With the rapid development of the automotive industry, the electric door handle, as one of the standard features of smart cars, is increasingly valued for its design and functionality. The electric door handle motor, an essential component of smart vehicles, provides users with a more comfortable and convenient driving experience.

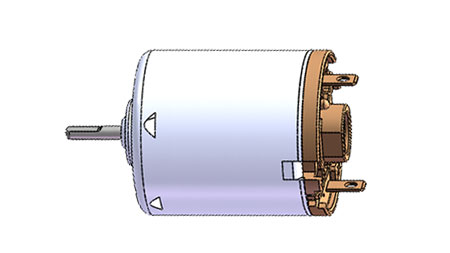

The electric door handle motor is a small motor installed within the vehicle door handle, converting electrical energy into mechanical energy to achieve the automatic opening and closing of the car door.

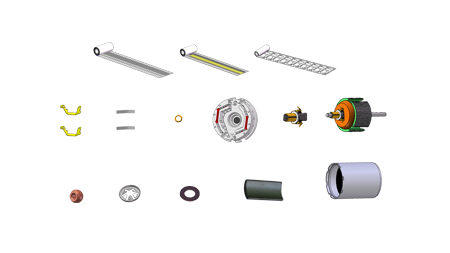

A. Components of Electric Door Handle Motor

Motor: The core component responsible for converting electrical energy into mechanical energy, providing power for the opening and closing of the door handle.

Transmission Mechanism: It includes gears, belts, or levers, used to convert the motor’s rotational movement into the linear movement of the door handle.

Control Unit: It contains a microcontroller and related electronic components, used to receive commands and control the motor’s start, stop, and speed.

Sensors: Such as position sensors, force sensors, and so on, are used to detect the position state of the door handle and the user’s operating force.

Power Supply Module: It provides a stable power supply for the entire system.

Actuator: In some systems, in addition to the motor, there may also be hydraulic or pneumatic actuators to enhance power output.

Protection Devices: Such as overload protection, short circuit protection, etc., to ensure the safety of the system in abnormal conditions.

Interface: The interface for communication with other electronic systems of the vehicle.

B. Working Principle of Electric Door Handle Motor

The electric door handle motor typically uses a direct current (DC) motor as the driving source, receiving signals from the vehicle control unit through an electronic controller to achieve automatic ejection and retraction of the door handle. The details are as follows:

User Interaction: The user triggers the sensor by touching or pulling the door handle, which converts the signal into an electrical signal sent to the control unit.

Signal Processing: After receiving the signal, the control unit decides whether to start the motor and at what speed and force to execute based on preset logic and algorithms.

Motor Startup: The control unit sends a start signal to the motor, which begins to rotate according to the instructions.

Power Transmission: The rotation of the motor is converted into linear movement of the door handle through the transmission mechanism, achieving the opening or closing of the door.

Position Feedback: Position sensors monitor the position of the door handle in real time and provide feedback information to the control unit to ensure the door handle reaches the correct position.

Force Detection: Force sensors detect the force of the user’s operation, and the control unit adjusts the output of the motor according to the size of the force to adapt to different user’s operating habits.

Safety Protection: during the movement of the door handle, if an obstacle or abnormal condition is encountered, the protection device will trigger, stopping the motor operation to prevent damage.

System Feedback: Throughout the process, the control unit continuously monitors the system status and communicates with other vehicle systems through the interface, ensuring overall coordination and responsiveness.

C. Design Considerations for Electric Door Handle Motors

When designing an electric door handle motor, it is necessary to meet requirements such as miniaturization, high torque, low noise, high reliability, and high safety. The following outlines the design points from aspects such as motor selection, reducer design, and worm gear mechanism design.

Motor and Transmission System

Motor Selection: Choose a compact motor with sufficient torque, matching speed with the reducer, high efficiency, and low noise.

Reducer Design: Design a high-efficiency, low-noise reducer to ensure smooth output and match the motor speed.

Mechanism and Materials

Worm Gear Mechanism: Use high-strength, wear-resistant materials to ensure high precision and efficiency, meeting the travel requirements of the door handle.

Clutch Design: Select the appropriate type of clutch according to the requirements to ensure sufficient torque and rapid response.

Control and Safety

Control System Design: Use a microcontroller or PLC with comprehensive control functions, including opening and closing control, limit detection, and safety protection.

Limit Switch Design: Choose high-precision, high-reliability limit switches to ensure accurate opening and closing of the door handle and anti-pinch function.

User Experience and Environmental Adaptability

Human-Machine Interface: Design an intuitive and easy-to-use human-machine interface for user operation and settings.

Environmental Adaptability: Conduct waterproof, dustproof, and heat dissipation designs to ensure stable operation of the motor and transmission system in various environments.

Electromagnetic Compatibility and Maintenance

Electromagnetic Compatibility: Ensure all components comply with electromagnetic compatibility standards to reduce electromagnetic interference.

Maintenance Convenience: Design structures that are easy to install and maintain, simplifying the later service process.

In summary, the design of the electric door handle motor should comprehensively consider factors such as volume, torque, noise, reliability, safety, and control functions, and meet the performance and environmental requirements of the entire machine. With the continuous advancement of technology, the functions of the electric door handle motor will become more intelligent, bringing users a more convenient and comfortable driving experience.

D. Features and Benefits of Electric Door Handle Motors

Automatic Door Handle Operation: The electric door handle motor can automatically open and close the door handle by receiving signals from buttons, sensors, and other detectors.

Intelligent Control: Integrated with microcontrollers and Hall sensors, the electric door handle motor achieves more intelligent control, such as keyless entry, automatic door closing, and anti-pinch features.

Customization: The electric door handle motor can be customized according to user needs, allowing users to adjust the speed and angle of door handle operation in emergencies, as well as designs to prevent tampering, fire, and explosion.

Compared to traditional mechanical door handles, electric door handle motors offer advantages such as greater convenience, intelligence, aesthetics, humanization, safety, and reliability. Based on these advantages, they play an important role in smart home and automotive applications.

E. Electric Door Handle Motor Production Equipment

As an essential part of automotive intelligence and electrification, the production equipment and processes for electric door handle motors are continuously evolving and innovating. Here are some key production equipment and processes:

High-Precision Machine Equipment: Used for machining precision parts inside the motor. Such as rotors and stators, which ensure efficient operation and stability of the motor.

Automated Assembly Lines: Automated assembly technology can improve production efficiency and product quality, reducing manual operation errors, suitable for mass production of electric door handle motors.

Laser Welding Equipment: Laser welding technology can enhance welding efficiency and quality, particularly in the production of micro-motors, achieving high-precision welding requirements.

Motor Testing Equipment: Used to test motor performance parameters, such as torque, speed, and efficiency, ensuring products meet design standards.

Customized Solutions: HONEST Automation provides customized services tailored to customer needs, focusing on actual customer requirements to produce equipment that meets user needs.

If you need automotive door handle motor assembly equipment, please consult us for customized solutions and quotes.