The rotor winding machine is a key equipment in the motor manufacturing process. Its performance and reliability directly affect the quality of motor products. With the development of industrial automation, the demand for rotor winding machines continues to grow, and different industries have increasing requirements for their accuracy, speed, and customization. Choosing an excellent rotor winding machine manufacturer can improve production efficiency and ensure the long-term stable operation of the equipment. However, faced with many manufacturers and a wide variety of products, how to make the right choice has become a major challenge for many companies. This article aims to provide companies with a detailed purchasing guide to help them identify excellent rotor winding machine manufacturers and make wise purchasing decisions.

1. Basic knowledge of rotor winding machine

Before choosing the right manufacturer, it is essential to understand the basics of rotor winding machines. Here are the core contents of this equipment:

The rotor winding machine is a device specially used to wind electromagnetic wire onto the motor rotor. It is a crucial link in the motor manufacturing process because the winding accuracy directly affects the motor's operating efficiency, durability and energy consumption performance. In modern motor manufacturing, rotor winding machines usually have the characteristics of high degree of automation, high winding accuracy and high speed to meet the needs of industrial large-scale production.

-

Classification of rotor winding machines

Rotor winding machines can be classified according to their degree of automation and application areas. Common types include:

Fully automatic rotor winding machine: suitable for large-scale, high-precision production. The operator only needs to set the parameters simply, and the equipment will automatically complete the winding process.

Semi-automatic winding machine: suitable for small and medium batch production, some operations require manual intervention, and the cost performance is relatively high.

Manual winding machine: mainly used for small batch or special customized production, with more manual control and high flexibility.

In addition, rotor winding machines can also be classified according to the size and scope of application of the equipment, including small, medium and large winding machines, which are adapted to the production needs of motors of different scales and types. Rotor winding machines can also be assembled into fully automatic or semi-automatic rotor assembly lines.

-

Important technical indicators of rotor winding machine

When purchasing a rotor winding machine, companies should pay special attention to the following key technical indicators:

Winding accuracy: The tightness and uniformity of winding directly affect the performance of the motor. High-quality equipment can maintain a high degree of consistency and ensure that the wires are neatly arranged after winding.

Winding speed: The core indicator of production efficiency, directly affecting the factory's production capacity. When communicating with the equipment manufacturer to make a scheme, you need to provide the corresponding output, and the equipment manufacturer will provide a corresponding customized plan based on the output.

Programmability: Modern winding machines are often equipped with a programmable controller (PLC) that can be programmed according to the needs of different motors to increase production flexibility.

Stability and durability of equipment: The stability of equipment during long-term operation is an important factor in measuring its quality.

2. Key Factors in Evaluating Quality Rotor Winding Machine Manufacturers

After understanding the basics of rotor winding machines, the next step is how to evaluate the capabilities of manufacturers. This section will explore in detail the performance of manufacturers in multiple dimensions.

Manufacturer’s experience and technical capabilities

Experienced manufacturers usually understand customer needs better and have the ability to cope with complex technical challenges. Companies should give priority to manufacturers with many years of experience in the field of motor winding equipment. They are not only more mature in equipment design but also can respond quickly to market changes and technological innovations. In addition, the manufacturer's R&D capabilities are also a key factor. Companies with strong technological innovation capabilities are often able to provide more advanced and efficient equipment.

Manufacturer's qualifications and certifications

Choosing a manufacturer with relevant industry qualifications and certifications can ensure the quality and safety of the equipment. For example, ISO quality management system certification is an important standard for evaluating the manufacturer's quality control level. Other certifications such as CE (European safety standards) and UL (US safety standards) can also ensure the compliance of equipment in different markets.

Manufacturer's equipment customization capabilities

The production needs of enterprises may be different, and whether the manufacturer can provide customized solutions is an important consideration. Excellent manufacturers usually have strong design capabilities and can design and manufacture special equipment according to the special needs of customers. At the same time, the flexibility and scalability of the equipment are also key points to measure its customization capabilities.

Manufacturer's product quality and performance stability

High-quality equipment must have a high degree of stability and durability. Manufacturers should use high-quality materials and precision components to ensure the service life of the equipment and low failure rate. In addition, whether the manufacturer has conducted rigorous testing and inspections on the equipment to ensure that its performance meets industry standards is also an important aspect to focus on when choosing.

Manufacturer Service and Support

Good pre-sales and after-sales services are the hallmarks of a quality manufacturer. Pre-sales services include providing technical advice and solution design to help customers choose the most suitable equipment. After-sales services cover equipment maintenance, troubleshooting, and spare parts supply. If the manufacturer can provide comprehensive training support to help operators quickly get started with the equipment, it will also greatly improve the efficiency of equipment use. If you choose an overseas equipment supplier, you also need to consider whether there are local agents and after-sales teams to provide technical support to reduce the time cost of equipment downtime and waiting.

Manufacturer's market reputation

By examining the reputation of manufacturers in the market, you can more intuitively evaluate the quality of their equipment and service level. Enterprises can refer to other customers' feedback and success stories to judge the actual performance of manufacturers. Find out whether the equipment vendor's cooperative customers are well-known companies and whether they have cooperated with them many times. This will accurately judge their service attitude and quality after cooperation, rather than feeling that the communication is good before the transaction and irresponsible after the cooperation.

