Globally, electric vehicles are experiencing robust growth, with the market size expanding year by year. As the core component of electric vehicles, drive motors are also rapidly developing. The development trends and technological innovations of drive motors have become the focus of attention in the industry. This article aims to delve into the development trends of drive motors for electric vehicles and analyze aspects such as technological innovation and market dynamics.

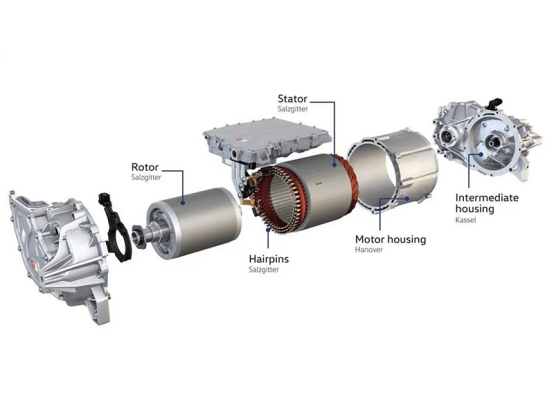

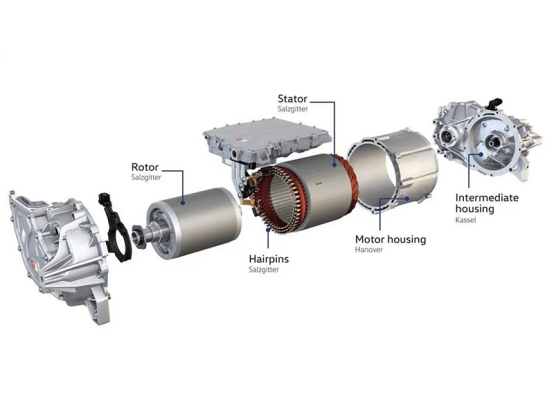

The electric vehicle (EV) drive motor is an electrical device that converts electrical energy into mechanical energy to provide the driving force for the vehicle. It is mainly composed of the stator, rotor, housing, connector, rotary transformers, and other components. It is the power source of new electrical vehicles, and its performance will affect the vehicle’s climbing ability, acceleration ability and other driving performance indicators. In the continuous pursuit of high performance by electric vehicles, the design of drive motors tends to develop in the direction of lightweight, compact design, long life, and high reliability. These characteristics not only ensure the powerful power output but also ensure the stability of vehicle operation, thereby improving the riding experience.

With the continuous expansion of the electric vehicle market, the market competition for drive motors is becoming more intense. Motor manufacturers are investing in the research and development of new energy drive motors. In the fierce market competition, to stand out and capture market share, motor manufacturers need to continuously enhance their technical strength. This includes optimizing existing technologies and exploring and developing advanced technologies to ensure that their products meet the needs of the market and consumers in terms of performance, efficiency, and cost. Currently, market participants in the electric vehicle motor drive system industry are mainly divided into two categories: vehicle manufacturers and third-party suppliers.

what's more, with the increasing policy support and market demand for electric vehicles from countries around the world, the innovation and development of drive motor technology will directly affect the overall performance and market competitiveness of electric vehicles. For instance, the Inflation Reduction Act (IRA) passed by the U.S. government provides subsidies for electric vehicles assembled in the United States, including tax credits; the Canadian government offers purchase subsidies to reduce the cost for consumers to buy electric vehicles and has set requirements for the installation of charging facilities in new construction and renovation projects; the German government and businesses jointly fund subsidies for the purchase of electric vehicles, with a subsidy of 4,000 euros for pure electric vehicles and fuel cell vehicles per car, and a subsidy of 3,000 euros for plug-in hybrid vehicles per car, as well as a policy of exempting pure electric vehicles from motor vehicle tax for ten years. These policies can effectively increase the purchase volume of electric vehicles, attract more car manufacturers to develop electric vehicles, and enhance market competitiveness.

With technological innovation and market dynamics, the electric vehicle drive motor has the following development trends.

