Recently, during the Technology Achievement Evaluation Conference organized by the Shenzhen Association of Intelligent Manufacturing, Honest Automation successfully passed the expert review for its independently developed project, "R&D of New Energy Vehicle Hairpin Motor Production Line Technology."

At the meeting, Mr. Liao, Deputy General Manager of Honest Automation, presented a detailed report covering the project’s development background, core technological breakthroughs, and key innovations. After a rigorous, multi-dimensional evaluation, the expert panel unanimously concluded that the project has reached a “domestic leading level” within the industry.

This recognition not only highlights Honest Automation’s continued innovation in core equipment for Electric Vehicles but also marks a significant milestone for China’s efforts to break the international monopoly on high-end hairpin motor production lines. It represents a solid and meaningful step toward achieving independent control over critical segments of the industry value chain.

1. Strategic Momentum: Policy Support and Industry Transformation Driving Technological Innovation

China’s new energy vehicle (NEV) industry has entered a new phase—shifting from rapid expansion to high-quality development, and from focusing on vehicle manufacturing to strengthening the entire supply chain. National strategic documents, including the New Energy Vehicle Industry Development Plan (2021–2035), clearly emphasize the goal of enhancing the technological capabilities of core components such as traction motors. This top-level guidance provides strong policy support and new development opportunities for the industrialization and advancement of hairpin (flat-wire) motor technologies.

At the same time, under China’s national “dual-carbon” (carbon peak and carbon neutrality) strategy, hairpin motors have become a key technology enabling the NEV sector’s transition toward greater energy efficiency and lower emissions. Thanks to their superior performance in reducing losses and improving power efficiency, hairpin motors are now recognized as one of the core technologies accelerating the NEV industry’s move toward a greener and more sustainable future.

2. Market-Driven Demand: Technical Advantages Accelerating Industry Transformation

With the rapid rise in NEV penetration and consumers’ growing expectations for performance, the market now demands higher power density, efficiency, reliability, and lightweight design from traction motors.

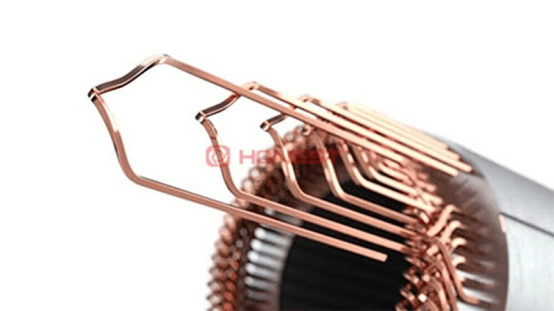

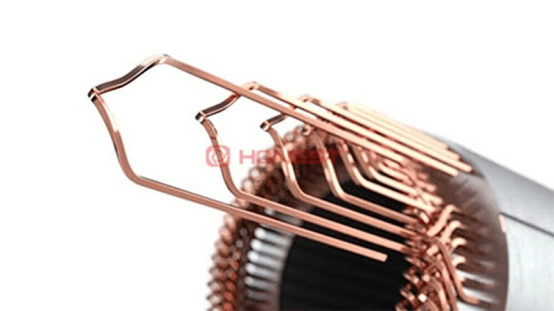

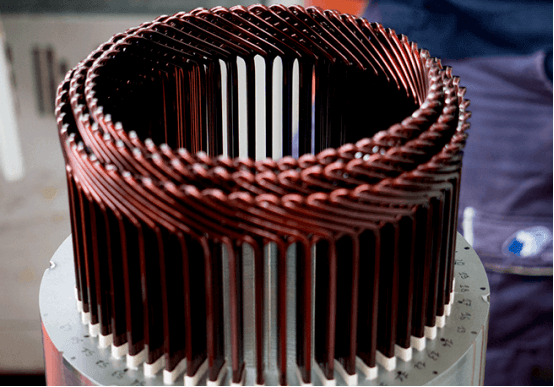

Hairpin (flat-wire) motors—supported by their clear technical superiority—have become the preferred choice for high-end and increasingly mainstream EV powertrain platforms. Compared with traditional round-wire motors, hairpin motors offer:

Over 70% slot fill factor (a 20–30% improvement)

Around 18% reduction in copper loss

More than 40% improvement in power density

These advantages directly contribute to higher energy efficiency, longer driving range, and improved motor performance, making hairpin technology a critical driver of the next wave of innovation in electric vehicle traction systems.

