With the continuous development of auto technology, intelligence has been a significant developing trend in the vehicle industry. In numerous intelligent configurations, the tailgate motor as a configuration to improve the cars’ convenience and safety, is more and more favored by consumers.

The rear door usually refers to the motor drive system used to control the vehicle’s rear door including the rear tailgate and car trunk lid. The motor allows the rear door to be opened and closed electrically, improving the convenience and comfort of the vehicle.

The Core Function of the Tailgate Motor

A. Automated Opening and Closing: Users can remotely control the opening and closing of the rear door through in-vehicle buttons or remote key, which greatly improves portability of use;

B. Hover Function: During door movement, the user can press the control button at any time to pause the rear door at any position for easy loading and unloading of items;

C. Height Memory: Users can set the opening height of the rear door, the system will memorize the height and automatically reach the preset position the next time it is opened;

D. Anti-pinch Function: If the rear door encounters an obstacle during the closing process, the motor will immediately stop working or move in reverse to prevent passengers from being pinched or items damaged;

E. Kick Sensor Activation: Some models provide a kick sensor function. When the user makes a kick motion under the rear bumper, the rear door will automatically open. The function is particularly useful when hands are inconvenient;

F. Follow-up Function: When the user manually pulls the back door, the motor will assist in completing the door opening action, reducing the driver’s labor intensity.

The Working Principle of the Tailgate Motor

The working principle of the rear door is relatively simple. It mainly consists of a motor, gearbox, transmission mechanism, and control module. When the users issue an open or close command, the control module sends a signal to the motor, which rotates and drives the rear door to open or close through the gearbox and transmission mechanism. During the process, the motor’s position sensors will provide real-time feedback on the position of the rear door to ensure precise control of the door.

The System Composition of the Tailgate Motor

A. Lift Motor: Responsible for providing the power needed to open the door, usually installed near the hinge of the rear door;

B. Door Lock Motor: Controls the locking and unlocking of the rear door to ensure that the door can be firmly locked when closed;

C. Control Module(PLGN/RDM): It is the brain of the whole system, responsible for receiving user instructions, processing sensor signals, and controlling the motor;

D. Kick Sensor: Used to detect kick movements to achieve contactless door opening;

E. Anti-pinch Strip: Installed on the edge of the rear door to provide additional protection in areas that cannot be detected by the anti-pinch algorithm.

The Technology Development of the Tailgate Motor

With the development of technology, automobile tailgate motors are developing in the direction of low cost and high performance. On the one hand, manufacturers reduce costs by optimizing designs and using more efficient materials; on the other hand, they improve the response speed and stability of the system by improving control algorithms and motor technology. In addition, the trend of intelligence and networking also allows the tailgate motor to be better integrated with other vehicle systems such as smart keys, and vehicle infotainment systems, providing richer functions and a better user experience.

The Maintenance and Safety of the Tailgate Motor

While auto tailgate motors are typically designed with durability in mind, regular maintenance is still necessary. Users should regularly check the wear of the motor and transmission mechanism and clean the sensor to ensure its normal operation. When encountering a system failure, you should promptly go to a professional maintenance point for inspection and repair to ensure safe use.

In all, the vehicle’s tailgate motor not only improves the convenience and comfort of the vehicle but is also an important manifestation of the intelligence of the car. With the continuous advancement of technology, further car tailgate motors will be more intelligent, efficient, and safe, bringing users a better driving experience.