3. How to evaluate the cost performsnce of rotor winding machines

Cost performance is one of the core considerations when enterprises choose equipment. The following are important factors affecting the cost performance of rotor winding machines:

Initial purchase cost of the equipment

The initial purchase cost of automatic rotor winding machine of different types and models may vary greatly. High-end equipment usually has more functions, higher precision and automation, suitable for large-scale production, but the purchase cost is relatively high. Enterprises need to reasonably choose equipment models according to their own production scale and actual needs.

Equipment operating efficiency

Efficient winding machines can significantly increase production capacity, reduce labor costs, and speed up production cycles. The winding speed, ease of operation, and production stability of the equipment will directly affect its operating efficiency.

Long-term maintenance costs

High-quality equipment is designed to minimize maintenance requirements, but any mechanical equipment will inevitably wear out during long-term operation. Therefore, understanding the maintenance cost of the equipment, including the replacement cycle of wearing parts and repair costs, is the key to evaluating cost-effectiveness.

Energy consumption and environmental protection of equipment

With the rise in energy costs and the improvement of environmental protection requirements, the energy consumption level of equipment has gradually become an important factor affecting cost performance. Enterprises should give priority to equipment with low energy consumption and high efficiency, which can not only reduce operating costs but also help enterprises fulfill their environmental protection responsibilities.

4. Common Mistakes to Avoid When Selecting a Manufacturer

When selecting a manufacturer, companies should avoid the following common mistakes:

Excessive pursuit of low prices

Although price is an important factor in choosing equipment, excessive pursuit of low prices may lead to a decline in equipment quality and service level. Low-priced equipment may have problems such as simple design and use of inferior materials, resulting in a short service life and frequent failures.

Ignoring the manufacturer’s after-sales service capabilities

After-sales service is the key to ensuring the long-term normal operation of equipment. If the manufacturer does not provide adequate after-sales service, when problems occur during the operation of the equipment, the company may face production suspension or high repair costs.

Not paying attention to the manufacturer's market reputation

Although some emerging manufacturers have low prices, their technology accumulation and market verification are insufficient. Enterprises should consider carefully when choosing to avoid losses due to equipment quality problems.

Lack of in-depth understanding of equipment technical requirements

If enterprises do not have sufficient understanding of their own technical needs when purchasing, they may purchase unsuitable equipment. Therefore, it is the key to avoid purchasing mistakes to have a deep understanding of their own production needs and ensure that the equipment functions meet actual needs.

Therefore, by comprehensively considering the manufacturer's technical capabilities, qualification certification, product quality, service support and market reputation, enterprises can choose high-quality rotor winding machine manufacturers. To ensure the success of procurement, enterprises should clarify their own needs, fully examine the product characteristics of different manufacturers, and make reasonable choices based on cost performance.

Establishing long-term cooperative relationships with high-quality manufacturers can not only ensure a stable supply of equipment, but also obtain continuous technical support during future production upgrades, helping enterprises achieve sustainable development.

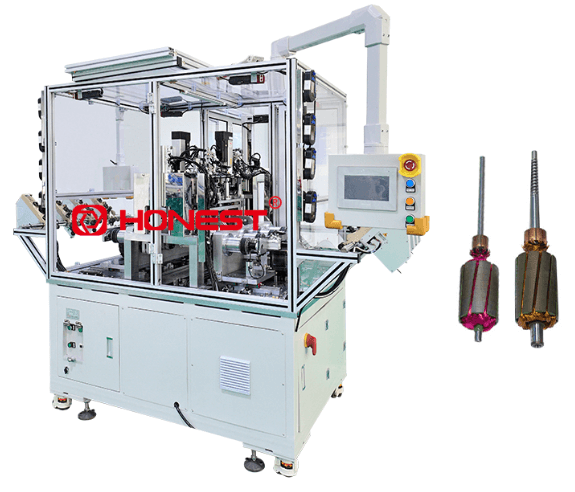

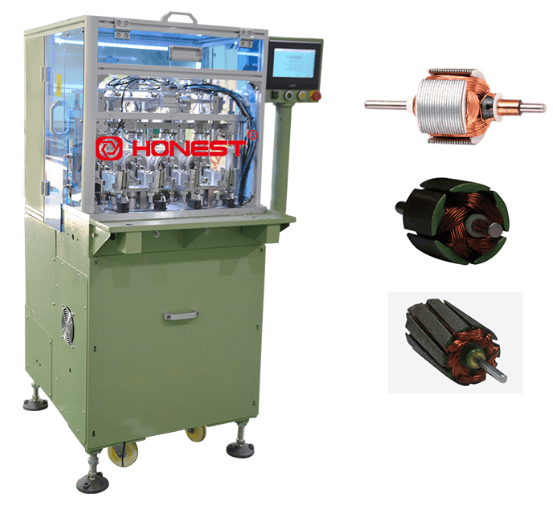

HONEST Automation is an internationally renowned rotor winding machine manufacturer, focusing on the research and development and production of rotor winding machines for more than 18 years. It has provided more than 1,000 rotor winding machines to many motor and automobile brand manufacturers. It can provide customized solutions according to customer needs and solve the difficulties of rotor winding and assembly for customers. Welcome to consult and get customized automation equipment schemes and quotations for free.