Despite the strong market demand and clear technical advantages, hairpin motor production faces significant manufacturing challenges. The technology requires highly complex processes and imposes exceptionally high production barriers. Under traditional manufacturing models, the industry commonly struggles with:

Low production efficiency

Insufficient process precision

Limited flexibility in production lines

Long changeover and retooling times

Poor material utilization

These bottlenecks make it difficult to achieve large-scale, cost-effective, and high-quality production of hairpin motors. As a result, they have become major obstacles to ensuring the security, stability, and global competitiveness of the EV hairpin motor supply chain.

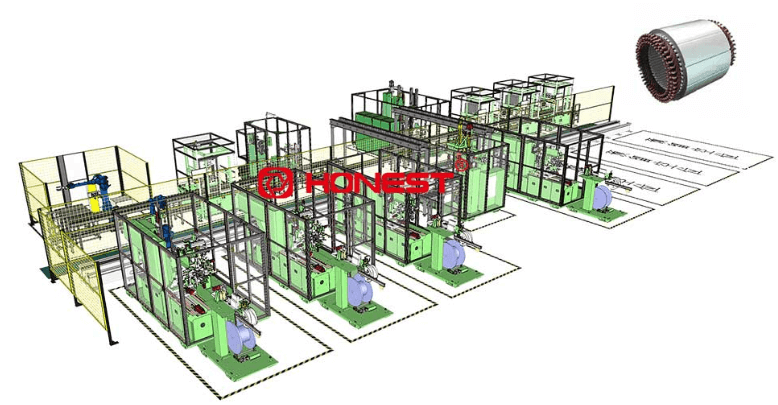

3. Breaking Barriers and Rebuilding the System: Seven Core Technology Clusters Driving Comprehensive Manufacturing Breakthroughs

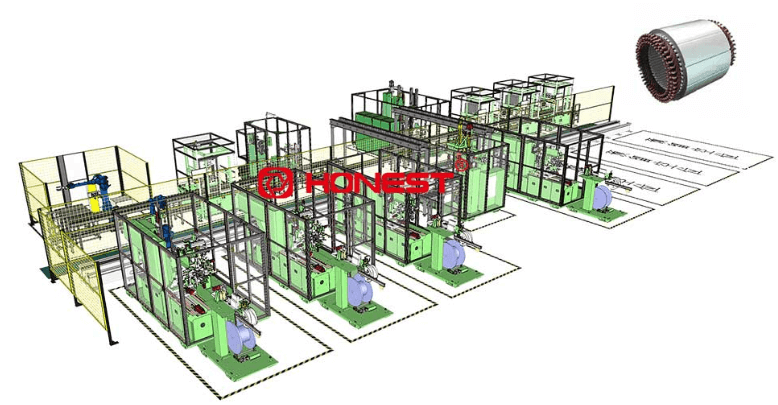

To address the common challenges faced across the industry, Honest Automation has continued to strengthen its R&D investment and has built a full-spectrum technology system covering advanced process research, high-end equipment development, intelligent system integration, and production data management.

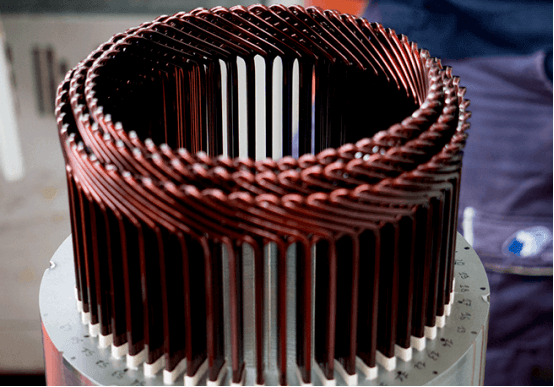

By systematically analyzing and reconstructing the entire manufacturing workflow of hairpin motors, we have achieved breakthrough progress across seven critical process stages of flat-wire motor production. This integrated technology cluster enables us to overcome long-standing manufacturing bottlenecks and elevate the performance, efficiency, and scalability of hairpin motor production lines.

(1) Intelligent Feeding and Flexible Adjustment System

To address the inefficiencies of traditional material feeding—such as long waiting times and low throughput—Honest Automation integrates AGV automated guided vehicles with a high-precision automatic wire-feeding system.

This coordinated setup enables continuous, zero-waiting material supply, increasing the overall equipment effectiveness (OEE) of the production line by over 20% and laying a solid foundation for 24/7 high-efficiency operation.

(2) High-Efficiency Changeover Mechanism and Mold Management Technology

This solution fundamentally overcomes the limitations of traditional changeovers, which are often slow and inflexible.

With our optimized mechanism, changeover efficiency increases by up to 400%, and the system can rapidly adapt to more than 36 different wire specifications, significantly enhancing the production line’s product compatibility and manufacturing flexibility.