High Power Density

The development trends of drive motors for electric vehicles are primarily characterized by the pursuit of higher power density, which is a critical performance indicator for these motors. Due to the limited space for vehicle layout and battery capacity of electric vehicles, there are strict limitations on the size of the motor system, so the design of drive motors will develop towards smaller volume, lighter mass, and higher power density. To achieve high power density of the motor, there are ways to improve the design of the magnetic circuit, the use of high permeability and high conductivity materials, and a reasonable choice of electrical loads.

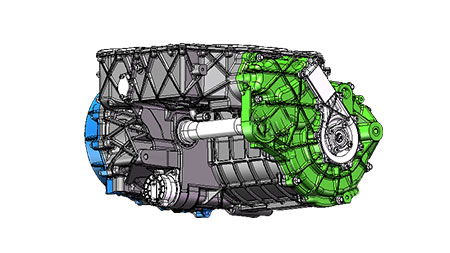

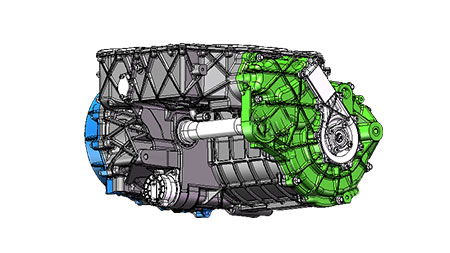

Integrated Electric Drive System

An integrated electric drive system is a system that integrates key components such as motors, transmissions, and controllers, reducing the overall volume and weight of the system, thereby improving its overall performance and efficiency. Integration has the following advantages: achieving tighter synergy between components to optimize overall performance, reducing energy losses, and enhancing energy efficiency. The integrated design responds to the electric vehicle industry’s pursuit of lightweight motors.

Application of New Materials

The application of new materials in the field of EV drive motors is propelling further enhancements in motor performance. High-temperature superconducting materials and new types of permanent magnet materials are at the forefront of these advancements:

High-Temperature Superconducting Materials: Known for their ability to conduct electricity with extremely low resistance, these materials can significantly improve the efficiency and power density of motors. Their use in motors reduces energy loss and enhances operational efficiency, thereby improving the overall performance of EVs.

Advanced Permanent Magnet Materials: With their high magnetic energy density and coercivity, these new materials are extensively used in permanent magnet synchronous motors (PMSMs). The adoption of such materials not only boosts the motor's torque output but also contributes to a reduction in the motor's size and weight. This supports the trend towards lightweight and high-performance electric vehicles.

Popularization of Permanent Magnet Synchronous Motors (PMSMs)

PMSMs are increasingly becoming the preferred choice for electric vehicles due to their high power density, high operating efficiency, compact structure, substantial torque, and excellent speed control performance.

1. High Power Density: PMSMs typically utilize magnetic steel made from rare earth neodymium-iron-boron processed through powder metallurgy, which possesses superior magnetic properties. Once magnetized, these magnets do not require additional external energy to maintain a strong magnetic field. The permanent nature of the magnetic field eliminates the need for excitation circuits, allowing for a smaller form factor and lighter weight. Underrated power conditions with similar cooling and insulation materials, the power density of PMSMs is typically more than double that of induction asynchronous motors.

2. High Operating Efficiency: The rotor of a PMSM does not require electrical current, reducing energy losses and increasing efficiency.

3. Substantial Torque: Within the rated current range, increasing the current can rapidly boost the torque of a PMSM. The rotating magnetic field formed by the three-phase alternating current in the stator is also more stable, resulting in smaller torque pulsations. Particularly at low speeds with high torque requirements, PMSMs have a distinct advantage over asynchronous induction motors.

4. Excellent Speed Control: The relationship between electricity, magnetism, and force in PMSMs is simpler than in induction asynchronous motors, making them easier to control and regulate speed. While the state equations of asynchronous motors are of the fourth order with coupled rotor and stator equations, PMSMs have second-order state equations with the permanent magnet field being independent. This makes control at both low and high speeds (above the rated speed) significantly easier compared to asynchronous motors.

