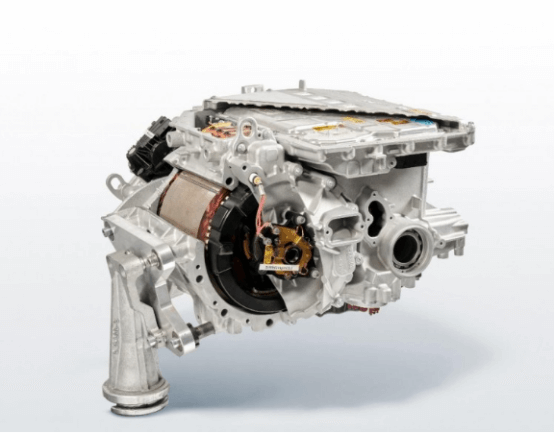

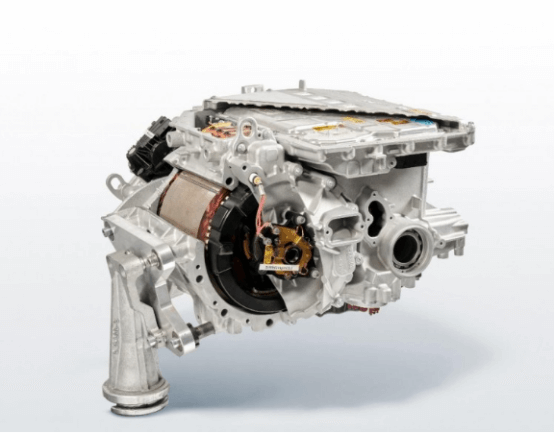

While both EV and ICE vehicles use generator motors, the design and function vary significantly.

In EVs, generator motors often serve as auxiliary power units or support regenerative braking systems. These motors typically operate at higher voltages, require tighter thermal control, and demand more compact, lightweight designs.

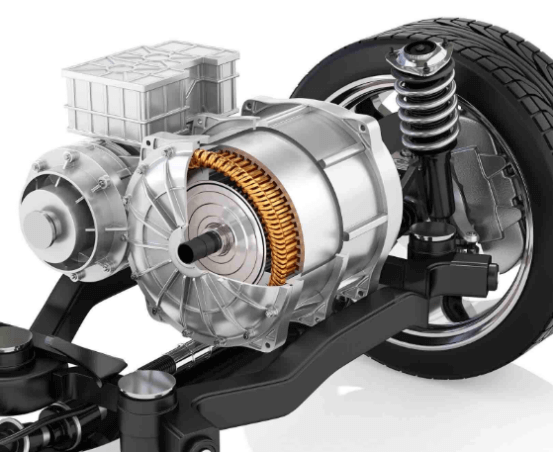

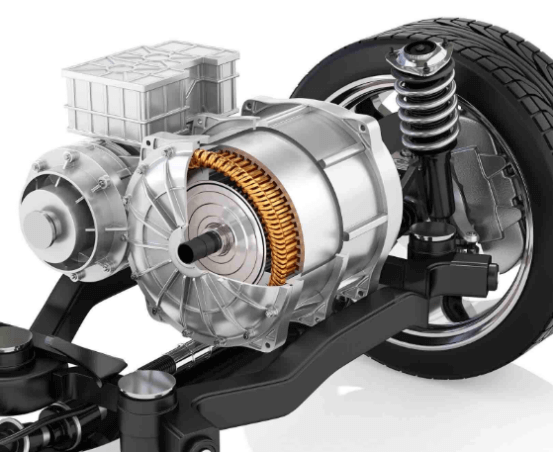

In ICE vehicles, the generator—commonly an alternator—converts mechanical energy into electrical energy to charge the battery and power systems like lighting, infotainment, and climate control. These motors must withstand higher mechanical loads and prolonged operation under variable conditions.

Understanding these differences is crucial for designing and assembling motors that meet performance, durability, and efficiency targets.

Key Challenges in Generator Motor Assembly

The transition to more complex, multi-platform vehicle architectures brings several challenges to generator motor assembly:

Precision Requirements: Generator motors require exact alignment, consistent winding tension, and accurate rotor/stator integration to achieve performance standards.

Product Variability: Manufacturers often need to produce multiple motor variants on the same line, calling for flexible, reconfigurable assembly systems.

High Quality Standards: The need for zero-defect production and traceability is essential, especially for Tier-1 suppliers delivering directly to OEMs.

Cost and Labor Optimization: Balancing high automation with cost-effective production and minimal manual intervention is a top priority.

HONEST Automation Smart Assembly Solutions

At HONEST Automation, we specialize in fully automated and semi-automated generator motor assembly lines that cater to both EV and ICE platforms. Our solutions are engineered to overcome industry challenges with advanced technology and customizable configurations.

Key Features Include:

Modular Design: Adaptable for different motor sizes, winding types (concentrated or distributed), and rotor-stator structures, enabling flexible production.

Integrated Processes: Our lines cover coil winding, insertion, soldering, laser welding, rotor assembly, balancing, and end-of-line testing—all within a single automated flow.

Real-time Inspection: Built-in vision systems, torque and resistance measurement, and high-voltage testing ensure consistent quality with full traceability.

Smart Changeover: Quick tooling and program switches support multi-model production with minimal downtime.

Whether you are producing compact 12V generators for ICE vehicles or high-efficiency 48V units for mild hybrid or full EV applications, our equipment ensures precise, repeatable, and scalable assembly.

Benefits for OEMs and Tier-1 Suppliers

By implementing HONEST's generator motor assembly solutions, automotive manufacturers and component suppliers gain:

Higher Productivity: Reduced cycle times and continuous operation improve throughput.

Improved Product Quality: Automated processes and inline testing reduce defects and warranty claims.

Lower Operational Costs: Fewer manual processes and optimized energy usage lead to better ROI.

Global Standards Compliance: Our systems are designed to meet IATF 16949, ISO 9001, CE, and other international quality and safety certifications.

Future-ready Flexibility: As EV and ICE platforms coexist, our modular design philosophy ensures long-term adaptability.

Case Study: Proven Results in EV Motor Production

A world-leading Japanese automobile company used the Non-Cutting Hairpin Stator Twisting Machine of honest automation to change the traditional process and greatly reduce the cost of motor stator manufacturing. The equipment occupies a small area and has high flexibility. It can process 4-layer, 6-layer and 8-layer wires.

As vehicle electrification accelerates and ICE platforms continue to evolve, generator motors remain a vital component across the automotive landscape. To meet the growing demand for precision, flexibility, and efficiency, smart assembly solutions are no longer optional—they're essential.

At HONEST Automation, we’re committed to helping global automotive and auto parts manufacturers build better motors, faster. Contact us today for a customized solution if you're looking for a trusted partner to optimize your generator motor production—whether for EV, ICE, or hybrid applications.