-

- EV Motor Manufacturing Assembly Line

- BLDC Motor Assembly Line

- Stator Assembly Line

- Rotor Magnet Inserting Machine

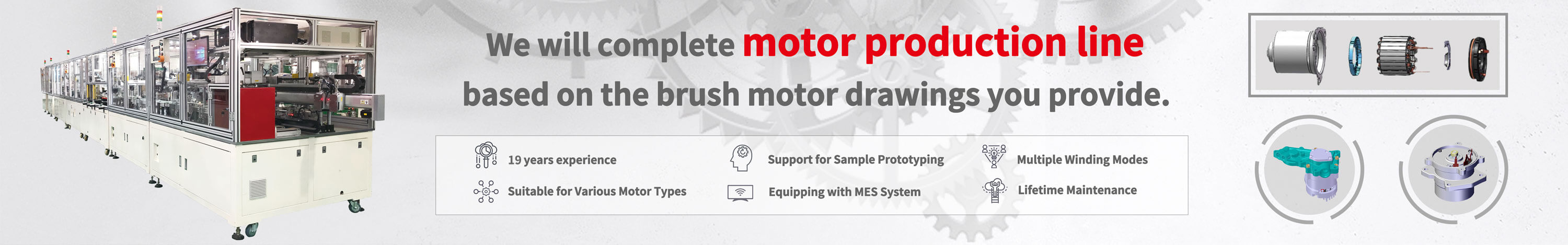

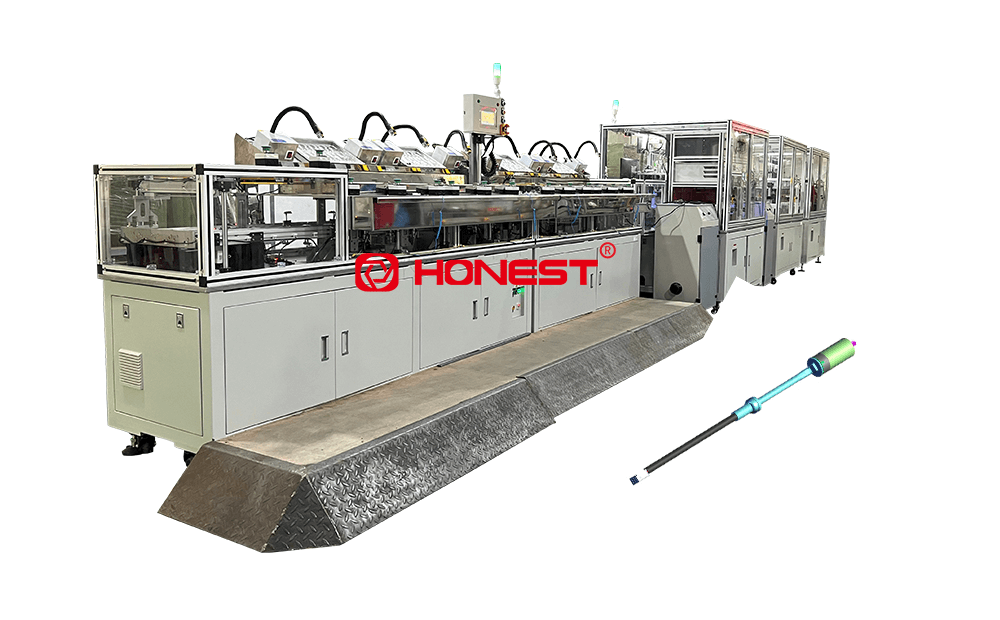

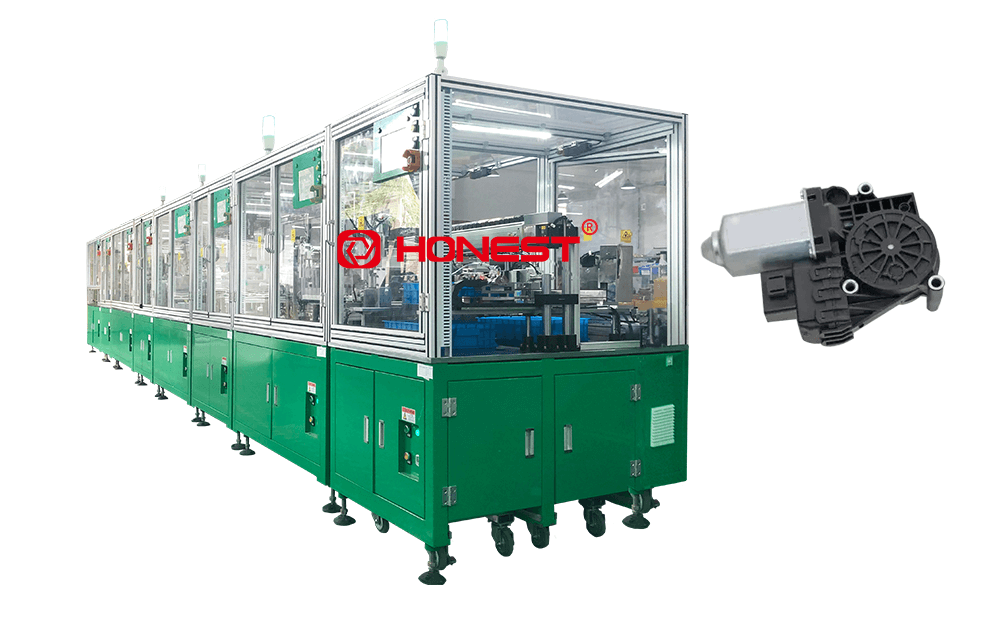

- Brush Motor Assembly Line

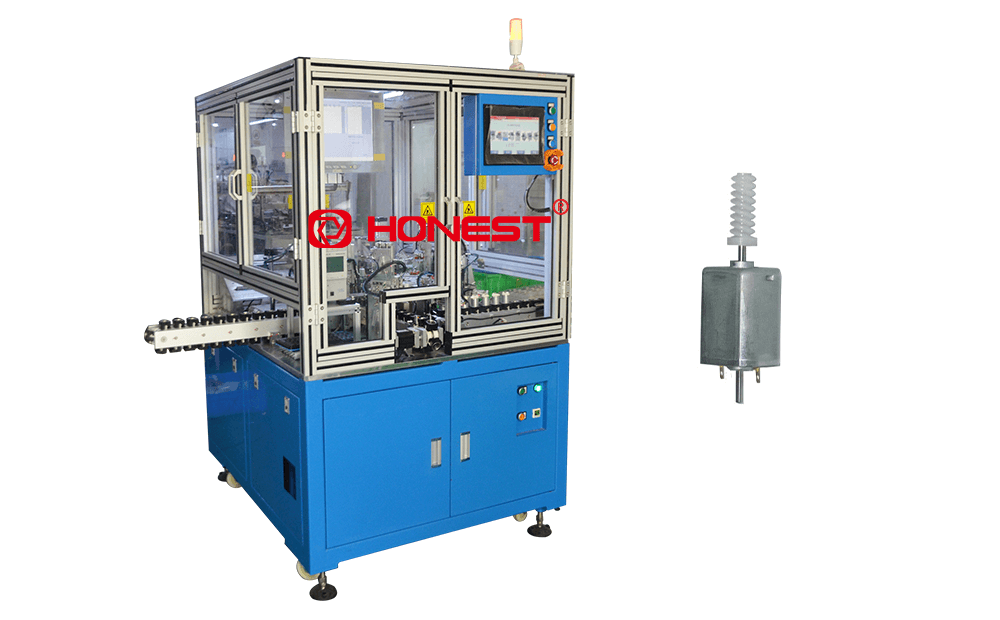

- Inductor Winding Machine

- Motor Winding Machine

- Non-Cutting Hairpin Stator Twisting Machine

- Drive Motor Stator Production Line

- Hairpin Stator Assembly Line

- X-pin Motor Production Line

- Drive Motor Assembly Line

- Hairpin Motor Stator Winding & Assembly Line

- Hairpin Motor Automatic Production Line

- Automobile BSG Motor Stator Assembly Line

- Humanoid Robot Motor Production Line

