As the global automotive industry accelerates toward electrification, integrated electric drive systems such as ISG (Integrated Starter Generator) and BSG (Belt Starter Generator) motors are playing a pivotal role in mild-hybrid and full-hybrid powertrains. For Tier-1 suppliers and OEMs developing multi-platform EV systems, the demand for high-flexibility assembly lines is rapidly increasing.

This article explores the key technical considerations for assembling ISG and BSG motors and how a flexible, intelligent production line can significantly enhance manufacturing adaptability, efficiency, and consistency.

1. What Are ISG and BSG Motors?

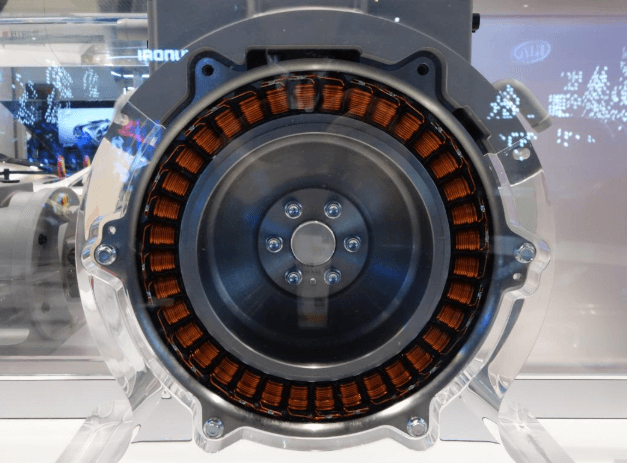

ISG Motors

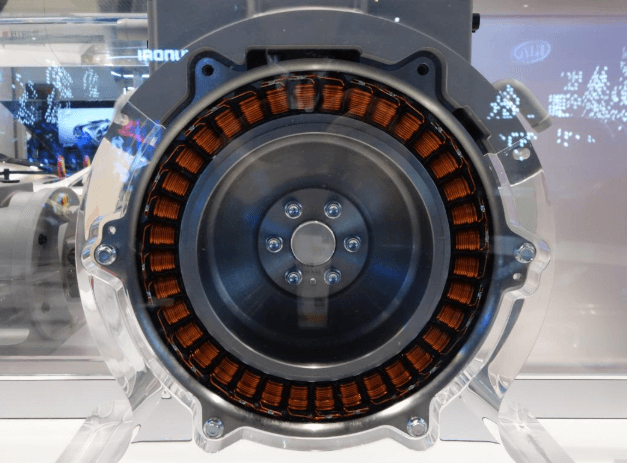

ISG motors are directly integrated into the drivetrain, typically positioned between the internal combustion engine (ICE) and transmission. They function as both a starter and a generator, capable of delivering additional torque during acceleration and regenerative braking during deceleration.

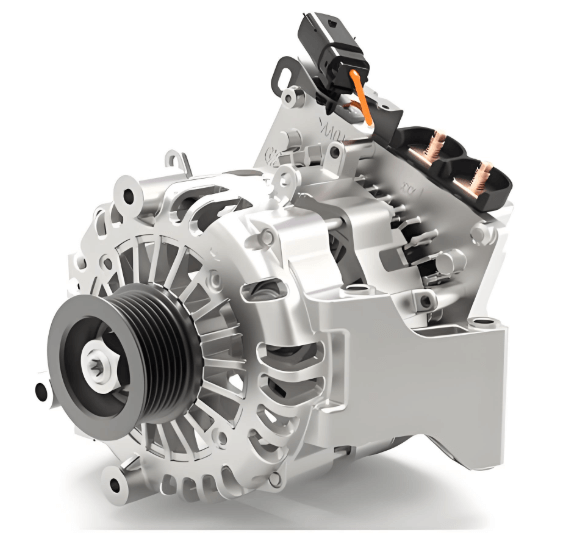

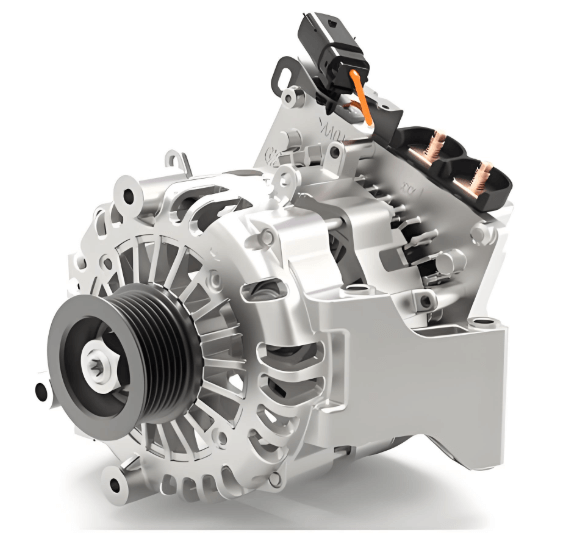

BSG Motors

BSG motors are connected to the engine crankshaft via a belt drive. While not as efficient as ISG in terms of power transmission, they offer a simpler and more cost-effective way to introduce hybrid functionality to conventional powertrains.

