As the demand for high-performance electric motors continues to rise, especially in the electric vehicle (EV) industry, manufacturers face growing challenges in meeting both efficiency and customization requirements. Segmented stator winding has emerged as a powerful solution—but not all winding machines are built the same.

At HONEST Automation, we’ve worked closely with global motor manufacturers and discovered a key issue: while the advantages of segmented stator technology are widely acknowledged, many companies struggle with finding the right winding equipment to fully harness its potential.

The Challenge: Diverse Winding Needs, One Market Gap

EV motor manufacturers today operate in a rapidly evolving environment. Some prioritize high-precision winding for complex designs, while others focus on ramping up production speed to replace traditional manual labor. However, many conventional equipment providers offer limited flexibility. As a result, manufacturers are often forced to compromise between performance, efficiency, and scalability.

This challenge is especially acute when it comes to segmented stator winding, where different winding types—single-slot, dual-slot, 3-slot, and even 4-slot assemblies—require tailored solutions. A one-size-fits-all approach simply doesn’t work.

Why Segmented Stator Matters for EV Motors

Compared to traditional inner or outer winding methods, segmented stator winding involves pre-winding individual segments before assembling them into a complete stator. This method:

Improves fill factor and power density

Enables precise winding control

Adapts better to complex multi-pole stator designs

Minimizes conductor damage for specialty wires

Enhances thermal and electromagnetic performance

However, if not properly implemented, this technique can also bring new production headaches.

Case Study: An EV Drive Motor Manufacturer's Struggle

One of our EV clients—an established supplier of high-performance drive motors—faced exactly this situation. They were developing a new motor featuring a multi-segment stator structure. Yet their existing winding equipment, designed for traditional integrated stators, lacked the accuracy and flexibility to handle segmented winding.

The challenges included:

Winding displacement and uneven turns, due to insufficient path control

Manual insulation paper application, which led to air bubbles and folds

Inconsistent glue dispensing, causing insulation failure or component misalignment

High rejection rate, affecting throughput and reliability

In short, the lack of automation and precision in their existing setup was limiting both product quality and production scale.

Key Production Pain Points

From this case and others, we identified three critical bottlenecks in segmented stator winding:

1. Varied winding needs across different segments – Each winding type requires a unique machine structure and control system.

2. Low insulation paper efficiency – Manual application is time-consuming and inconsistent.

3. Uncontrolled glue application – Manual dispensing results in uneven coverage, lowering insulation reliability.

These issues are not just process inefficiencies—they impact final motor performance, quality control, and long-term competitiveness.

HONEST’s Smart Solutions for Segmented Stator Winding

At HONEST Automation, we’ve invested years into refining segmented stator winding technology across multiple generations of equipment. Our tailored solutions address the pain points directly:

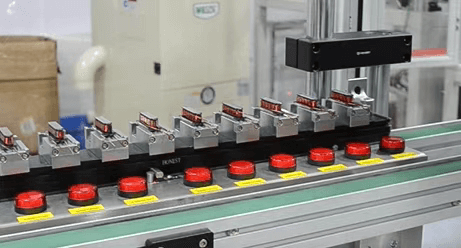

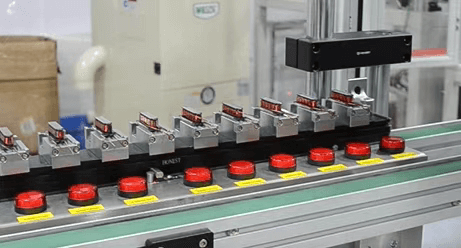

Modular Winding Equipment for All Segment Types

Our machines support single-slot, dual-slot, triple-slot, and quad-slot winding. With flexible configuration options—such as 2 or 3-station designs and long/short span types—customers can choose precisely what fits their application. For example, our 4th Gen dual-slot machine integrates shaping functions to ensure consistent coil form and motor performance.

Automatic Insulation Paper Feeding

Manual paper application is replaced with precision automation. Our machines integrate robotic arms and intelligent control to handle insulation feeding, positioning, and pressing. This not only improves quality but also significantly increases productivity.

UV Glue Dispensing and Curing System

To solve manual glue problems, our machines feature automated UV glue application with controlled flow rate and targeted curing. The result: uniform adhesion, enhanced insulation reliability, and reduced labor costs.

Built for the Future of EV Motors

From modular design to smart automation, HONEST Automation’s segmented stator winding solutions empower EV makers to meet growing demands for performance, customization, and cost-efficiency. Our commitment to innovation and customer-driven R&D has led us from Gen 1 to Gen 4 machines—each more reliable, precise, and intelligent than the last.

If you're exploring high-efficiency segmented stator winding or require non-standard customization, we warmly invite you to visit our factory, collaborate with our engineers, and discover how HONEST Automation can support your growth in the next era of motor manufacturing.