Intelligent Control Systems

With the advancement of the Internet of Things (IoT) and artificial intelligence (AI), intelligent control systems are being increasingly applied in the field of electric vehicle drive motors. These systems optimize energy efficiency and ensure that the motors operate in the best condition by monitoring and adjusting the motor's operating state in real-time. Intelligent control can not only enhance the performance of the motor, but also reduce the failure rates through predictive maintenance, improve the reliability of the motor, and extend the service life of the drive motor.

Cost-Effectiveness

As technology matures and production scales up, the manufacturing cost of motors is decreasing. The application of new materials such as high-performance permanent magnet materials and lightweight materials not only improves the performance of motors, but also helps to reduce the manufacturing cost of motors. The reduction in costs makes electric vehicles more affordable for consumers and promotes their popularity in the market. At the same time, the improvement in cost-effectiveness has attracted more motor manufacturers to invest in the research and development and production of electric vehicle drive motors, bringing fierce market competition and further promoting the development of the industry.

Environmental Friendliness and Sustainability

In the design and manufacturing process of electric vehicle drive motors, manufacturers are placing an increasing emphasis on the sustainability of their products. This includes a focus on the environmental friendliness and recycling of materials. By establishing an effective recycling system, valuable components in motors can be recycled and reused, reducing material waste, and contributing to resource conservation and environmental protection. In addition, motor manufacturers are also intensifying their research and development efforts on product energy efficiency, reducing energy consumption by improving motor efficiency, and promoting green travel.

The development trends of electric vehicle drive motors indicate that technological innovation and market demand are the key drivers of industry development. As global policy support and market demand for new electric vehicles increase, the drive motor industry is also growing. To capture market share in the rapidly developing industry and fierce market competition, choosing a high-quality and reliable motor manufacturer is crucial.

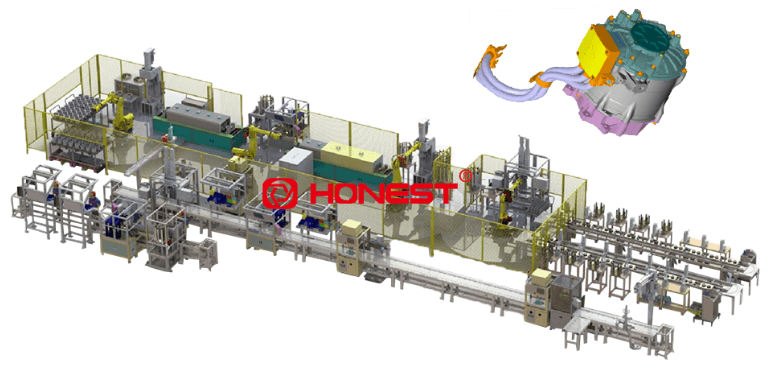

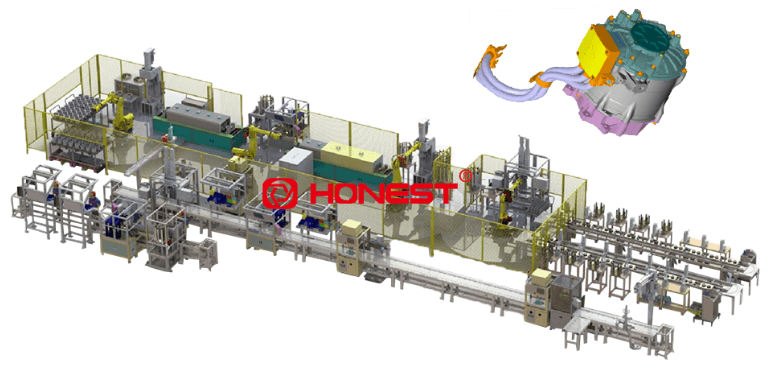

As a motor intelligent equipment manufacturing company established over a decade, HONEST has extensive experience in the manufacturing of production equipment for electric vehicle drive motors. We are dedicated to providing customized non-standard solutions to meet specific electric vehicle drive motor requirements, ensuring a high degree of alignment between customer requirements and the final product. If you have any requirements for an EV drive motor assembly line, please feel free to contact us at any time. Our professional team looks forward to hearing from you.