As electric vehicles continue to scale globally, hairpin motors (flat wire motors) have become the preferred solution for high-performance and high-efficiency electric drive systems. Compared to traditional round-wire motors, hairpin motors offer higher slot fill factors, improved thermal performance, and greater power density.

However, these advantages come at the cost of significantly increased manufacturing complexity. As a result, successful mass production of hairpin motor depends not only on motor design, but also on advanced automation equipment and integrated production systems.

This article provides an overview of the hairpin motor manufacturing process, the key automation technologies involved, and the broader automation equipment landscape, from a production and scalability perspective.

1. Why Hairpin Motors Are Becoming the Mainstream EV Technology

Hairpin motors are widely adopted in EV traction systems due to:

Higher efficiency and power density

Better thermal dissipation

Improved suitability for high-speed and high-voltage applications

Major OEMs and Tier 1 suppliers increasingly specify hairpin stators in their next-generation electric drive platforms. However, these benefits can only be realized at scale if the manufacturing process is stable, repeatable, and highly automated.

2. Core Hairpin Motor Manufacturing Process

2.1 Slot Insulation Insertion

The process begins with slot insulation to protect conductors from the stator core. At high production volumes, automation is essential to ensure:

Consistent insulation positioning

No damage to lamination edges

High cycle time stability

2.2 Hairpin Forming

Flat copper conductors are precisely bent into hairpin shapes. This step requires:

Tight dimensional control

Minimal surface damage

High repeatability

Advanced forming equipment ensures uniform geometry, which is critical for downstream insertion and welding quality.

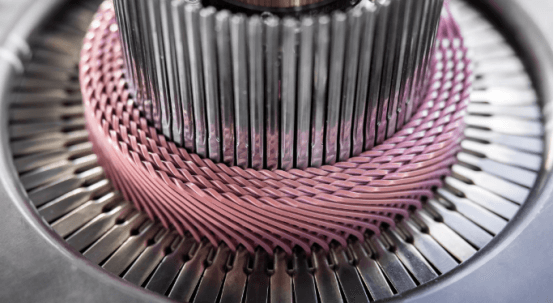

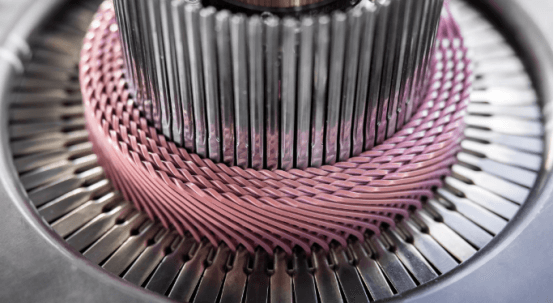

2.3 Hairpin Insertion

Hairpin insertion is one of the most critical and technically demanding steps. Challenges include:

Accurate pin positioning

Avoiding insulation damage

Managing tight tolerances

Many manufacturers rely on fully automated hairpin insertion systems to achieve stable high-volume output.

2.4 End-Winding Forming and Welding

After insertion, the hairpin ends are formed and welded to create electrical connections. This stage directly impacts:

Electrical resistance balance

Thermal performance

Long-term reliability

Automated forming and welding systems with inline monitoring are essential for mass production.

2.5 Electrical Testing and Quality Control

Inline testing—including resistance, insulation, and dimensional checks—ensures defects are detected early, preventing costly downstream failures.

3. Automation Equipment Technologies for Hairpin Motor Production

Hairpin motor production relies on multiple categories of automation equipment:

Hairpin forming and insertion machines

End-winding forming and welding systems

Rotor assembly and magnet insertion equipment

Inline electrical and visual inspection systems

Rather than isolated machines, integrated production lines are increasingly preferred to ensure consistency, throughput, and traceability.

4. Overview of the Hairpin Motor Automation Equipment Landscape

From a manufacturing perspective, automation equipment providers can be broadly categorized into:

Single-process equipment specialists, focusing on individual operations such as forming or welding

Modular automation suppliers, offering configurable production modules

Turnkey production line integrators, capable of delivering complete hairpin stator and motor assembly lines

Each approach serves different production strategies and capacity requirements.

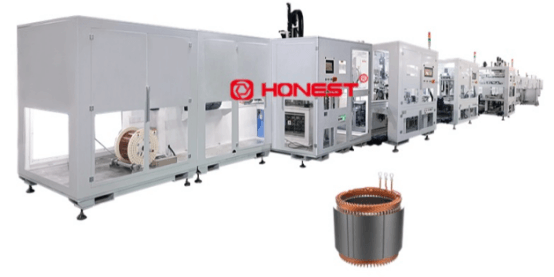

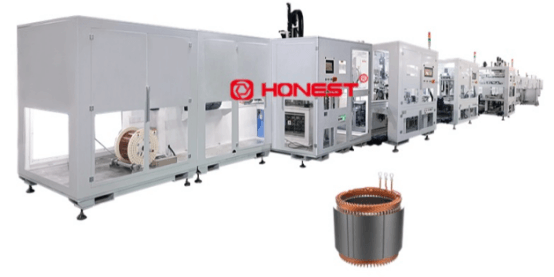

5. Honest Automation’s Role in Hairpin Motor Manufacturing

Honest Automation specializes in complete hairpin motor automation solutions, covering:

Hairpin stator winding and insertion

End-winding forming and welding

Rotor assembly and motor assembly

Inline testing and data traceability

By focusing on system-level integration, Honest Automation helps EV motor manufacturers bridge the gap between prototype development and high-volume production, ensuring scalability, yield stability, and long-term manufacturing reliability.

6. Key Considerations When Selecting Automation Equipment

When planning hairpin motor production, manufacturers should evaluate:

Scalability and future motor variants

Process stability and yield performance

Level of automation and labor dependency

System integration and data traceability

Experience of the automation partner in EV motor production

Early alignment between motor design and manufacturing system design is critical for successful industrialization.

Hairpin motor represent the future of high-performance EV drive systems, but their complexity demands advanced, well-integrated automation solutions. Understanding the manufacturing process and automation equipment landscape enables manufacturers to make informed decisions and avoid costly scaling challenges.

With its expertise in hairpin motor production lines and system integration, Honest Automation supports global EV manufacturers in achieving efficient, reliable, and scalable mass production.

Frequently Asked Questions About Hairpin Motor Manufacturing

Q1: Why is hairpin motor manufacturing more complex than round-wire motors?

A: Hairpin motors require precise forming, insertion, and welding of flat copper conductors, which significantly increases process complexity and tolerance requirements.

Q2: What equipment is required for hairpin motor mass production?

A: Hairpin forming machines, insertion systems, welding equipment, inline inspection, and integrated automation lines are essential.

Q3: How do manufacturers scale hairpin motor production efficiently?

A: By adopting fully automated, integrated production lines with real-time quality monitoring and data traceability.

Q4: What role do automation partners play in EV motor manufacturing?

A: Automation partners like Honest Automation provide system-level solutions that ensure consistency, scalability, and production efficiency.