Key Functions:

Engine start-stop operation

Regenerative braking and energy recovery

Electric torque assist

Improved fuel efficiency and reduced emissions

2. Assembly Challenges for ISG/BSG Motors

The assembly of ISG and BSG motors is inherently complex due to several factors:

Design Variability: These motors vary significantly in size, winding configuration, and cooling structures across platforms.

Precision Requirements: Rotor balancing, stator winding, and shaft alignment must meet tight tolerances to ensure performance and durability.

System Integration: ISG/BSG units must be assembled with gearboxes, belts, clutches, and electronic control units, requiring precise mechanical and electrical synchronization.

Cycle Time Demands: OEMs seek shorter takt times without sacrificing quality or traceability.

3. Flexible Assembly Line Solutions

A future-proof ISG/BSG motor assembly line must be:

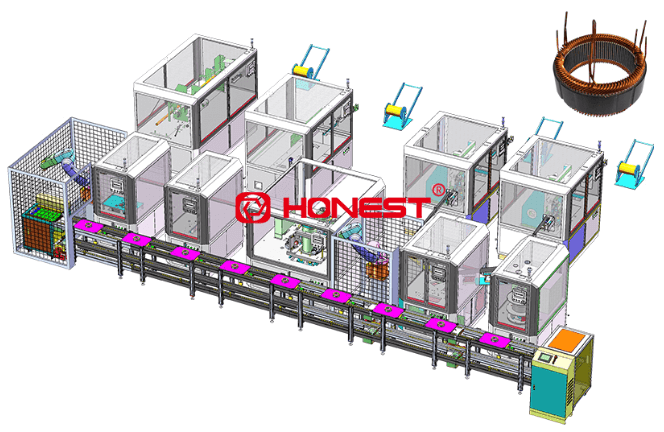

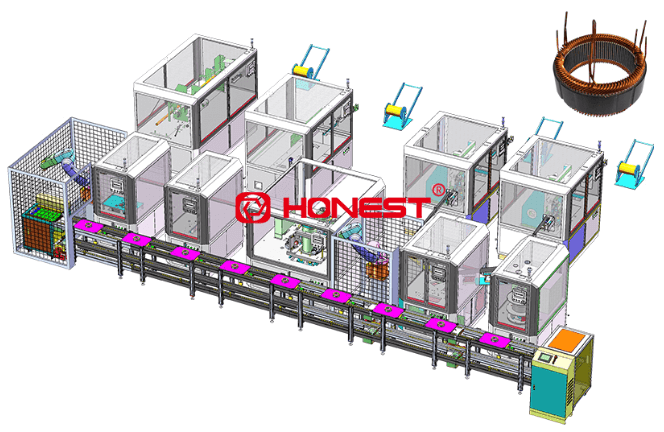

Modular

Each process station—winding, insertion, rotor assembly, end-of-line testing—is designed as an independent module. This allows the line to scale and reconfigure for various product types with minimal downtime.

Intelligent

Equipped with vision systems, torque control, auto-calibration, and MES connectivity for real-time monitoring and traceability.

Multi-Platform Compatible

The line should support multiple frame sizes and motor designs, enabling the same equipment to serve multiple vehicle models or platforms.

Key Stations in the Line Include paper inserting, wire making, twisting, welding, etc.

4. Real-World Application Scenarios

It is suitable for the production of hairpin motor stators, such as BSG motors, automobile generators, etc. The output can reach 600 units in 8 hours. The servo motor adopts bus control, the key parts are processed independently with precision equipment, and the standard parts are all from top international brands.

Intelligent functions: life management of key components, face recognition, real-time traceability, uploading and distribution of production data, and docking with MES systems.

5. Benefits for Global Manufacturers

Investing in flexible ISG/BSG motor assembly lines yields long-term strategic benefits:

Reduced Capital Cost: One line, multiple products

Faster Time to Market: From design to SOP in under 6 months

Increased Yield & Consistency: Real-time quality monitoring reduces rework

Future Scalability: Supports platform evolution (from 48V to higher-voltage systems)

6. Why Choose HONEST Automation as Your Assembly Line Partner?

HONEST Automation specializes in intelligent motor automation equipment with a proven track record in delivering flexible, high-precision solutions for global EV and hybrid programs. Our advantages include:

End-to-end project support: from line design to after-sales service.

Localized installation, training, and technical support across Asia, Europe, and North America.

Rich experience in cooperation with automobile manufacturers, auto parts and motor manufacturers.

Support proofing, manual production, semi-automatic and fully automatic batch production, customized according to customer needs.

ISG and BSG motors are critical components in the transition to hybrid and electric mobility. As platforms diversify, having a flexible, modular assembly line is no longer optional—it's a competitive necessity.

Interested in upgrading your motor production line?

Contact HONEST Automation for a customized ISG and BSG motor assembly line solution and quotation.