The Tailgate Motor Production Line of HONEST

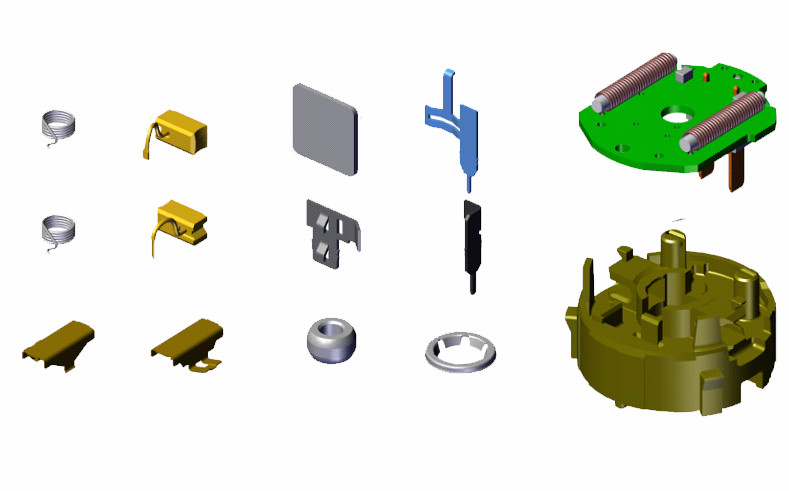

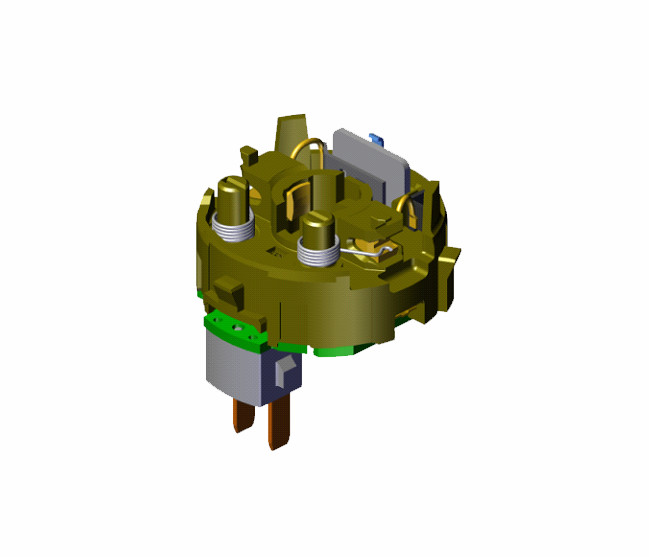

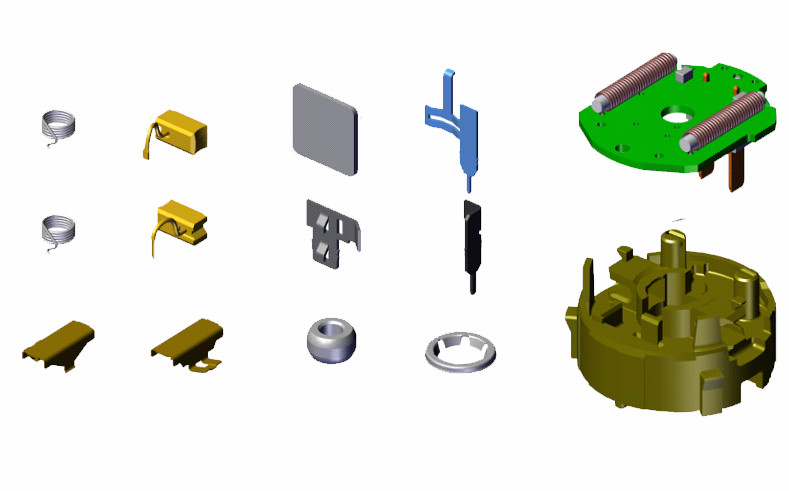

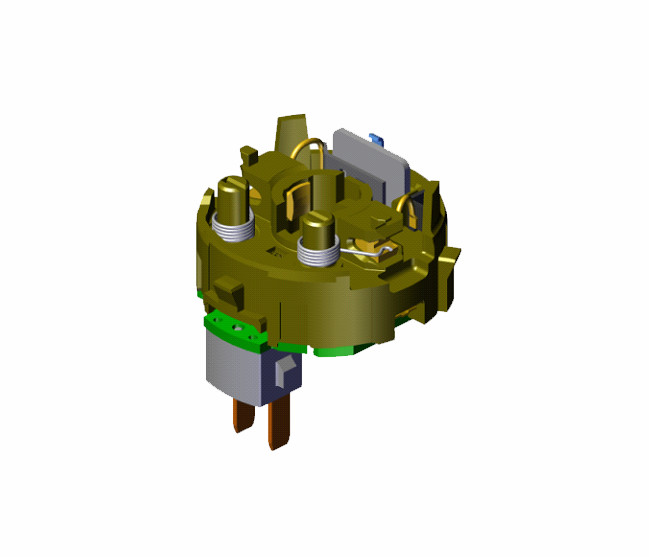

The production line is used in the field of automobile electric tailgates. It consists of a rotor assembly section, a magnetic bottom assembly section, and a motor assembly section, providing a one-stop solution for the manufacturing of its core component motor.

The application of automation and intelligence not only can cope with the disappearing demographic dividend and solve the labor cost, technology, management, and other problems of labor-intensive enterprises; but also it can improve the production efficiency of enterprises and make product performance more stable, let the products have a broader and stable market. At the same time, the modular and flexible design also makes the solution more flexible in application and has wide product compatibility, which greatly reduces the company’s production replacement costs.

The Advantages

A. The equipment is equipped with high-precision sensors, visual inspection systems, and so on, to prevent leakage, under-installation, wrong installation, and post-installation quality inspection;

B. In terms of safety protection and error prevention:

a. The equipment is equipped with special safety gratings, safety door locks, and so on, for personal safety protection;

b. The equipment has a safety protection function for opening the door;

c. The equipment has an air pressure safety protection function;

d. The equipment will prompt various misoperations, bad conditions, and so on, in real-time;

e. When the equipment is abnormal, an abnormal alarm will be prompted on the screen to indicate the abnormal location to facilitate manual processing;

C. The degree of process integration is high, the equipment size is small, and materials are saved;

D. Modular and flexible design, on the one hand, can make the entire line layout more flexible, beautiful, and concise; on the other hand, it can make the production line more versatile and have a wider compatibility range;

E. The commutator turning process is equipped with front and back turning pins to ensure the precision of the turning pins.

If you want the tailgate motor assembly line, please consult us for quotes and solutions.