- Condenser Fan Motor Assembly Line

- Automotive EPS Motor Production Line

- Urea Pump Motor Assembly Line

- Electronic Oil Pump Motor Assembly Line

- Automotive EPS Motor Assembly Line

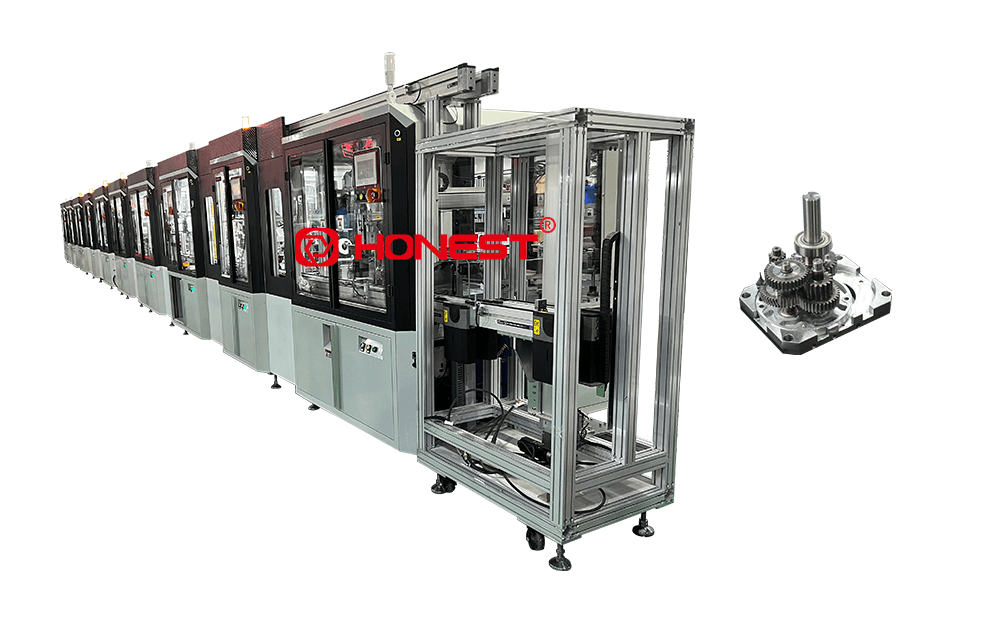

- Automotive Electronic Oil Pump Production Line

- Fully Automated Production Line for Brushless Motors

- Segmented Stator Production Line

- Brushless Stator Production Line

- Automotive Compressor Motor Assembly Line

- Commercial Vehicle Water Pump Stator Assembly Line

- EPS Motor Stator Production Line

- Split Motor Compressor Stator Assembly Line

- Automobile Air Pump Brushless Motor Stator Production Line

- Automotive Water Pump Brushless Motor Stator Assembly Line

