-

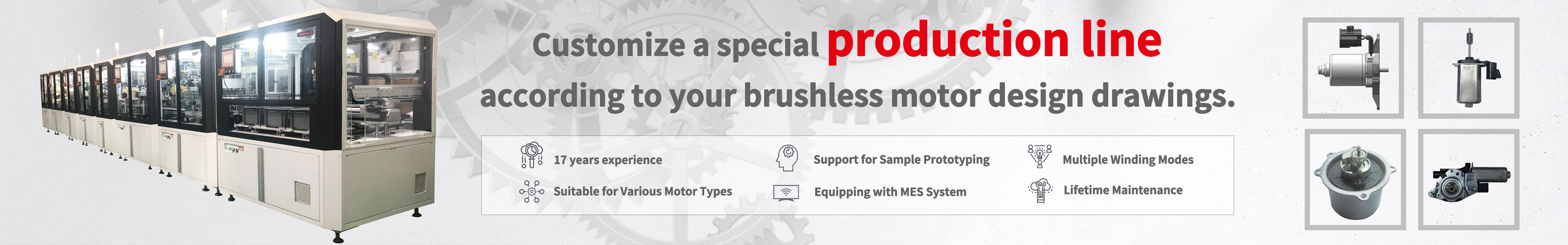

- EV Motor Manufacturing Assembly Line

- BLDC Motor Assembly Line

- Stator Assembly Line

- Brush Motor Assembly Line

- Inductor Winding Machine

- Motor Winding Machine

- X-pin Motor Production Line

- Drive Motor Assembly Line

- Drive Motor Rotor Production Line

- Hairpin Motor Stator Winding & Assembly Line

- Hairpin Motor Automatic Production Line

- Automobile BSG Motor Stator Assembly Line

- Hub Motor Stator Winding Machine

- Electric Vehicle Motor Rotor Assembly Line

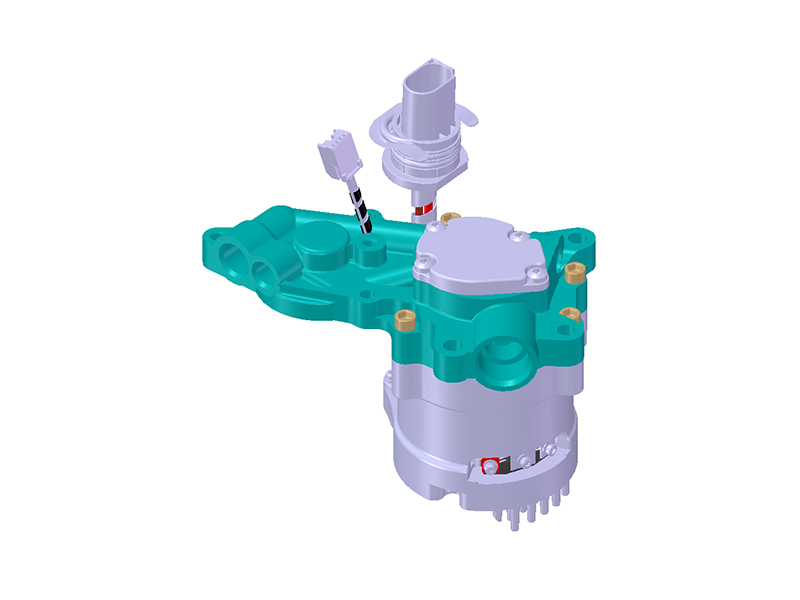

- Electronic Oil Pump Motor Assembly Line

- Automotive Air Suspension Motor Production Line

- Automotive EPS Motor Assembly Line

- Automotive Electronic Oil Pump Production Line

- Fully Automated Production Line for Brushless Motors

- Automobile Fan Motor Assembly Line

- SG Damping Regulator Stepper Motor Assembly Line

- Stepper Motor Assembly Equipment

- EPS Motor Stator Production Line

- Brushless Motor Rotor Assembly Line

- Split Motor Compressor Stator Assembly Line

- Automobile Air Pump Brushless Motor Stator Production Line

- Automotive Water Pump Brushless Motor Stator Assembly Line

- Brushless Motor Block Stator Production Line

- Automobile Water Pump Stator Production Line

- Automobile Oil Pump Brushless Motor Stator Production Line

- Car Riding Seat Motor Assembly Line

- Automobile Electric Sunroof Motor Assembly Line

- Automobile Water Pump Motor Assembly Line

- Motor Automation Production Line

- Automobile Motor Production Line

- Automobile Door Lock Motor Assembly Equipment

- Motor Automatic Assembly Line

- Automobile Trunk Motor Production Equipment

- Network Transformer Automatic Winding Machine

- Common Mode Inductor Winding Equipment

- Tcore Integrated Inductor Winding Machine

- NR SMD Inductor Fully Automatic Winding Machine

- Common Mode Choke Four-Axis Winding Machine

- NR Inductor Dispensing Machine

- Inductor SMD Test Packaging Machine

- Air Conditioning Compressor Stator Winding Machine

- Stator Heating Assembly Winding Equipment

- Three Station Block Stator Winding Machine

- Stator High Precision Wire Winding Machine

- Dual Station Block Flat Wire Winding Machine

- Brushless Stator Block Winding Machine

- Brushless Three Needle Winding Machine

- Double Flying Fork Chain Plate Winding Machine