(3) High-Speed Composite Forming Technology

Our high-speed composite forming process breaks through the industry’s long-standing conflict between speed and precision.

The forming cycle is reduced to 0.8 seconds per pin, while maintaining highly accurate control of wire flatness and consistency.

This ensures stable and high-quality pre-forming output for subsequent manufacturing stages.

(4) Multi-Spec Production Line Compatibility and Rapid Tooling Change

This system achieves integrated “material-in to product-out” operation, enabling seamless transitions between different product specifications.

Compared with traditional production lines, the changeover cycle is reduced by over 60%, effectively balancing the needs for high flexibility and high-speed mass production.

(5) Integrated Laser Stripping and Intelligent Dust Removal

Using four-direction synchronized laser stripping technology, the system achieves zero copper damage with a stripping cleanliness rate of 99.5%.

Paired with a high-efficiency dust collection unit achieving ≥98% capture efficiency, it eliminates the environmental pollution and material degradation issues associated with traditional stripping methods.

(6) China’s First Cut-Free Flat-Bending Technology

This breakthrough process eliminates the need for a conventional trimming step.

It delivers an end-face flatness accuracy of ±0.2 mm, saving over RMB 2 million in copper material per production line annually.

This innovation lays a solid technical foundation for next-generation winding technologies such as X-pin.

(7) Upgraded Vacuum Varnishing System

The enhanced varnishing system increases resin fill rate to ≥95% (a 5–8% improvement over traditional processes), while reducing energy consumption by 20%.

This significantly improves the motor’s insulation performance, durability, and long-term reliability.

4. Software Empowerment: Proprietary Platform Building Competitive Advantage

In addition to hardware innovations, Honest Automation has developed a proprietary universal software control platform, breaking the long-standing monopoly of foreign industrial software in the control of high-end equipment. This platform delivers multi-dimensional value to customers, including:

Rapid Program Creation: Accessible to basic-level operators, significantly reducing debugging time.

On-Site Quick Adjustments: Minimizes communication delays and improves problem response speed.

Real-Time Status Monitoring: Quickly identifies root causes of faults, reducing downtime.

Data Traceability and Management: Provides full-process data tracking to optimize production workflows and ensure seamless operations.

By shortening delivery times and reducing labor costs, this system not only enhances production efficiency and reduces failure rates but also generates tangible economic benefits for customers.

5. Technical Strength: Leading Patents and Performance Metrics

Sustained investment in innovation has established a robust intellectual property (IP) barrier for Honest Automation. Focusing on hairpin motor intelligent equipment, the company has built a comprehensive proprietary IP portfolio, including:

28 authorized patents: 8 invention patents, 19 utility models, and 1 software copyright

Beyond patents, the company’s equipment demonstrates outstanding performance across core technical indicators, fully surpassing industry standards and showcasing domestic leadership in hairpin motor manufacturing technology.

Economic Advantages: Reduced Costs and Higher Productivity

Compared with imported equipment, a single Honest Automation production line can reduce overall costs by 40–50%. Within the same investment scale, it achieves an approximately 40% increase in production capacity (based on an annual output of 350,000 units per line).

This translates into highly competitive return on investment (ROI) and enhanced market responsiveness for customers, making Honest Automation solutions a cost-effective and strategic choice for EV motor manufacturers.

6. Future Outlook: Leveraging Technology for a New Growth Curve

The recognition of “domestic leadership” not only validates past achievements but also serves as a gateway to the future. True technological leadership lies not in guarding a single advantage, but in transforming core process capabilities into transferable and evolvable “common technology platforms.”

Currently, Honest Automation is building technological reserves and equipment development capabilities in frontier fields such as hairpin motor, axial flux motor, humanoid robot joints, coreless motor, and frameless torque motor.

This means that the company’s accumulated precision hairpin manufacturing expertise is now spilling over beyond the NEV sector, extending into humanoid robotics, low-altitude aerial vehicles, and high-end industrial equipment, unlocking new and imaginative growth markets for the company.

From a breakthrough in a single core technology, to leading intelligent equipment, and now to a common technology platform empowering multiple industries, every step taken by Honest Automation has been solid and deliberate.

This technology achievement evaluation not only certifies the company’s technical excellence but also recognizes Honest Automation’s responsibility and commitment as a leading Chinese high-end equipment manufacturer—leveraging innovation and execution to support national industrial self-reliance, safety, and transformation.

Looking ahead, Honest Automation will continue to drive technological innovation, providing a stronger and smarter equipment foundation for China’s intelligent manufacturing. Together with industry partners, the company will actively contribute to the global electrification and intelligentization revolution.