- Rotor Magnet Insert Magnetization Equipment

- BLDC Rotor Magnet Insertion Assembly Line

- Motor Rotor Magnet Insertion Machine

- Rotor Magnet Assembly Machine

- Brushless Motor Rotor Assembly Line

- Drive Motor Rotor Production Line

- Electric Vehicle Motor Rotor Assembly Line

- Automotive Air Suspension Motor Production Line

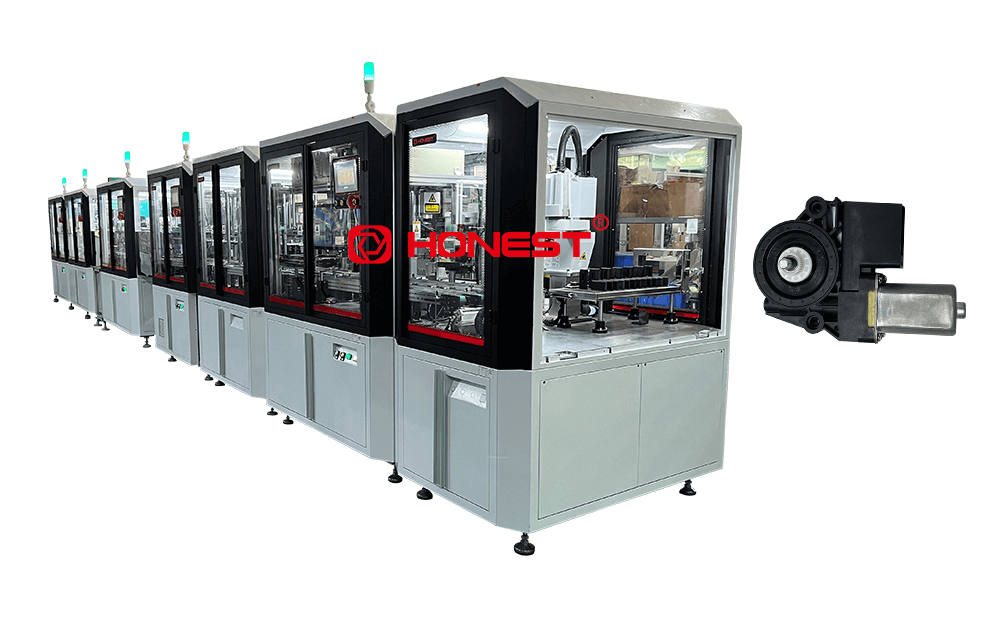

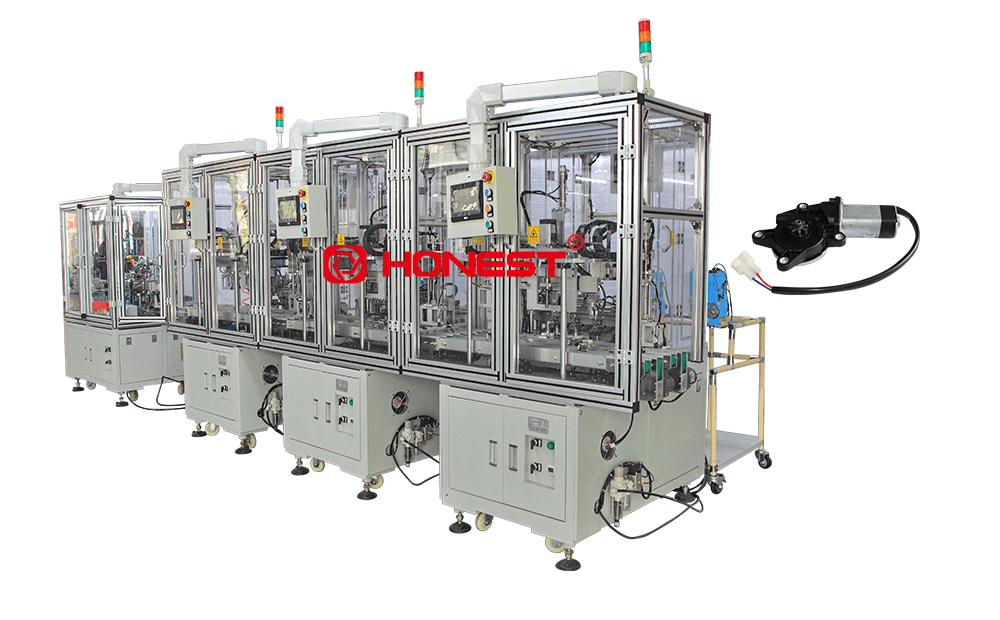

- Car Riding Seat Motor Assembly Line

- Automobile Electric Sunroof Motor Assembly Line

- Automobile Water Pump Motor Assembly Line

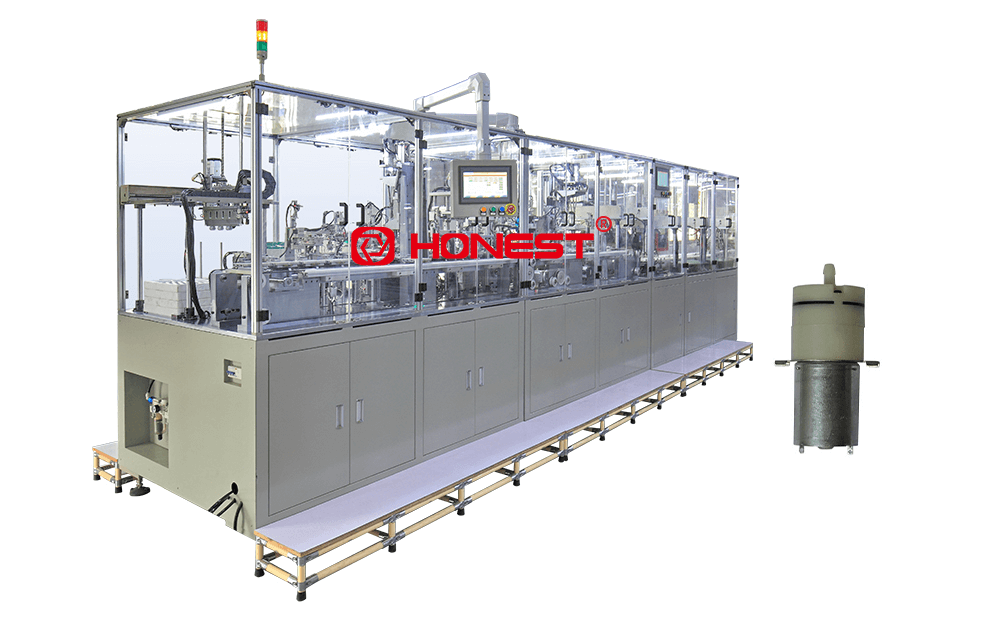

- Motor Automation Production Line

- Automobile Motor Production Line

- Automobile Door Lock Motor Assembly Equipment

- Motor Automatic Assembly Line

- Network Transformer Automatic Winding Machine

- Common Mode Inductor Winding Equipment

- Tcore Integrated Inductor Winding Machine

- NR SMD Inductor Fully Automatic Winding Machine

- Common Mode Choke Four-Axis Winding Machine

- NR Inductor Dispensing Machine

- Inductor SMD Test Packaging Machine

- Automatic Flyer Armature Winding Machine

- Air Conditioning Compressor Stator Winding Machine

- Stator Heating Assembly Winding Equipment

- Three Station Block Stator Winding Machine

- Hub Motor Stator Winding Machine

- Stator High Precision Wire Winding Machine

- Dual Station Block Flat Wire Winding Machine

- Brushless Stator Block Winding Machine